A kind of potassium titanyl phosphate thin film negative electrode material and its preparation method and application

A technology of potassium titanyl phosphate and negative electrode materials, which is applied in nanotechnology, chemical instruments and methods, phosphorus compounds, etc. for materials and surface science, and can solve the problem of reducing the mass fraction of active materials in electrodes, not suitable for battery fields, and high temperature Response to high energy consumption and other issues, to achieve the effect of facilitating the transmission of electrons, excellent cycle stability, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

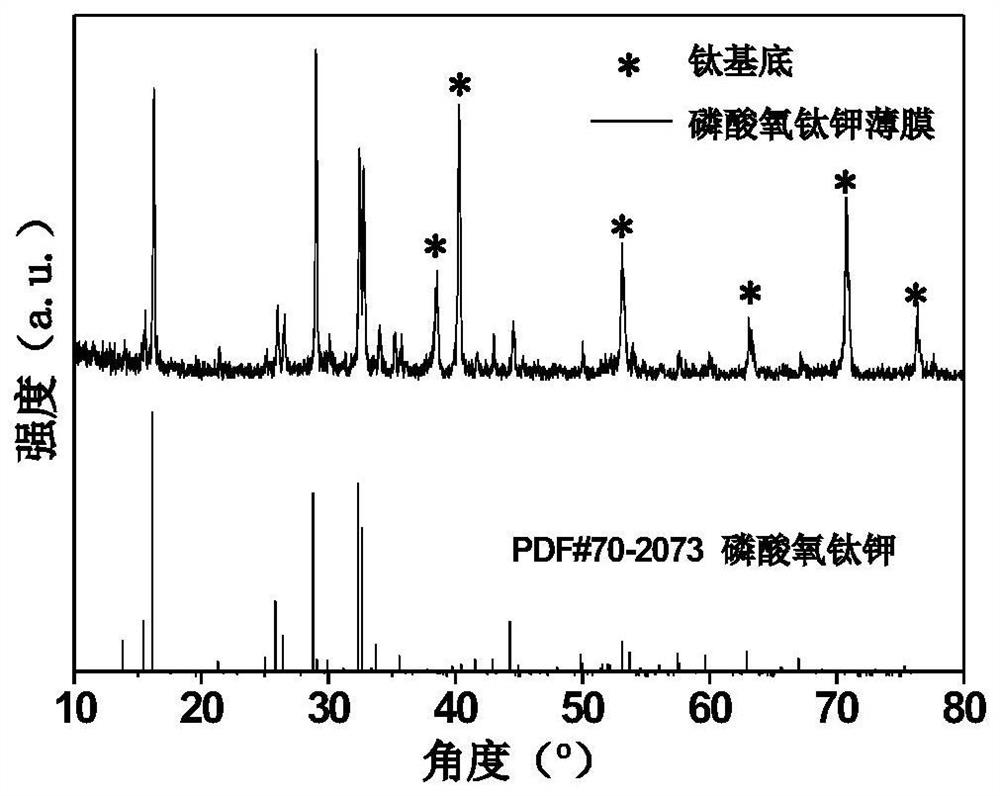

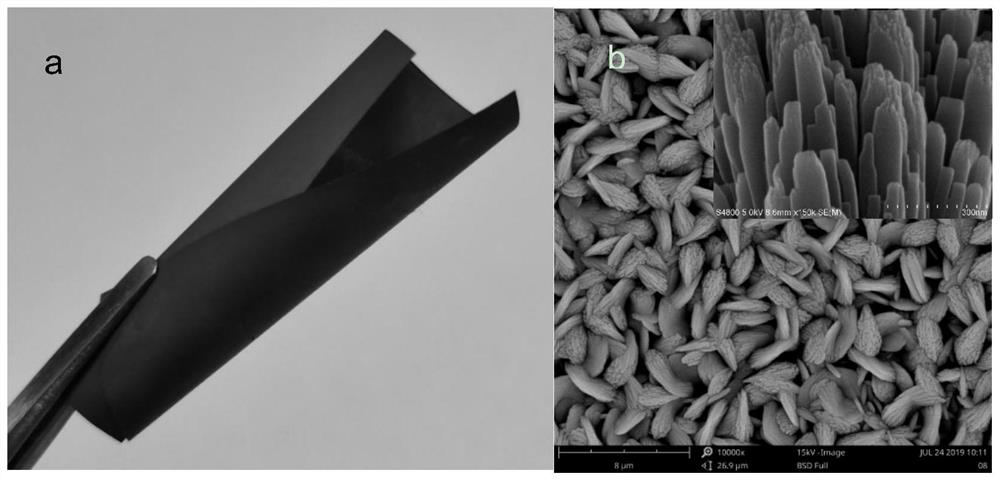

[0031] This example shows a preparation method of potassium titanyl phosphate thin film negative electrode material.

[0032] Potassium titanyl phosphate film is synthesized by a one-step hydrothermal method, including the following steps:

[0033] (1) 50μm 3.5*3.5cm 2 Polish the titanium sheet with 360-mesh sandpaper to clean the oxide layer on its surface; (2) ultrasonically clean it with hydrochloric acid, acetone and absolute ethanol for 15 minutes each; (3) mix potassium dihydrogen phosphate and deionized water evenly to obtain 2mol / L (4) place the titanium sheet and the above solution in an autoclave with a polytetrafluoroethylene liner substrate, and conduct a hydrothermal reaction at 220°C for 24 hours; (5) put the above step (4) after the hydrothermal reaction for a long The titanium sheet with the potassium titanyl phosphate film is taken out, rinsed with deionized water, and dried in an oven to finally prepare a binder-free potassium titanyl phosphate negative elec...

Embodiment 2

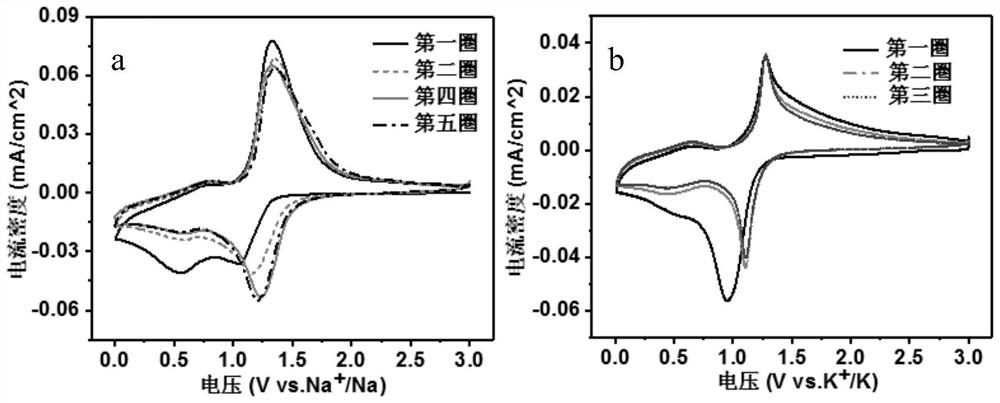

[0036] This example shows a sodium-ion battery in which a potassium titanyl phosphate film is used as the negative electrode of the binder-free sodium-ion battery.

[0037] The potassium titanyl phosphate thin film obtained in embodiment 1 is cut into 1*1cm 2 The square electrode sheet is used as the negative electrode material of the sodium ion battery, and the counter electrode and the reference electrode of the sodium ion battery are metallic sodium.

[0038] The formula of the electrolyte consists of: the solvent is Diglyme (diglyme); the electrolyte sodium salt is NaPF 6 , the concentration of the substance in the electrolyte is 1mol / L.

[0039] Assemble the above-mentioned potassium titanyl phosphate negative electrode sheet, electrolyte, sodium metal and others such as glass fiber diaphragm, stainless steel gasket, spring and battery casing into a 2032-type button battery.

[0040]Carry out cyclic voltammetry and constant current charge and discharge tests on the batt...

Embodiment 3

[0042] This example shows a potassium titanyl phosphate thin film used as the negative electrode of the binder-free potassium ion battery.

[0043] The potassium titanyl phosphate thin film obtained in embodiment 1 is cut into 1*1cm 2 The square electrode sheet is used as the negative electrode material of the potassium ion battery, and the counter electrode and the reference electrode of the potassium ion battery are metallic potassium.

[0044] The composition of the electrolyte is as follows: the solvent is EC (ethylene carbonate) / PC (propylene carbonate); the electrolyte potassium salt is KPF 6 , the concentration of the substance in the electrolyte is 1mol / L.

[0045] Assemble the above-mentioned potassium titanyl phosphate negative electrode sheet, electrolyte, metal potassium foil and others such as glass fiber diaphragm, stainless steel gasket, spring and battery casing into a 2032-type button battery.

[0046] Carry out cyclic voltammetry and constant current charge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com