Multifunctional self-repairing polyurethane reticulate pattern coating and preparation method thereof

A polyurethane coating and self-repairing technology, applied in polyurea/polyurethane coatings, chitin polysaccharide coatings, anti-corrosion coatings, etc., can solve problems such as inability to protect the coating, and achieve the effect of improving repair efficiency and comprehensiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

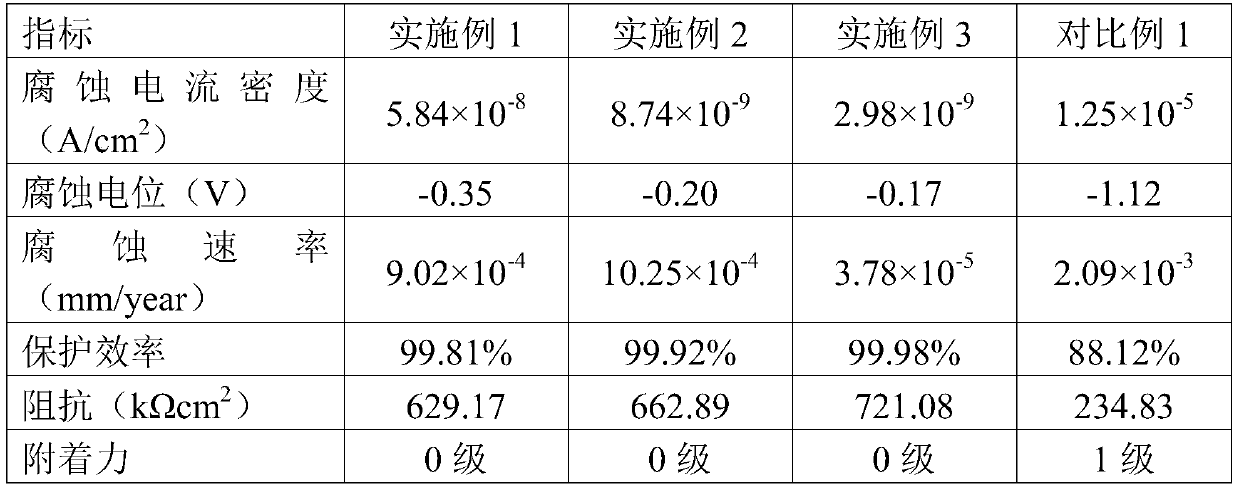

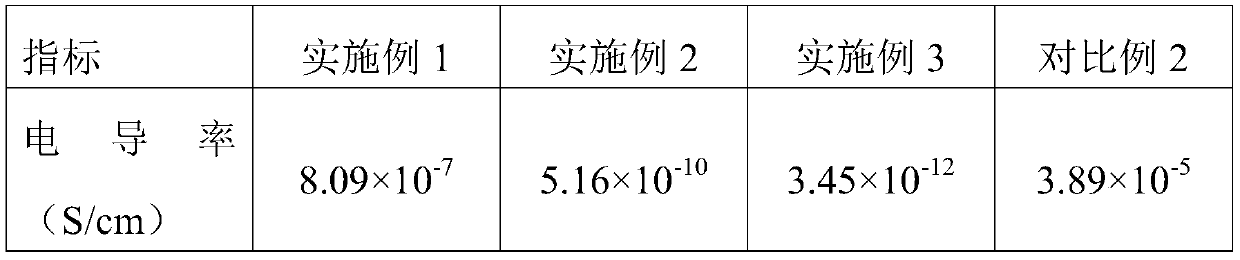

Examples

Embodiment 1

[0051] A multifunctional self-repairing polyurethane textured coating provided in this embodiment is prepared from the following raw materials in parts by weight:

[0052] 30 parts of hexanediol polycarbonate;

[0053] 20 parts of isophorone diisocyanate;

[0054] 5 parts of dimethylolpropionic acid;

[0055] 2 parts of triethylamine;

[0056] 0.5 parts of diethylene glycol;

[0057] 0.2 parts of hydrazine monohydrate;

[0058] 20 parts of nano metformin / 8-hydroxyquinoline-Mg-Cu layered polyethyleneimine;

[0059] 20 parts of cerium molybdate / barium tungstate-NaY zeolite molecular sieve;

[0060] Leveling agent 7 parts;

[0061] 5 parts of pigment.

[0062] Wherein, the preparation method of cerium molybdate / barium tungstate-NaY zeolite molecular sieve comprises the following steps:

[0063] 1. In a condensing environment, dissolve cerium molybdate powder and barium tungstate powder in distilled water to form a 0.3M cerium molybdate solution and a 0.3M barium tungstate...

Embodiment 2

[0081] A multifunctional self-repairing polyurethane textured coating provided in this embodiment is prepared from the following raw materials in parts by weight:

[0082] 35 parts of hexanediol polycarbonate;

[0083] 25 parts of isophorone diisocyanate;

[0084] 8 parts of dimethylolpropionic acid;

[0085] 2.3 parts of triethylamine;

[0086] 0.7 parts of diethylene glycol;

[0087] 0.35 parts of hydrazine monohydrate;

[0088] Nano 1-H-benzotriazole-4-sulfonic acid-Zn-Fe layered polyaniline 22.5 parts;

[0089] Lanthanum vanadate-modified chitosan 22.5 parts;

[0090] 8.5 parts of leveling agent;

[0091] 7.5 parts of pigment.

[0092] Wherein, the preparation method of lanthanum vanadate-modified chitosan comprises the following steps:

[0093] 1. In a condensing environment, dissolve lanthanum vanadate in distilled water to form a metal-inorganic salt solution with a concentration of 0.4M. Immerse 8g of porous material in 160ml of lanthanum vanadate solution, and u...

Embodiment 3

[0111] A multifunctional self-repairing polyurethane textured coating provided in this embodiment is prepared from the following raw materials in parts by weight:

[0112] 40 parts of hexanediol polycarbonate;

[0113] 30 parts of isophorone diisocyanate;

[0114] 10 parts of dimethylolpropionic acid;

[0115] 2.5 parts of triethylamine;

[0116] 1 part of diethylene glycol;

[0117] 0.5 parts of hydrazine monohydrate;

[0118] 25 parts of nanometer 4,4'-methyl bis(cyclohexyl isocyanate)-Zn-Al layered polyvinylpyrrolidone;

[0119] Cadmium borate-modified montmorillonite 25 parts;

[0120] 10 parts of leveling agent;

[0121] 10 parts of pigment.

[0122] Wherein, the preparation method of described cadmium borate-modified montmorillonite comprises the following steps:

[0123] 1. In a condensing environment, dissolve cadmium borate in distilled water to form a cadmium borate solution with a concentration of 0.5M, immerse 10g of porous material in 200ml of cadmium bora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com