Tuna oligopeptide powder composition as well as preparation method and application thereof

A technology of tuna and oligopeptides, which is applied in the direction of preparation methods, applications, chemical instruments and methods of peptides, and can solve problems such as death

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The preparation of tuna oligopeptide powder composition:

[0047] In parts by weight, the formula of the tuna oligopeptide powder composition is as follows: 26 parts of tuna oligopeptide powder, 16.8 parts of fish collagen peptide powder, 16 parts of acerola juice powder, 15 parts of peach juice powder, 10 parts of fructooligosaccharide, 10 parts of erythritol, 3 parts of fucoidan, 1.2 parts of compound sour sweetener.

[0048] The compound sour sweetener is formulated from DL-malic acid, citric acid, sodium citrate, and sucralose in a ratio of 3:2:1:1.

[0049] Weigh the above raw and auxiliary materials in proportion, pass through a 60-mesh sieve in turn, transfer the sieved raw and auxiliary materials to the V-shaped mixer, turn on the power and automatically mix for 35 minutes, transfer the evenly mixed powder to the automatic quantitative packaging machine, adjust The measured value is 4g / bag, and it is automatically packed. The automatically packaged products ar...

Embodiment 2

[0051] The preparation of tuna oligopeptide powder composition:

[0052] The formula composition of described tuna oligopeptide powder composition is as follows: 25 parts of tuna oligopeptide powders, 16.5 parts of fish collagen peptide powders, 16.25 parts of Acerola fruit juice powders, 15 parts of peach juice powders, 12.5 parts of fructooligosaccharides, 7.5 parts of erythritol, 3 parts of chitosan oligosaccharide, and 1.0 part of compound sour sweetener.

[0053] The compound sour sweetener is formulated from DL-malic acid, citric acid, sodium citrate, and sucralose in a ratio of 3:2:1:1.

[0054] Weigh the above raw and auxiliary materials in proportion, pass through a 60-mesh sieve in turn, transfer the sieved raw and auxiliary materials to the V-shaped mixer, turn on the power and automatically mix for 35 minutes, transfer the evenly mixed powder to the automatic quantitative packaging machine, adjust The measured value is 4g / bag, and it is automatically packed. The ...

Embodiment 3

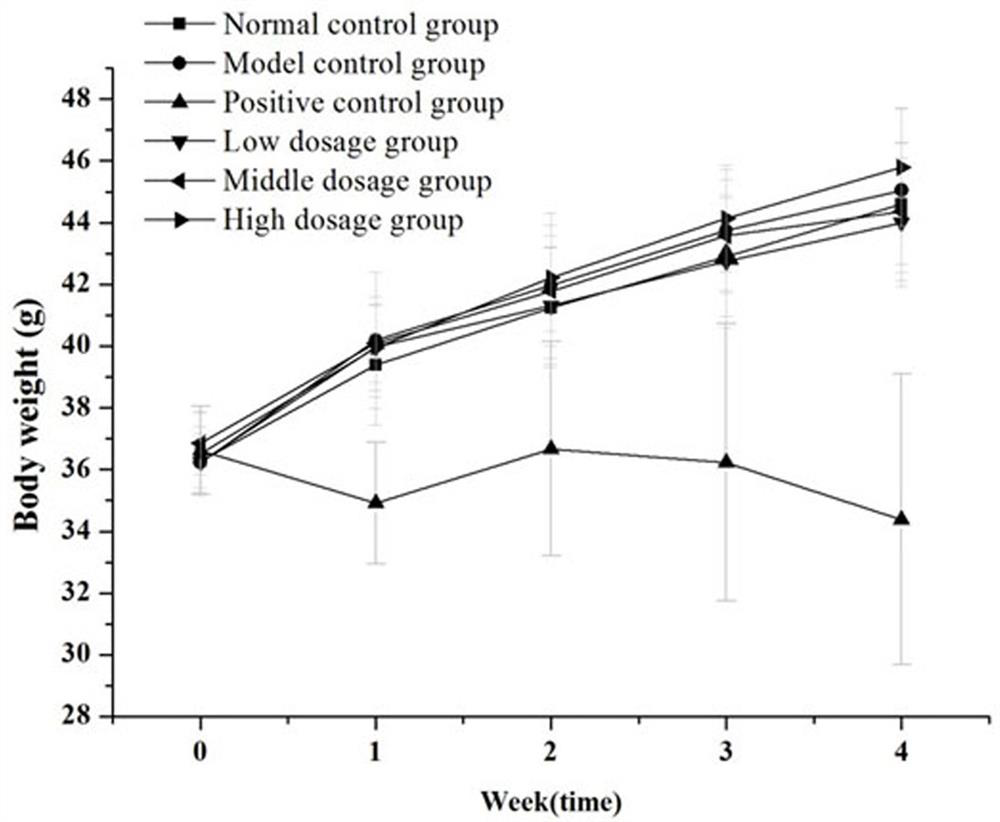

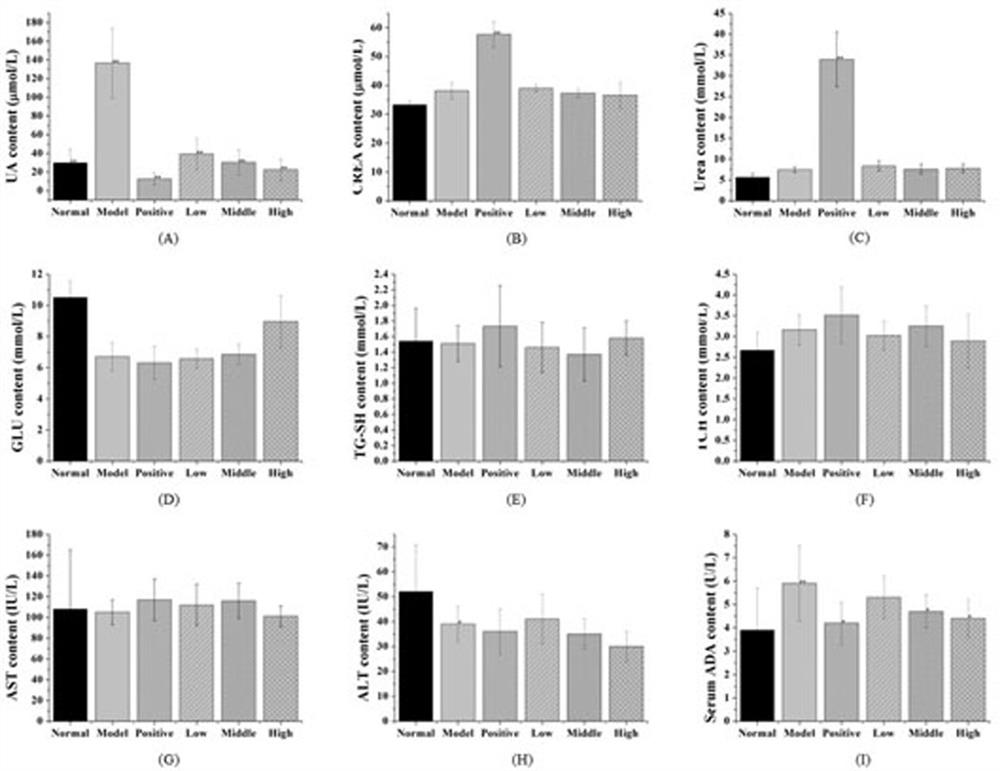

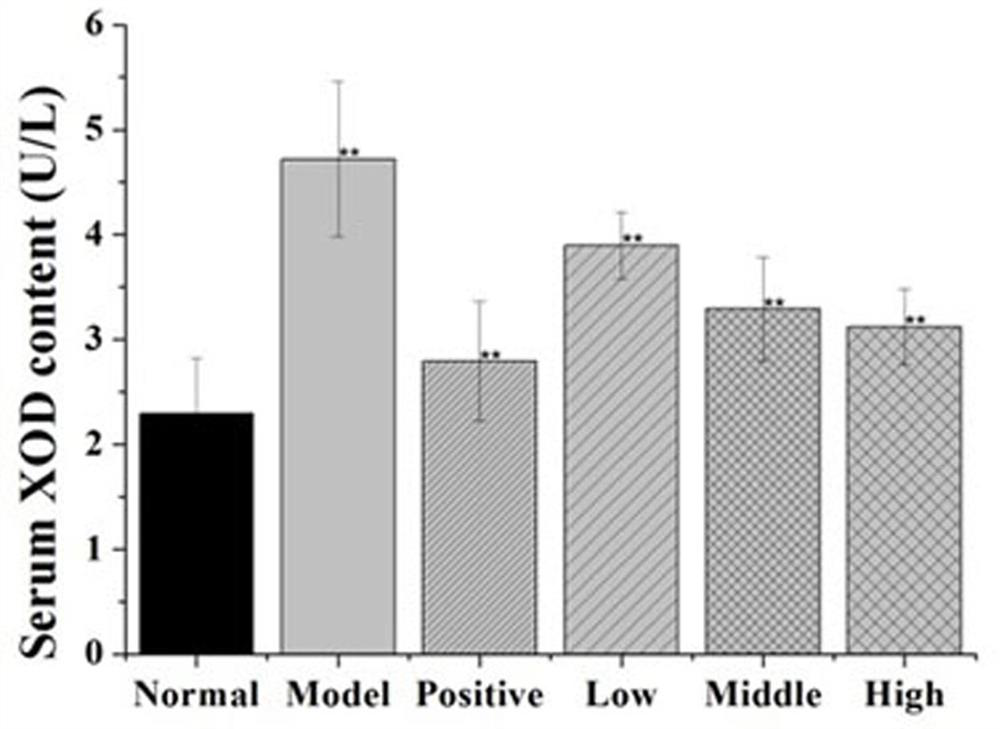

[0056] Effect of tuna oligopeptide powder on uric acid content in serum of mice with hyperuricemia:

[0057] Experimental animals: Kunming mice, SPF grade, 72 males, weighing 20-22 g, purchased from Jinan Pengyue Experimental Animal Breeding Co., Ltd., production license number: SCXK (Lu) 20140007.

[0058] Reagent consumables: Potassium oxonate (lot number: B22D9D78194), hypoxanthine (lot number: Y15J9C52922), allopurinol (lot number: X27J10Y91606) were purchased from Yuanye Biology; sodium carboxymethylcellulose (lot number: 20160602), chloroform (Lot No.: 20180808) were purchased from Sinopharm Chemical Reagent Co., Ltd.; XOD (Lot No.: 01 / 2020) ELISA Kit, Jianglai Biotech; RevertAid First Strand cDNA Synthesis Kit (Lot No.: 00775466), American ThermoFisher; Isopropanol ( Batch number: F715BA1004), Shanghai Sangong; TRIzol (batch number: #BCBX0488), Sigma, USA; ChamQ SYBR qPCR Master Mix (batch number: 7E381B9), Nanjing Novizym Biotechnology Co., Ltd.; DEPC treated water (ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com