Flaky MoS2-x coated hollow porous carbon sphere@sulfur composite material and preparation and application thereof

A technology of mos2-x and composite materials, applied in electrical components, battery electrodes, non-aqueous electrolyte batteries, etc., can solve the problems of low retention rate, lack of physical restrictions, uneven distribution of sulfur, etc., and achieve good electronic conductivity, The effect of uniform material appearance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Preparation of hollow porous carbon spheres is the same as the comparative example;

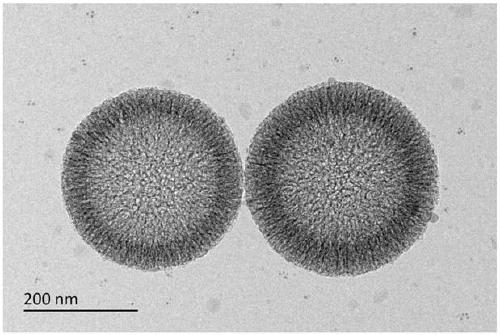

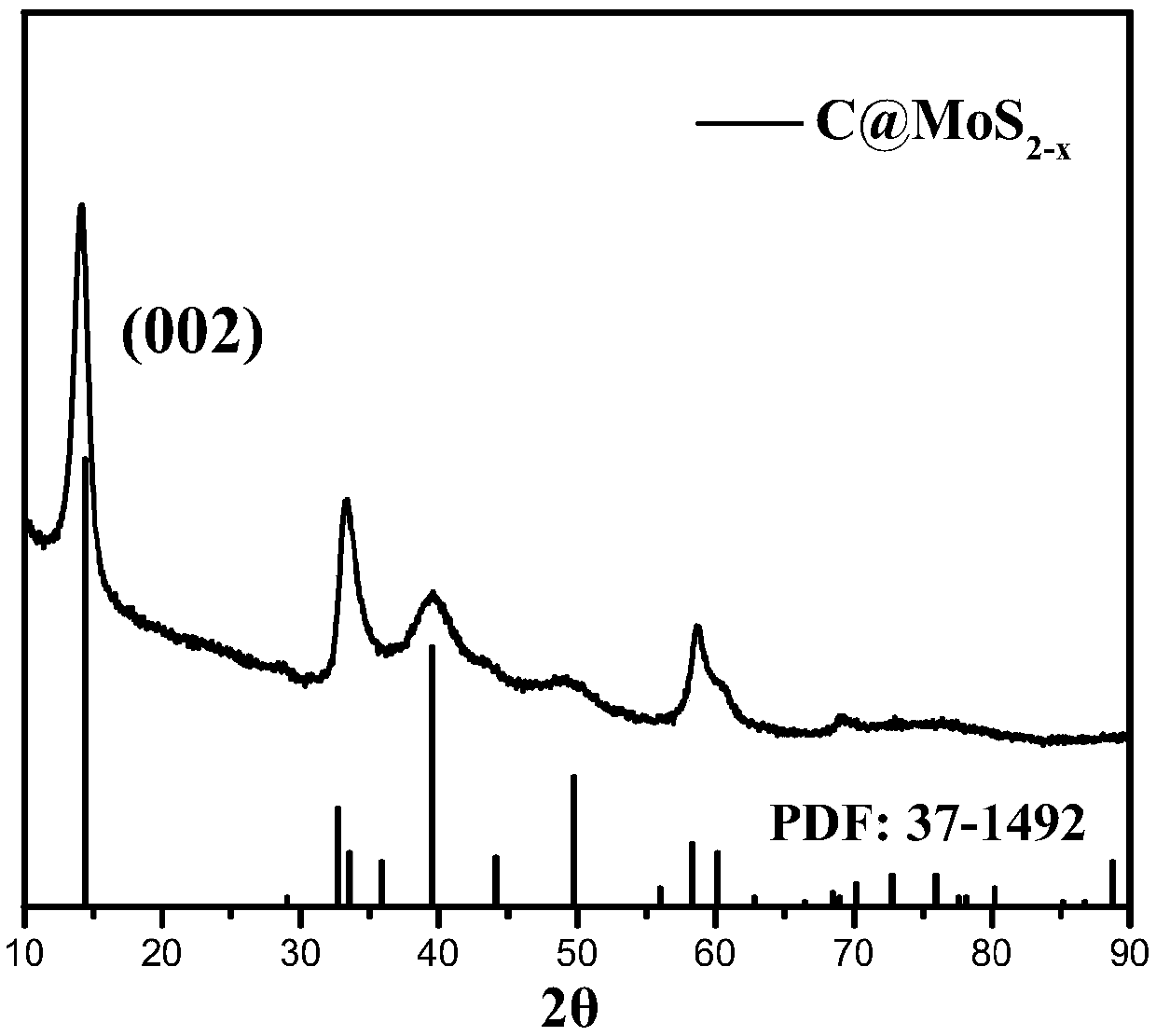

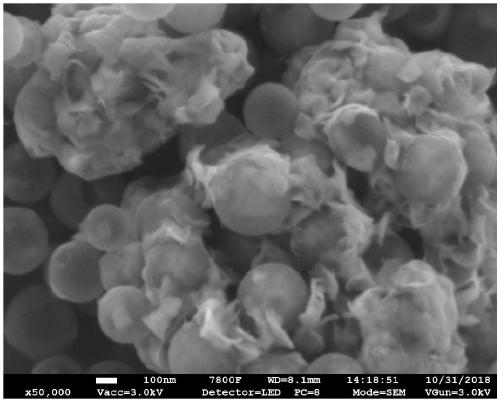

[0038] Take 0.03g of hollow carbon material, ultrasonically disperse it into 30ml of deionized water, add 0.180g of sodium molybdate and 1.8g of cysteine, stir evenly, transfer to a 50ml hydrothermal kettle, react at 180°C for 24h, take it out after cooling, and pump Filtration, washing, and drying, the resulting product was placed in a tube furnace, and treated in a 10% hydrogen-argon gas mixture at 700 ° C for 2 hours to obtain a sheet-shaped molybdenum disulfide-coated hollow porous carbon sphere material, and its XRD powder diffraction pattern is as follows figure 2 The scanning electron microscope image is shown in image 3 The transmission electron microscope image is shown in Figure 4 shown.

[0039] Take 0.1g of the prepared carbon@MoS 2-x , ground with 0.3 g of sublimed sulfur, transferred to a sealed reactor, and heat-treated at 155 °C for 12 h to obtain flake MoS 2-x C...

Embodiment 2

[0046] Add 10ml deionized water in the round bottom flask, 70ml ethanol and 3ml ammoniacal liquor (25wt%), after stirring, add 3.46ml tetraethyl orthosilicate quickly, add 0.2g resorcinol and 0.28ml formaldehyde solution ( 37wt%), reacted at room temperature for 24h, centrifuged, washed and dried the reaction solution to obtain brown silica@phenolic resin particles;

[0047] Carbonization process, etching process, MoS 2-x The coating process, the sulfur composite process and the coating of the subsequent pole piece and the assembly test of the battery are the same as in Example 1. The carbon content in the composite material is 7.5%, and the MoS 2-x The content of sulfur is 22.5%, the content of sulfur is 70%, the value of sulfur defect x is 0.05, the inner diameter of the hollow carbon sphere cavity is 300nm, the thickness of the carbon layer is 20nm, and the specific surface area is 852m 2 g -1 , the pore volume is 1.845cm 3 g -1 ;

[0048] For the obtained hollow carbo...

Embodiment 3

[0050] Add 10ml deionized water in the round bottom flask, 70ml ethanol and 3ml ammoniacal liquor (25wt%), after stirring, add 3.46ml tetraethyl orthosilicate quickly, add 0.6g resorcinol and 0.84ml formaldehyde solution ( 37wt%), reacted at room temperature for 24h, centrifuged, washed and dried the reaction solution to obtain brown silica@phenolic resin particles;

[0051] Carbonization process, etching process, MoS 2-x The coating process, the sulfur composite process and the coating of the subsequent pole piece and the assembly test of the battery are the same as in Example 1. The carbon content in the composite material is 22.9%, and the MoS 2-x The content of sulfur is 8.4%, the content of sulfur is 68.7%, the value of sulfur defect x is 0.05, the inner diameter of the hollow carbon sphere cavity is 300nm, the thickness of the carbon layer is 75nm, and the specific surface area is 1487m 2 g -1 , the pore volume is 1.566cm 3 g -1 ;

[0052] For the obtained hollow ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| mesopore | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com