Medical packaging film and preparation method thereof

A packaging film and film layer technology, which is applied in the field of materials, can solve the problems of medical articles such as impact damage, unfavorable reuse, poor durability of ice packs, etc., and achieve the effects of high reuse rate, long-lasting cold storage effect, and excellent barrier performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

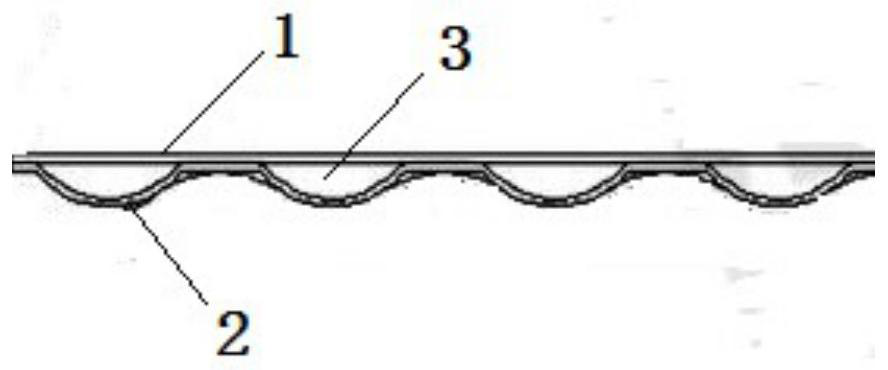

Image

Examples

preparation example Construction

[0028] In the embodiment of the present invention, the preparation method of the starch-based water-absorbent resin includes the following steps:

[0029] Add a mixed solution of sodium hydroxide and potassium hydroxide dropwise in acrylic acid until the pH is 4-6 to obtain a spare solution;

[0030] Add gelatinized starch and initiator into the standby solution, the mass ratio of the standby solution, gelatinized starch and initiator is 35-70:40-60:1, stir and heat under nitrogen atmosphere to carry out graft copolymerization Reaction, drying that is.

[0031] In the embodiment of the present invention, the mixed solution of sodium hydroxide and potassium hydroxide is prepared in equal amounts from a sodium hydroxide solution with a mass fraction of 25% and a potassium hydroxide solution with a mass fraction of 25%.

[0032] In the embodiment of the present invention, the gelatinized starch is obtained by stirring and gelatinizing cornstarch and an appropriate amount of wate...

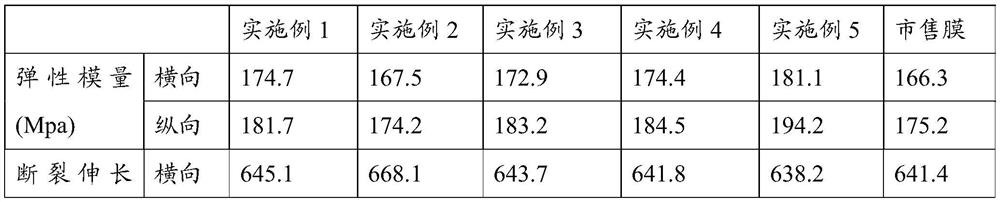

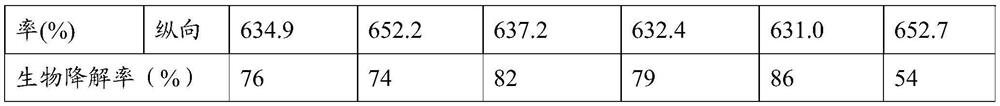

Embodiment 1

[0059] The raw materials are weighed according to the raw material formula of the outer film layer, and the outer film layer includes the following raw materials in parts by weight: 65.5 parts of polylactide, 3.8 parts of polybutylene succinate, 4.2 parts of nanocellulose and isophthalic acid 3 parts of ethylene glycol formate; The polylactide, polybutylene succinate, nanocellulose and ethylene glycol isophthalate are uniformly mixed, and the outer film layer is made into a flat film;

[0060] The raw materials are weighed according to the raw material formula of the inner film layer, and the inner film layer includes the following raw materials in parts by weight: 65.5 parts of polylactic acid-glycolic acid copolymer, 8.3 parts of zinc chloride solution with a mass fraction of 60%, nanocellulose 4.4 parts, 4.5 parts of calcium propionate and 0.5 part of polyethylene terephthalate; the polylactic acid-glycolic acid copolymer, mass fraction are 60% zinc chloride solution, nanoce...

Embodiment 2

[0063] The raw materials are weighed according to the raw material formula of the outer film layer, and the outer film layer includes the following raw materials in parts by weight: 79 parts of polylactide, 8.5 parts of polybutylene succinate, 7.4 parts of nanocellulose and isophthalic 7.5 parts of ethylene glycol formate; The polylactide, polybutylene succinate, nanocellulose and ethylene glycol isophthalate are uniformly mixed, and the outer film layer is made into a flat film;

[0064] The raw materials are weighed according to the raw material formula of the inner film layer, and the inner film layer includes the following raw materials in parts by weight: 79.8 parts of polylactic acid-glycolic acid copolymer, 11.8 parts of zinc chloride solution with a mass fraction of 60%, nanocellulose 8 parts, 7.8 parts of calcium propionate and 5 parts of polyethylene terephthalate; The polylactic acid-glycolic acid copolymer, the mass fraction are 60% zinc chloride solution, nanocellu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com