Preparation method and application of magnetic biomass charcoal material

A magnetic biochar and malachite green technology, applied in chemical instruments and methods, water pollutants, alkali metal compounds, etc., can solve the problems of low cost, MG exceeding the standard, etc., and achieve the effect of improving sensitivity and adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Weigh 1.0 g corn silk, 1.35 g FeCl 3 ·6H 2 O, 3.60 g of anhydrous sodium acetate, and 1.00 g of polyethylene glycol were dissolved in 40 mL of ethylene glycol, ultrasonicated for 30 min, transferred to a 50 mL hydrothermal reaction synthesis kettle, sealed and placed in an oven at 190 °C for 24 h. Cool to room temperature, wash with ultrapure water and absolute ethanol, and dry in vacuum at 60 °C for 8 h to obtain the black solid material MCH, then use potassium hydroxide at 700 °C under nitrogen protection conditions at a ratio of 1:2 (MCH:KOH) was activated for 2 h, and the obtained material was washed with hydrochloric acid, deionized water and absolute ethanol in sequence, and dried in a vacuum oven at 60 °C for 8 h to obtain the final product magnetic biochar material MPC.

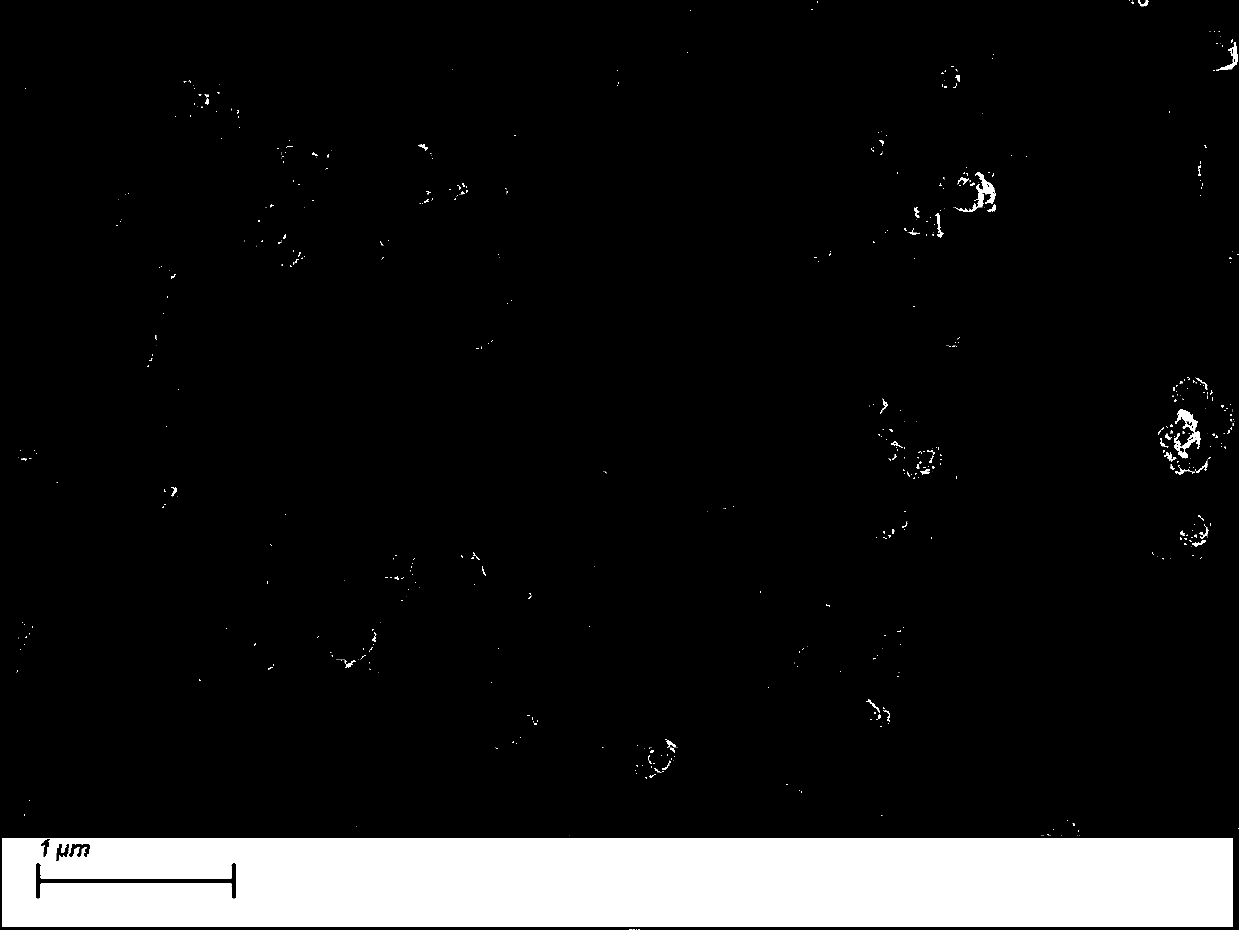

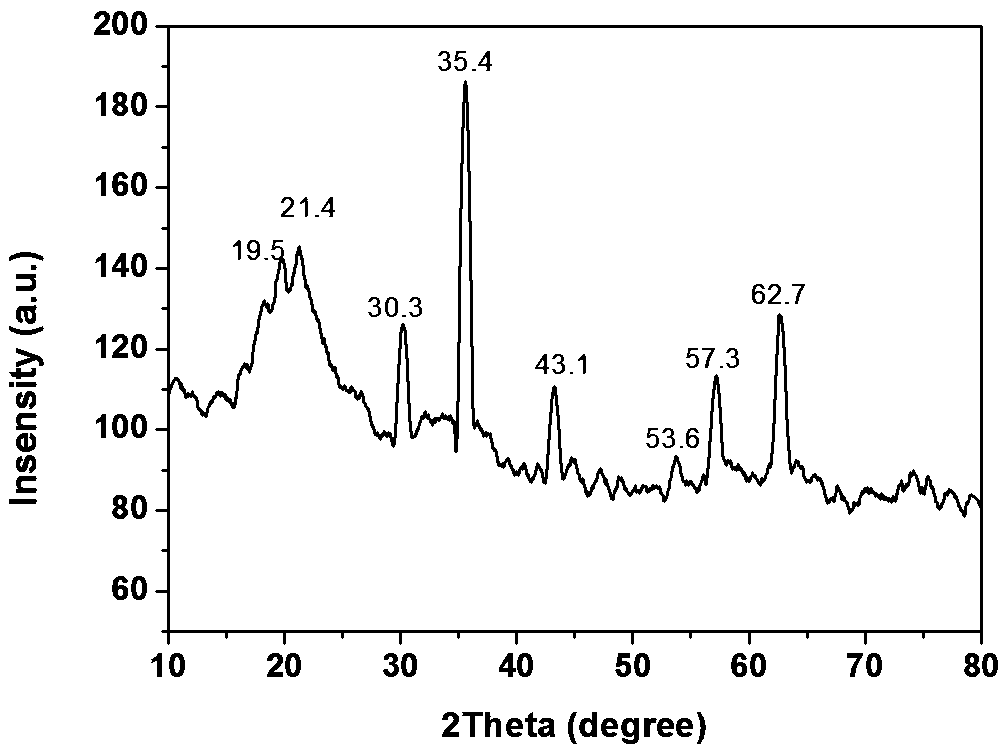

[0028] Below, the physical and chemical properties of the magnetic biomass carbon material MPC were characterized by scanning electron microscopy (SEM), X-ray diffraction (XRD) and other metho...

Embodiment 2

[0032] Weigh 1.0 g corn silk, 1.35 g FeCl 3 ·6H 2 O, 3.60 g of anhydrous sodium acetate, and 1.00 g of polyethylene glycol were dissolved in 40 mL of ethylene glycol, ultrasonicated for 30 min, transferred to a 50 mL hydrothermal reaction synthesis kettle, sealed and placed in an oven at 190 °C for 24 h. Cool to room temperature, wash with ultrapure water and absolute ethanol, and dry in vacuum at 60 °C for 8 h to obtain MCH as a black solid material, then use potassium hydroxide at 700 °C under the condition of nitrogen protection at a ratio of 1:1, 1 :2 and 1:3 ratio (MCH:KOH) for activation reaction for 2 h, the obtained material was washed with hydrochloric acid, deionized water and absolute ethanol in sequence, and dried in a vacuum oven at 60 °C for 8 h to obtain the final product Magnetic biomass carbon material MPC.

[0033] When MCH:KOH=1:1, MCH is not fully activated and the adsorption capacity is not good. When MCH:KOH=1:2, MCH is fully activated and the adsorptio...

Embodiment 3

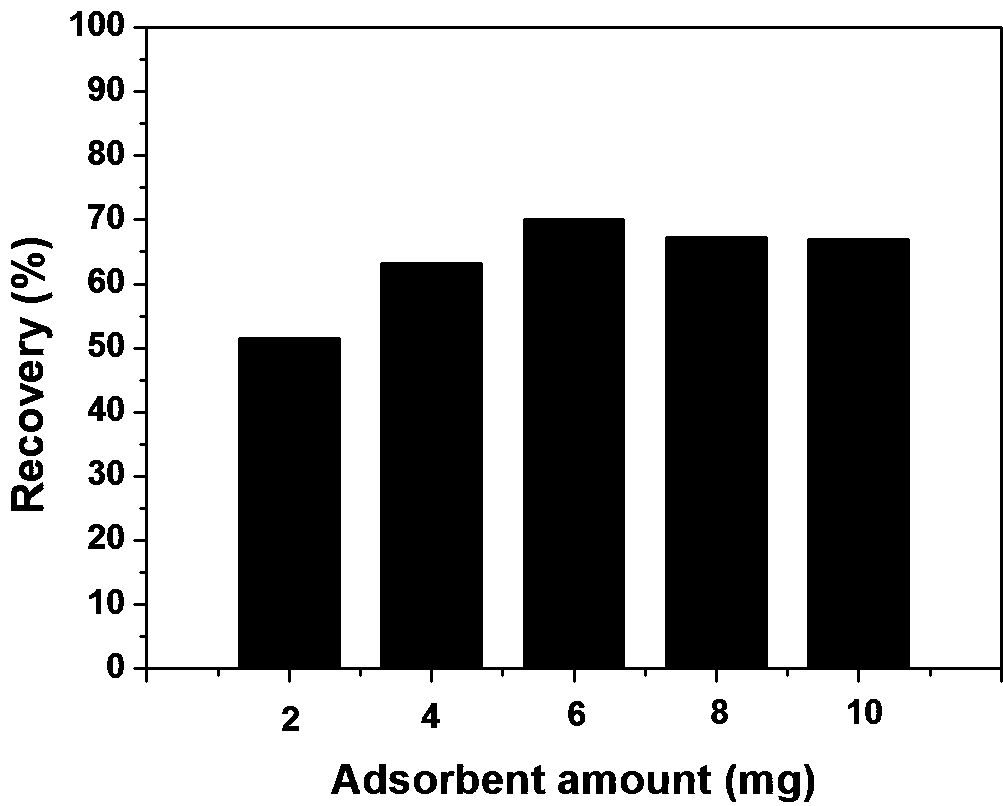

[0035] This embodiment provides a method for extracting trace MG in water using the magnetic biochar material MPC described in Embodiment 1, comprising the following steps:

[0036] Disperse 6 mg of the magnetic biochar material MPC in 10 mL of the water sample to be tested, vortex and shake for 20 min, so that MG is completely adsorbed on the magnetic biochar material MPC, then discard the supernatant, add 3 mL Eluate (methanol: acetic acid = 9:1 (v / v)), vortex again for 30 min for magnetic separation, take the supernatant, blow dry with nitrogen, and take 500 μL of this solution for UPLC analysis.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com