A high-performance self-cleaning epoxy resin coating and its preparation method

An epoxy resin coating, epoxy resin technology, applied in epoxy resin coatings, coatings, antifouling/underwater coatings, etc., can solve problems such as difficulty in resisting marine microorganisms, cumbersome preparation methods, and high brittleness of coatings. problem, to achieve the effect of strengthening anti-wear and anti-wear, extensive antibacterial effect, and low surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

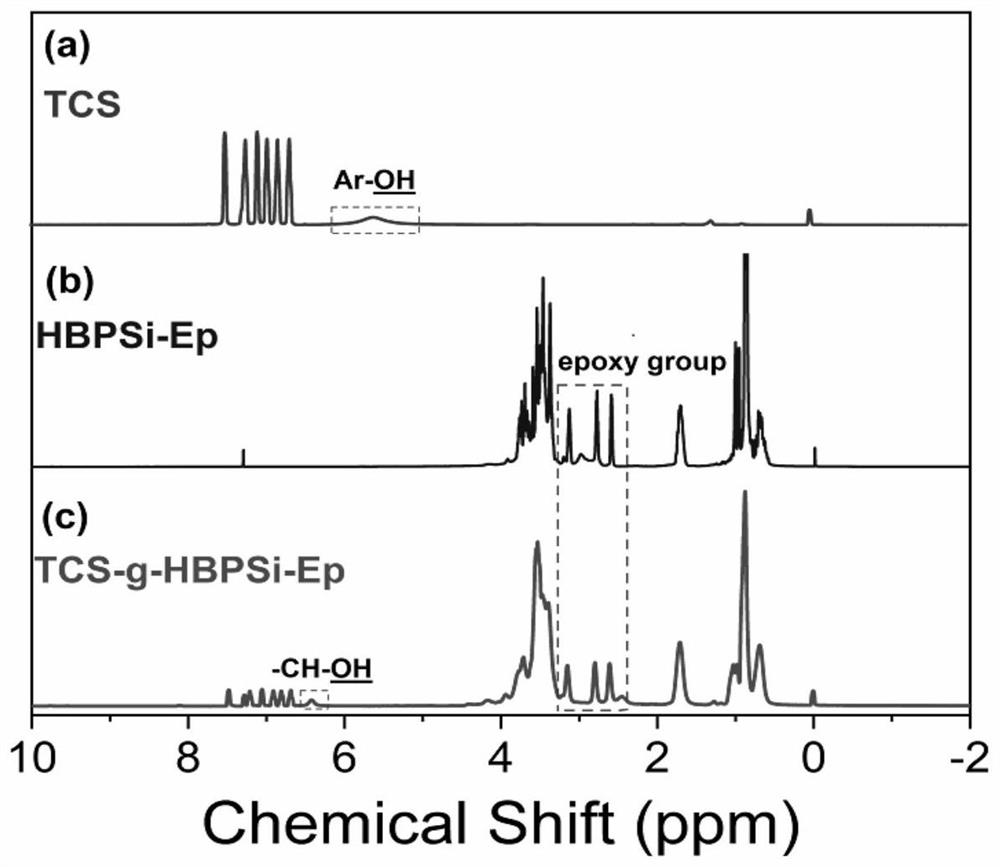

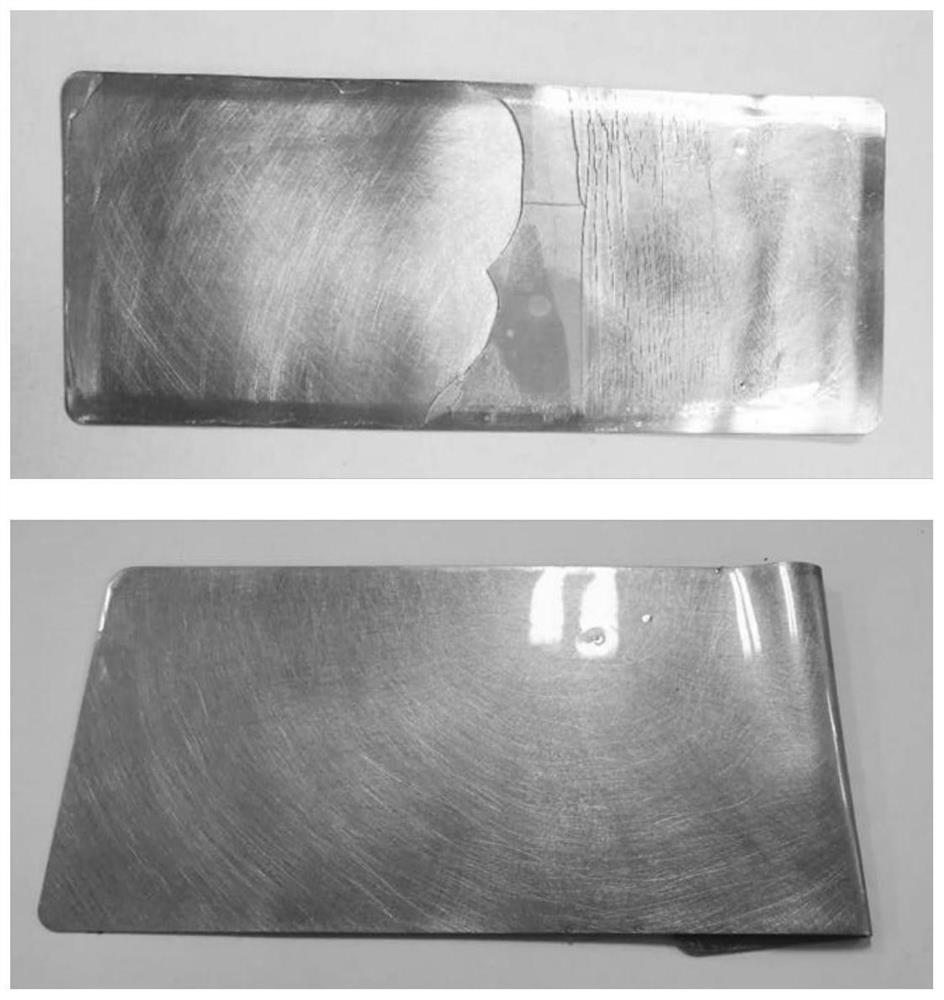

[0042] First, add 3-glycidyl etheroxypropyl trimethoxysilane and neopentyl glycol into a three-necked flask at a molar ratio of 1:1, and react under nitrogen protection, and the reaction temperature is controlled between 120 and 160°C , until no more distillate was formed. After that, add triclosan and hyperbranched polysiloxane into the three-necked flask at a mass ratio of 1:10, pass nitrogen, control the temperature at 120-150°C, and the reaction time is 6 hours. The reaction product is triclosan-grafted hyperbranched polysiloxane.

[0043] After that, prepare epoxy coating slurry: take 10g E-51 resin, 8g methyltetrahydrophthalic anhydride and 0.1g DMP-30, add 2g TCS-g-HBPSi, stir well and add 20ml N,N-dimethyl Diethyl acetamide (DMAC) was used to adjust the epoxy coating slurry to a suitable viscosity. Then pour the prepared slurry into the spray gun, adjust the airflow size of the spray gun and the size of the nozzle to the appropriate flow rate. Then use a spray gun t...

Embodiment 2

[0046] First, add 3-glycidyloxypropyltrimethoxysilane and 1,3-propanediol into a three-necked flask at a molar ratio of 1:1, and react under nitrogen protection, and the reaction temperature is controlled between 110 and 150°C time until no more distillate was formed. Afterwards, add triclosan and hyperbranched polysiloxane into a three-necked flask with a mass ratio of 1:8, pass nitrogen, control the temperature at 120-150°C, and the reaction time is 6 hours. The reaction product is triclosan-grafted hyperbranched polysiloxane.

[0047] Afterwards, prepare the slurry of epoxy coating: get 10g E-51 resin and 3.3g DDS, add 1.67g TCS-g-HBPSi, add 20ml N after stirring evenly, N-dimethylacetamide (DMAC), will The epoxy coating slurry is adjusted to a suitable viscosity. Then pour the prepared slurry into the spray gun, adjust the airflow size of the spray gun and the size of the nozzle to the appropriate flow rate. Then use a spray gun to evenly spray the epoxy coating slurry ...

Embodiment 3

[0050] First, add 3-glycidyl etheroxypropyl trimethoxysilane and diethylene glycol into a three-necked flask at a molar ratio of 1:1, and react under nitrogen protection, and the reaction temperature is controlled at 110-160°C between until no more distillate was formed. After that, add triclosan and hyperbranched polysiloxane into the three-necked flask at a mass ratio of 1:10, pass nitrogen, control the temperature at 120-150°C, and the reaction time is 6 hours. The reaction product is triclosan-grafted hyperbranched polysiloxane.

[0051] After that, prepare epoxy coating slurry: take 10g E-44 resin, 6g methyltetrahydrophthalic anhydride and 0.1g DMP-30, add 1.5g TCS-g-HBPSi, stir well and add 15ml N,N-di Methylformamide (DMF), to adjust the epoxy coating slurry to a suitable viscosity. Then pour the prepared slurry into the spray gun, adjust the airflow size of the spray gun and the size of the nozzle to the appropriate flow rate. Then use a spray gun to evenly spray th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com