A kind of artificial periosteum loaded with deferoxamine and its preparation method

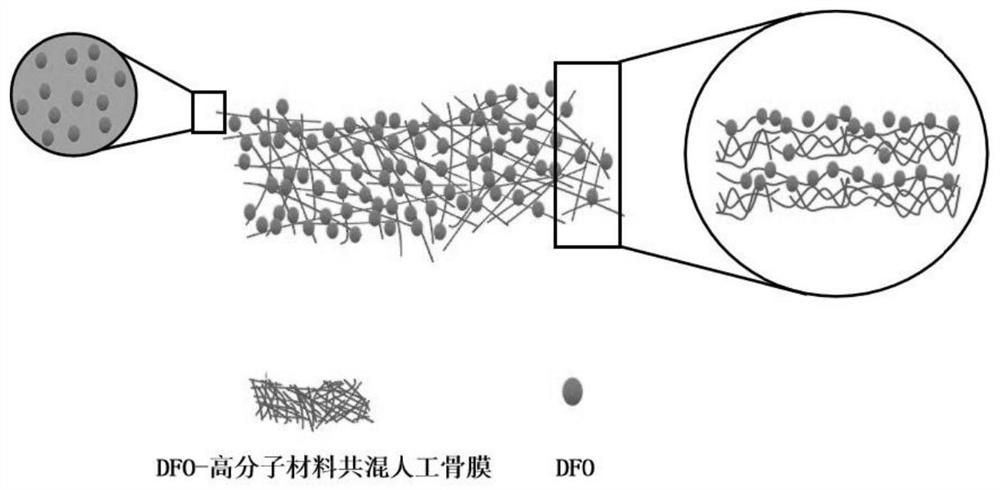

An artificial bone and electrospinning technology, which is applied in the field of biomedical materials, can solve the problems of difficulty in ensuring the demand of bone tissue and limited release of DFO, so as to prolong the action time of drugs, prevent infection and heterotopic ossification, and reduce the risk of infection. Beneficial for nutrient exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

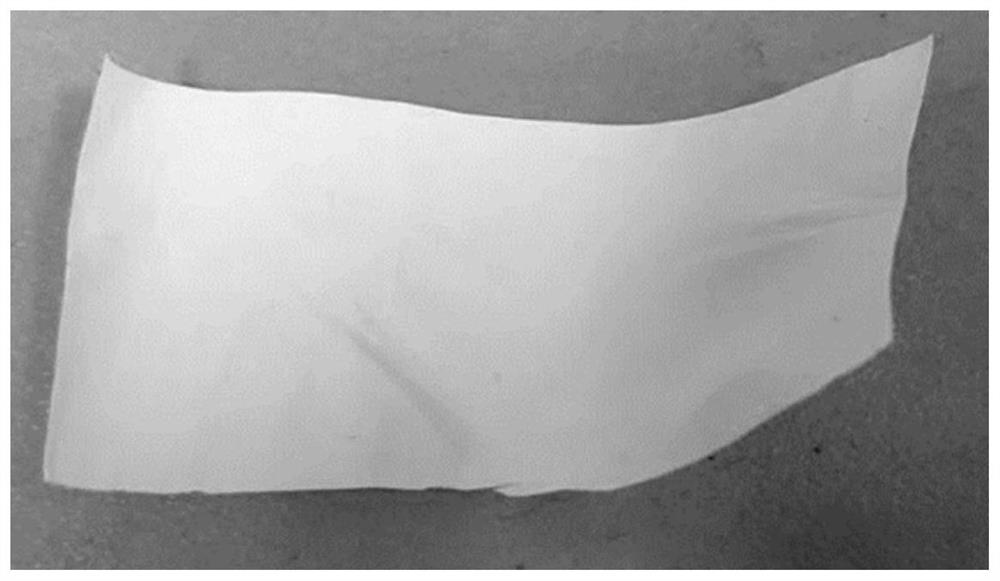

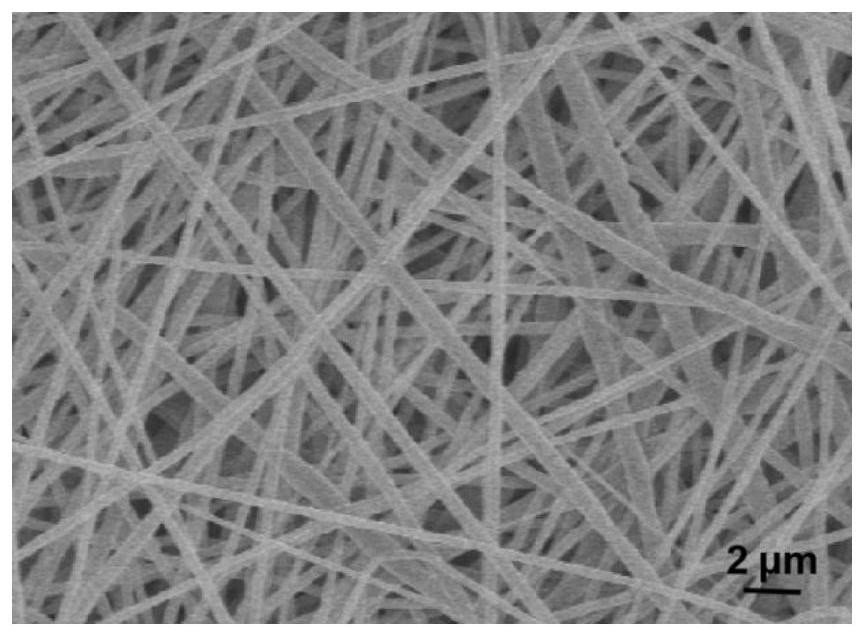

[0048] Example 1 Preparation of DFO-collagen blended artificial periosteum

[0049] Step 1. Dissolve 1.6g of medical grade type I collagen powder in 20mL of hexafluoroisopropanol, and stir magnetically at 37°C for 48 hours to fully dissolve to obtain a uniform collagen solution;

[0050] Step 2, adding DFO to the collagen solution obtained in Step 1, the amount added is 1% of the total mass of the solution, stirring evenly with a magnetic force at 37°C to obtain an electrospinning solution;

[0051] Step 3, electrospinning the solution obtained in step 2, using the stainless steel drum as the receiving device, the drum rotation rate is 600rpm, the spinning solution flow rate is 1.0mL / h, the voltage is 22kV, the receiving distance is 150mm, and the spinning time is 20h. An electrospun fiber membrane with a thickness of about 450 μm was obtained;

[0052] Step 4, placing the DFO-collagen blended fiber membrane obtained in step 3 at room temperature in a fume hood for 2 days to ...

Embodiment 2

[0057] Step 1: Dissolve 1.6g of gelatin powder in 20mL of acetic acid, stir magnetically at 37°C for 48 hours to fully dissolve to obtain a uniform gelatin solution;

[0058] Step 2, adding DFO to the gelatin solution obtained in step 1, the amount added is 0.6% of the total mass of the solution, stirring evenly with a magnetic force at 37°C to obtain an electrospinning solution;

[0059] Step 3, electrospinning the solution obtained in step 2, using the stainless steel drum as the receiving device, the drum rotation rate is 500rpm, the spinning solution flow rate is 3.0mL / h, the voltage is 15kV, the receiving distance is 200mm, and the spinning time is 8h. An electrospun fiber membrane with a thickness of about 200 μm is obtained;

[0060] Step 4, the DFO-gelatin blended electrospun fiber membrane obtained in step 3 is placed in a fume hood at room temperature for 3 days, and DFO is bonded to its surface with carbonyldiimidazole;

[0061] In step 5, the fibrous membrane obta...

Embodiment 3

[0063] Step 1, dissolving 1.6g of chitosan powder in 20mL of trifluoroethanol, stirring magnetically at 37°C for 48 hours to fully dissolve it to obtain a uniform chitosan solution;

[0064] Step 2, adding DFO to the chitosan solution obtained in step 1, the amount added is 0.8% of the total mass of the solution, and magnetically stirred at 37°C to obtain an electrospinning solution;

[0065] Step 3, electrospinning the solution obtained in step 2, using the stainless steel drum as the receiving device, the drum rotation rate is 300rpm, the spinning solution flow rate is 10mL / h, the voltage is 7kV, the receiving distance is 80mm, and the spinning time is 6h, and the obtained An electrospun fibrous membrane with a thickness of about 300 μm;

[0066] Step 4, place the DFO-chitosan blended electrospun fiber membrane obtained in step 3 at room temperature in a fume hood for 4 days, and use carbonyldiimidazole to bond DFO to its surface;

[0067] In step 5, the fiber membrane obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com