Fluorine-containing polymer film, and preparation method and application thereof

A polymer film and polymer technology are applied in the field of fluorine-containing polymer films and their preparation, which can solve problems such as changes in film properties, difficulty in separating and reusing organic solvents, and achieve low pollution, good prospects for large-scale industrial production, mechanical Excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

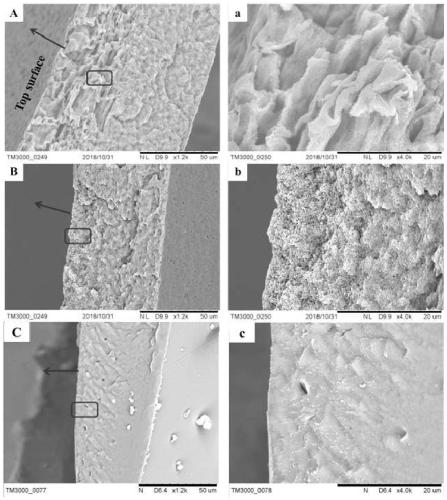

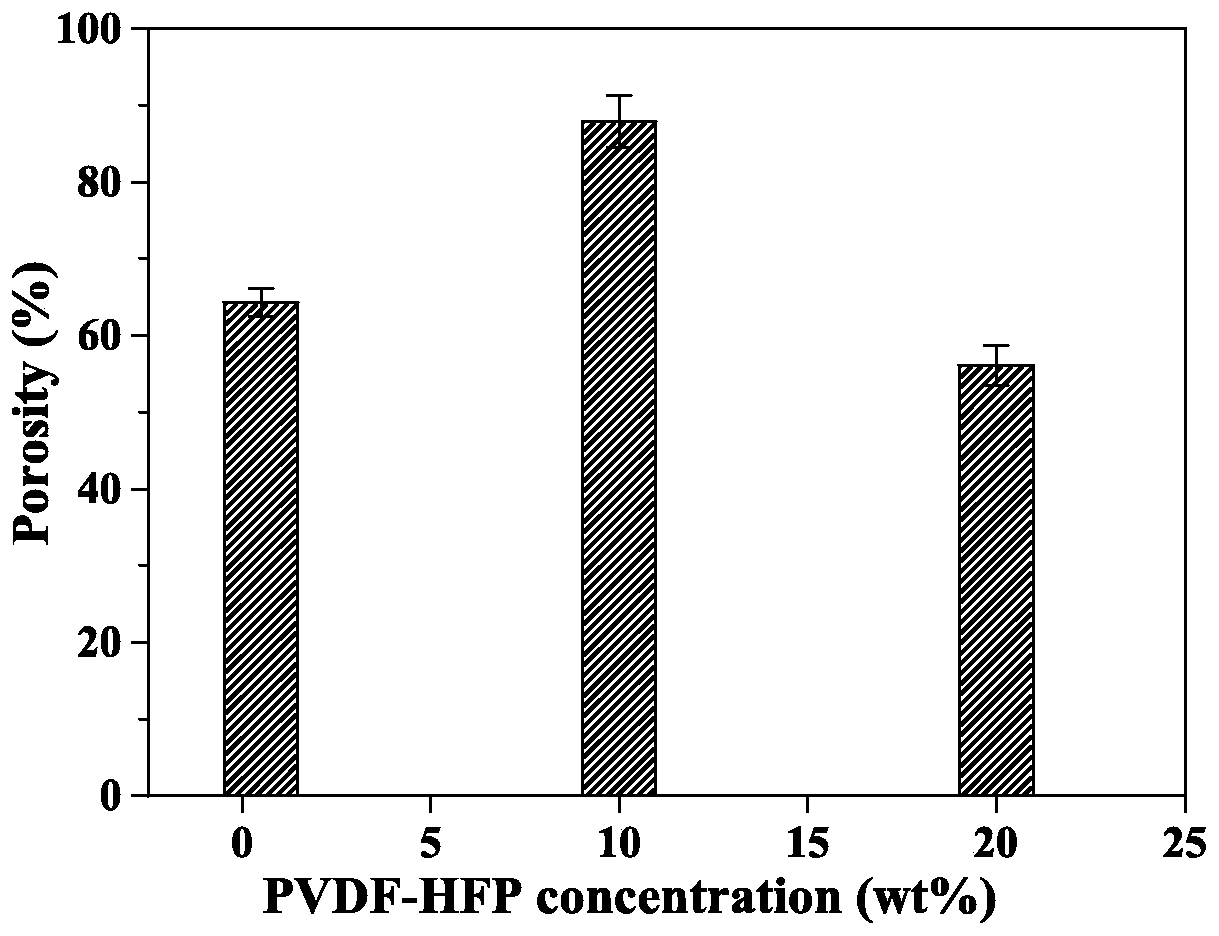

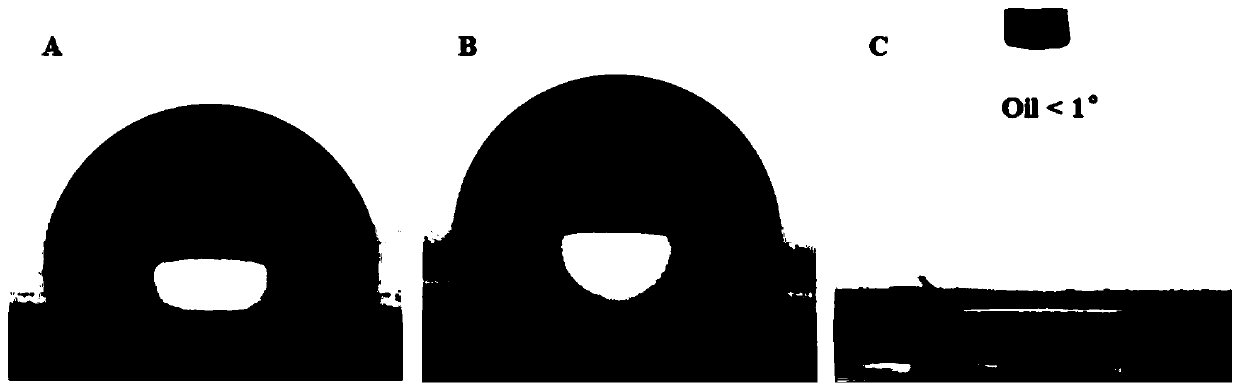

[0039] Add poly(vinylidene fluoride-hexafluoropropylene) copolymer and modification additive NMP in 15mL acetone solvent, the mass fraction of polymkeric substance in solution is respectively 0.5%, 10% and 20%, the mass fraction of NMP is 5% , After stirring for 24h, a homogeneous solution was formed for later use. Fill the bottom of the desiccator with ammonia water, put the tray and glass substrate into the desiccator, seal the desiccator for 24 hours, and put the desiccator in an oven to control the temperature at 20°C. After the liquid volatilizes, the atmosphere steam fills the entire desiccator. Cast the spare solution on a glass substrate in a closed desiccator (casting and casting into a solution layer with a thickness of 0.01-20 mm), and let it stand for 24 hours. During the standing process, as the solvent volatilizes, the surface temperature of the solution decreases, and the steam atmosphere, which is a poor solvent for fluoropolymers, condenses on the surface of t...

Embodiment 2

[0042] Add 750 mg of polyvinylidene fluoride to 15 mL of acetone solvent, stir for 24 hours to form a uniform solution for later use. The airtight container is filled with 50% / 50% and 20% / 80% ammonia-ethanol mixed atmosphere, and the temperature is controlled at -10°C. The above-mentioned standby solution was cast-cast on the glass substrate placed in the above-mentioned steam atmosphere (cast-cast to form a solution layer with a thickness of 0.01-20 mm), and stood still for 24 hours. During the standing process, as the acetone volatilizes, the surface temperature of the solution decreases, and ammonia vapor, which is a poor solvent for fluoropolymers, condenses on the surface of the solution, dehydrofluorination cross-linking and steam-induced phase separation occur. After the solvent is completely volatilized, it can be A polyvinylidene fluoride film with a white surface and various morphologies was prepared. Since the prepared film has interpenetrating porous structure and...

Embodiment 3

[0044] Add ethylene-tetrafluoroethylene copolymer and trimethyl phosphate to 15 mL of tetrahydrofuran solvent, the mass fraction of both in the solution is 5%, and stir for 24 hours to form a uniform solution for later use. The airtight container is filled with a mixed atmosphere of methanol and ethanol, the content of methanol is controlled at 20-80%, and the temperature is controlled at 30°C. The above-mentioned standby solution was cast-cast on the glass substrate placed in the above-mentioned steam atmosphere (cast-cast to form a solution layer with a thickness of 0.01-20 mm), and stood still for 24 hours. During the standing process, the surface temperature of the solution decreases with the volatilization of tetrahydrofuran, and ammonia water vapor, which is a poor solvent for fluoropolymers, condenses on the surface of the solution, and a steam-induced phase separation process occurs. After the solvent is completely volatilized, the following Figure 5 Surface white pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com