Production device and preparation method of organic sodium alcoholate

A production device and technology for organic alcohols, applied in the field of preparation of organic alcohol alkali metal salts, can solve problems such as safety accidents, prolongation of process time, fire or explosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

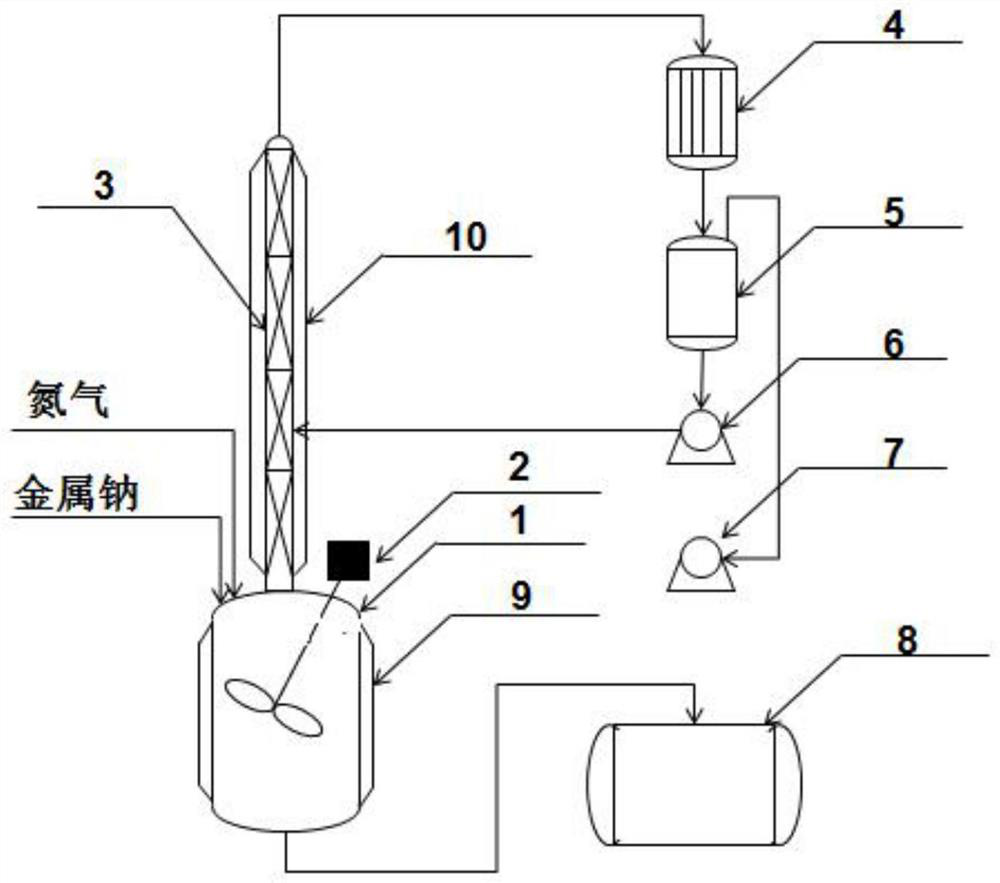

[0031] see figure 1 Shown, a kind of production device and preparation method of organic sodium alkoxide, comprise still anti-rectification device, described still anti-rectification device comprises tower still 1, and described tower still 1 is fixed with the outside of tower still that can be heated and cooled. Jacket 9, the inner cover of the tower kettle 1 is provided with an agitator 2, the top of the tower kettle 1 is connected to the lower end inlet of the rectification column 3, and the outer surface of the rectification column 3 is provided with a steam heating insulator 10, so The bottom of the tower kettle 1 is connected with a finished product tank 8, the top outlet of the rectifying column 3 is connected to the inlet of the total reflux condenser 4, and the bottom outlet of the total reflux condenser 4 is connected to the top inlet of the receiving tank 5, so The outlet at the bottom of the receiving tank 5 is respectively connected with a material reflux pump 6 a...

Embodiment 1

[0044] Weigh 1 part of metal sodium, add it to the tower kettle 1 and replace it with nitrogen for 3 times, open the vacuum device 7 to pump the pressure in the reactor to -0.1MPa, add 0.01% hydroquinone to the allyl alcohol, and Inhale 30 parts of allyl alcohol into the tower kettle 1. Turn on the stirrer 2 and keep the vacuum line of the vacuum pump 7 in an open state. Turn on the jacketed steam heating of the tower kettle 1, raise the temperature to 50°C, stop the steam heating, and control the temperature of the tower kettle 1 at 50±5°C. The allyl alcohol vapor enters the total reflux condenser 4 through the rectification tower 3, and enters the receiving tank 5 after being condensed into a liquid. When the liquid level gauge liquid level of the receiving tank 5 reaches 25%, the material reflux pump 6 is opened to keep the receiving tank The liquid level of the liquid level gauge in 5 remains unchanged, and the remaining materials are pumped back to the rectification towe...

Embodiment 2

[0055] Weigh 52.8 parts of allyl alcohol and 3.3 parts of catalyst C-153 into the polyether reactor, replace with nitrogen for 3 times, and pump the polyether reactor down to -0.1MPa again. Turn on the heating device to raise the temperature of the polyether reactor to 100°C, open the ethylene oxide feed valve, and first feed 1 part of ethylene oxide until the polymerization of ethylene oxide in the polyether reactor begins (temperature rises, pressure drop), continue to feed 4032 parts of ethylene oxide, control the reaction temperature at 120±5°C, and the reaction pressure ≤0.4MPa, after the ethylene oxide feeding is completed, continue the heat preservation reaction for 30min, cool down the polyether reactor to 50°C, and then Vacuum degassing to -0.1MPa, and finally pressurize nitrogen to normal pressure and discharge. Obtained 4100 parts of light brown viscous liquid, named as PEG-1. Tested by hydroxyl value method, the weight average molecular weight is 2390; tested by G...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tower diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com