Biogas slurry concentrated solution compound fertilizer and method for cultivating vegetables by using same

A concentrated liquid and compound fertilizer technology, applied in fertilization methods, liquid fertilizers, applications, etc., can solve problems such as endangering human health and exceeding standards, and achieve the effects of stable changes in heavy metal content, reducing membrane pollution, and excellent recycling value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Embodiment 1 Preparation of biogas slurry concentrated fertilizer (or biogas slurry concentrated liquid compound fertilizer) of the present invention

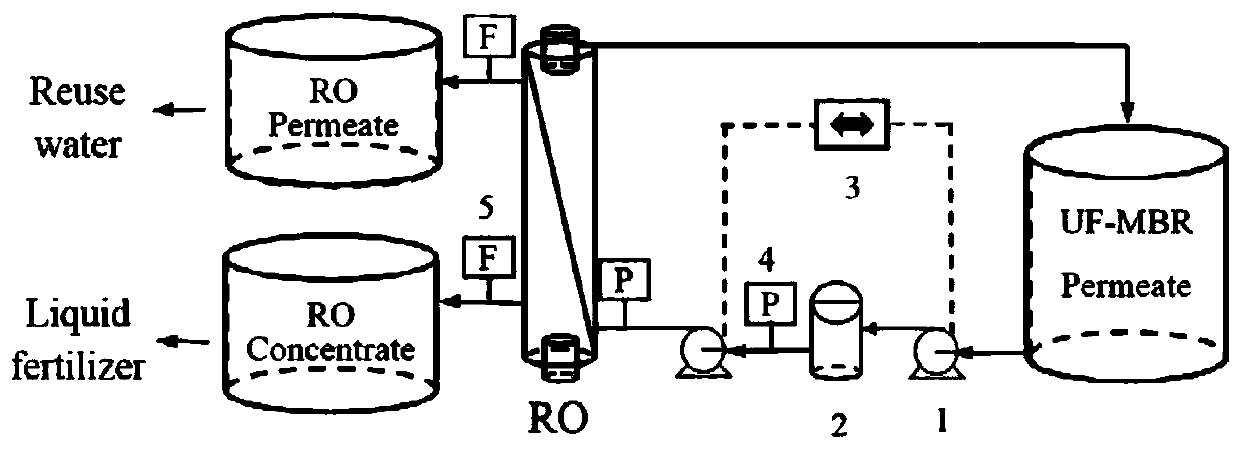

[0069] Step 1: Preparation of Biogas Slurry Membrane Concentrate

[0070] 1.1 Biogas slurry treatment by ultrafiltration-membrane bioreactor (UF-MBR)

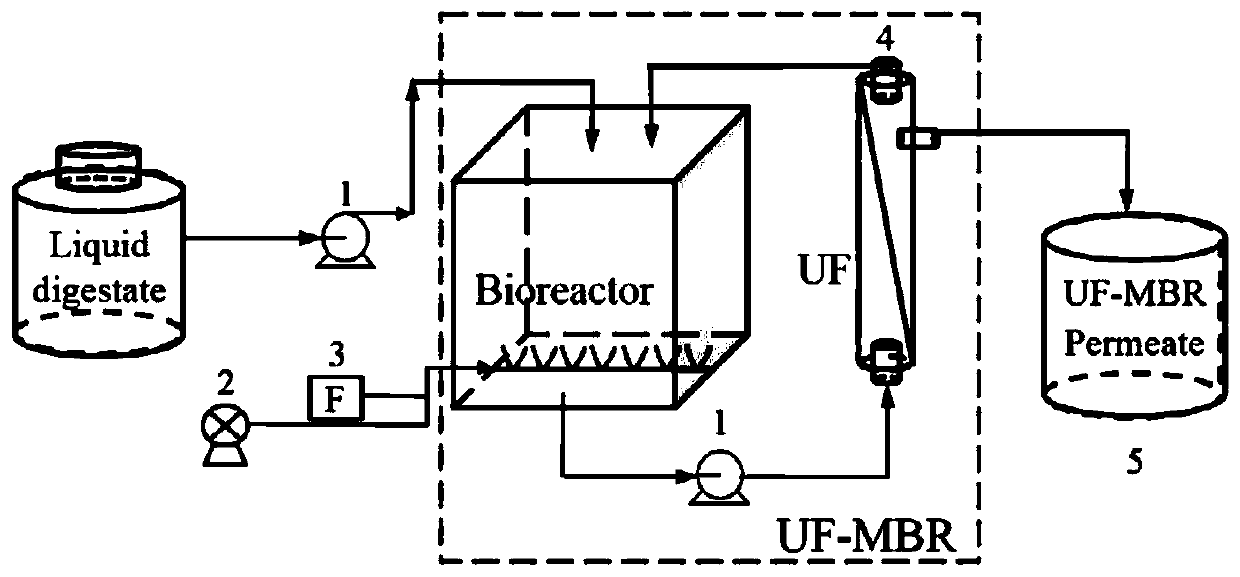

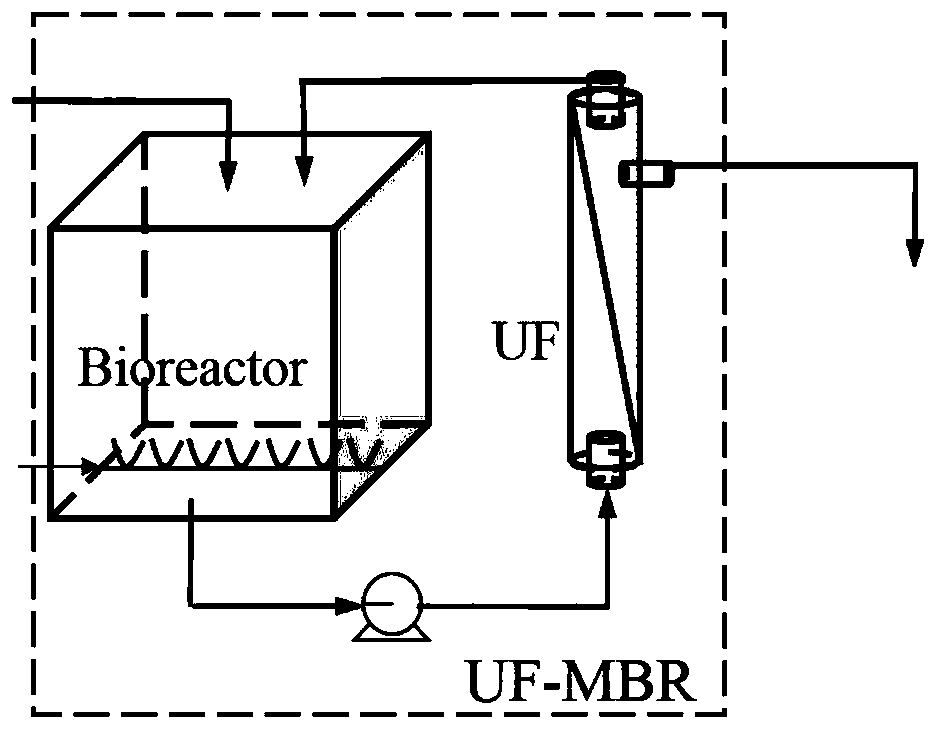

[0071] Ultrafiltration-membrane bioreactor (structure such as figure 2 shown) consists of an aerobic bioreactor and an ultrafiltration membrane, and the treatment method is as follows:

[0072] (1) Aerobic activated sludge treatment: refer to figure 1 As shown in the flowchart, 2.0L pig farm biogas slurry is sent to the ultrafiltration-membrane bioreactor (UF-MBR), first passed through the aerobic bioreactor (Bioreactor), and the biogas is treated in the presence of 2.0L aerobic activated sludge The treatment parameters are set as follows: sludge inoculum size (MLSS) is 12g / L, hydraulic retention time (HRT) is 2 days, dissolved oxygen (DO) concentration is controlled ...

experiment example 1

[0085] Dissolved Oxygen (DO) Concentration Screening in Experimental Example 1 Aerobic Activated Sludge Process of the present invention

[0086] 1. Experimental method

[0087] With reference to the aerobic activated sludge treatment method of the first step (1) of Example 1, 2.0L of pig farm biogas slurry is sent into an aerobic bioreactor, and 2.0L of aerobic activated sludge is used to treat the biogas slurry to control sludge The inoculum size (MLSS) is 12g / L, the hydraulic retention time (HRT) is 2 days, the aeration rate is 0.6-1.6L / min, and only the dissolved oxygen concentration is changed so that the dissolved oxygen concentration is 1.0, 2.0, 3.0, 4.0 respectively and 5.0mg / L. Then the pH and chemical oxygen demand (COD), total nitrogen (TN), organic carbon (TOC), total phosphorus (TP), electrical conductivity, salinity and total soluble solids (TDS) of the effluent were measured under different dissolved oxygen concentrations. Suspended solids (SS), trace element...

experiment example 2

[0104] Experimental Example 2 The Influence of Ultrafiltration Membrane on Physicochemical Properties of Biogas Slurry in Ultrafiltration-Membrane Bioreactor (UF-MBR) of the present invention

[0105] 1. Experimental method

[0106] Get respectively the effluent (i.e. the influent in table 3) after the first step of embodiment 1 step (1) aerobic activated sludge treatment, step (2) the effluent after the ultrafiltration membrane separation (i.e. the permeation in table 3) liquid) to carry out the physical and chemical property test, each index test method is as described in Experimental Example 1.

[0107] 2. Experimental results

[0108] 2.1 Effect of ultrafiltration membrane in ultrafiltration-membrane bioreactor on suspended solids and turbidity of biogas slurry

[0109] The results are shown in Table 3. It can be seen that UF can effectively separate most SS and colloidal substances, so as to ensure that the UF-MBR effluent biogas slurry has a low concentration of SS an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com