Phenylboronic acid modified metal organic framework composite fiber and preparation method and application thereof

A metal-organic framework and composite fiber technology, applied in synthetic fibers, alkali metal compounds, animal fibers, etc., can solve the problems of limited specific surface area of nanomaterials and polymers, limited immobilization of boronic acid groups, etc., and achieve adjustable pore size. and surface modification properties, good flexibility, mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

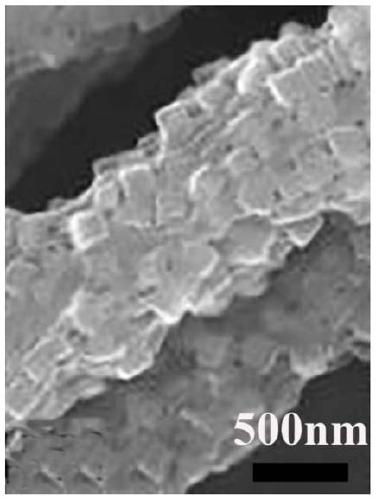

[0068] (a) Preparation and surface functionalization of CoCu-based MOF materials

[0069] ① Preparation of CoCu-MOF: Dissolve 0.83 g of 2-methylimidazole in 40 mL of methanol, and add the solution to 40 mL of 0.181 g of cobalt nitrate, 0.151 g of copper nitrate and 0.36 g of sodium lauryl sulfate under stirring at room temperature. In the methanol solvent, after 20 hours of reaction, the CoCu-MOF obtained by centrifugation, washing, drying and collection;

[0070] ② Weigh 100mg of CoCu-MOF sample and dissolve it in 100mL of ethylene glycol, blow nitrogen gas to remove oxygen, and use an ultrasonic cleaner to disperse evenly; ③ Measure 2ml of aminoethyltripropoxysilane reagent containing amino functional groups and dissolve Alcohol and added into the ② solution, functionalized self-assembly of the CoCu-MOF surface, fully washed with absolute ethanol, the CoCu bimetallic MOF material modified with alkoxysilane reagent containing functional groups was obtained.

[0071] (b) Prep...

Embodiment 2

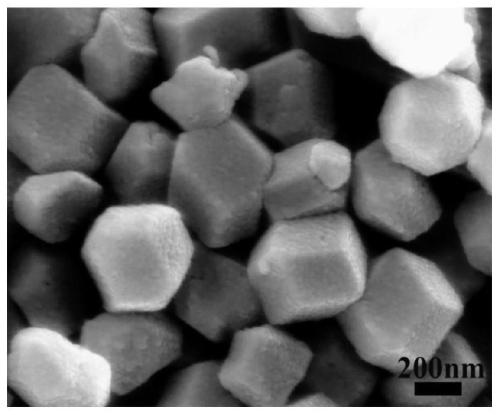

[0078] (a) Preparation and surface functionalization of MnZn-based MOF materials

[0079] ① Preparation of MnZn-MOF: Dissolve 1.18 g of benzimidazole in a mixed solvent of 40 mL of DMF and water (volume ratio 5:3), and add the solution to 40 mL of 0.062 g of manganese nitrate and 0.223 g of nitric acid under stirring at room temperature. In a mixed solvent of zinc and 0.42 g of polypropyleneimine in DMF and water (volume ratio 5:3), after hydrothermal reaction at 150°C for 20 hours, the MnZn-MOF obtained by centrifugation, washing, drying, and collection;

[0080] ② Weigh 200 mg of MnZn-MOF sample and dissolve it in 100 ml of isopropanol, blow nitrogen gas to remove oxygen, and use an ultrasonic cleaner to disperse evenly; ③ Measure 3 ml of aminoethyltrimethoxysilane reagent containing amino functional groups and dissolve it in isopropanol Alcohol and added into the ② solution, the surface of MnZn-MOF was functionalized and self-assembled, and fully washed with absolute ethano...

Embodiment 3

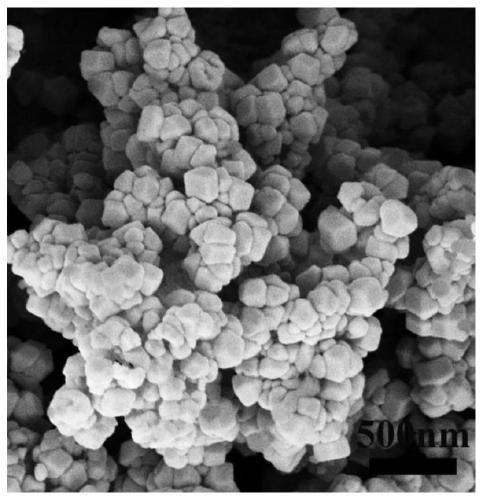

[0088] (a) Preparation and surface functionalization of CoZn-based MOF materials

[0089] ① Preparation of CoZn-MOF: Dissolve 1.983 g of 2,5-dihydroxyterephthalic acid in a mixed solvent of 40 mL of DMF, ethanol and water (volume ratio 1:1:1), and add the solution to Into 40mL mixed solvent containing DMF, ethanol and water (volume ratio 1:1:1) of 0.161 gram of cobalt nitrate, 0.165 gram of zinc nitrate and 1.304 gram of polyvinyl alcohol, after hydrothermal reaction at 200 ℃ for 15 hours, by centrifugation, Cleaning, drying, and collecting the obtained CoZn-MOF;

[0090] ② Weigh 300 mg of CoZn-MOF sample and dissolve it in 100 ml of pentylene glycol, blow nitrogen gas to remove oxygen, and use an ultrasonic cleaner to disperse evenly; ③ Measure 4 ml of aminopropyl tripropropoxysilane reagent containing amino functional groups and dissolve Diol and added into the ② solution, the CoZn-MOF surface is functionalized and self-assembled, and the CoZn-MOF surface is fully washed wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com