Eggshell-yolk structured cobaltosic oxide-nitrogen doped carbon/carbon nanocage composite material and preparation method and application thereof

A nanocomposite material, cobalt tetroxide technology, applied in nanotechnology, nanotechnology, nanotechnology and other directions for materials and surface science, can solve the problems of volume expansion and contraction effects, poor material cycle stability, low rate capacity, etc. Increased storage sites, significant confinement effect, and improved conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The preparation of embodiment 1 carbon nanocage

[0038]The first is the preparation process of carbon nanocages: add 600ml of absolute ethanol, 80ml of water, and 24ml of ammonia (25wt%) into a 1000ml round-bottomed flask, and after stirring for 5min to form a uniform mixed solution, 27.68ml of tetraethyl silicate The ester was added dropwise into the mixed solution, and after 5 min was added, the stirring was continued for 15 min, then 3.2 g of resorcinol was added, and then 4.48 ml of formaldehyde solution (37 wt %) was added dropwise to the above solution, and after stirring at room temperature for 24 h, Centrifuge, wash, dry, and place the obtained powder in a tube furnace for sintering (sintering conditions: under nitrogen atmosphere, heating rate 2°C / min, sintering at 700°C for 5h), and finally put the sintered product at 80°C, 500ml , etched in 1mol / L sodium hydroxide solution for 2h, filtered with suction, washed, and dried to obtain carbon nanocages.

Embodiment 2

[0039] Example 2 Preparation of cobalt tetroxide-nitrogen-doped carbon / carbon nanocage composite material of eggshell-egg yolk structure

[0040] The method of simple co-precipitation combined with high-temperature calcination realizes the limited growth of cobalt tetroxide. The preparation process is:

[0041] Weigh 0.12g of the carbon nanocage powder prepared in Example 1 and 0.582g of cobalt acetate tetrahydrate and disperse them in 30ml of methanol solution, stir for 4h to form solution A;

[0042] Weigh 0.656g of 2-methylimidazole and disperse in 30ml of methanol solution, stir for 4h to form solution B.

[0043] Solution B was added dropwise into solution A, stirred and reacted at room temperature for 24 h, centrifuged, washed with water and ethanol 3 times, and dried to obtain precursor powder ZIF-67 / carbon nanocage composite (ZIF-67@CNC).

[0044] The dried precursor powder was calcined in a tube furnace at high temperature, and sintered at 550 °C for 2 h at a heating...

experiment example

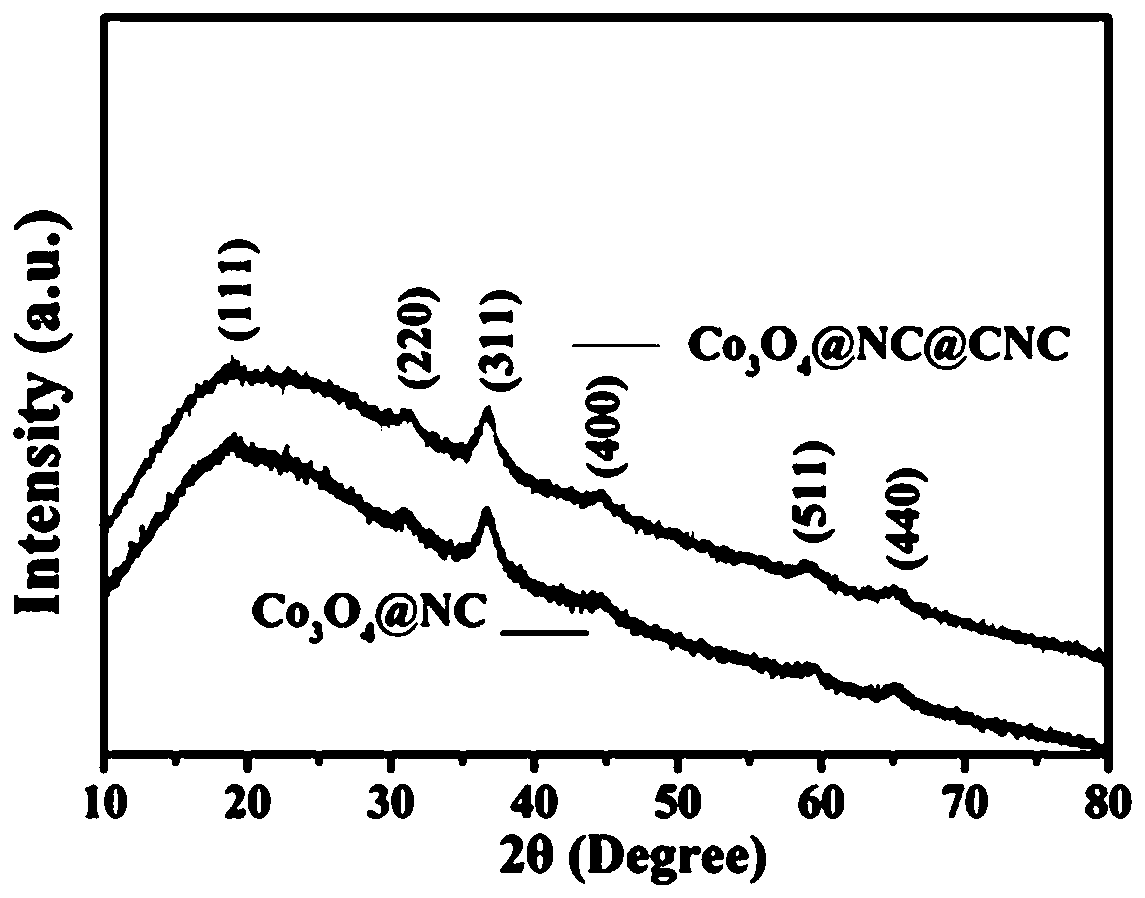

[0050] figure 1 It is the XRD pattern of the cobalt tetroxide-nitrogen-doped carbon prepared in Comparative Example 1 and the cobalt tetroxide-nitrogen-doped carbon / carbon nanocage composite material prepared in Example 2. From figure 1 It can be seen from the XRD patterns of the two materials that the peaks on the XRD patterns of the two materials correspond to the peaks of tricobalt tetroxide, indicating that after the two-step calcination, the free-growing ZIF-67 and the confined-growing ZIF-67@CNC were successfully transformed into into tricobalt tetroxide-nitrogen-doped carbon and tricobalt tetroxide-nitrogen-doped carbon / carbon nanocage composites.

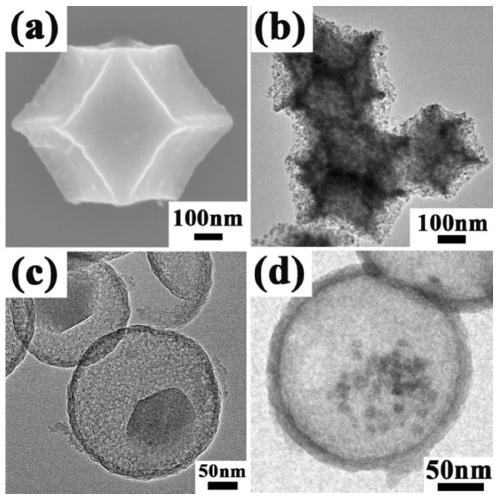

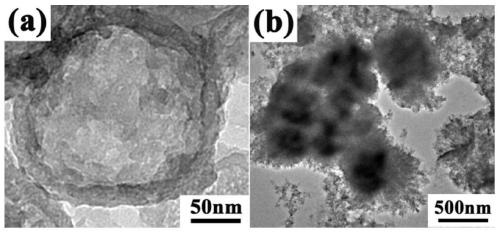

[0051] The precursor powder ZIF-67 prepared in comparative example 1, the tricobalt tetroxide-nitrogen-doped carbon material prepared in comparative example 1, the precursor powder ZIF-67 / carbon nanocage composite material prepared in embodiment 2 and the tricobalt tetroxide prepared in embodiment 2 - Nitrogen-doped carbon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com