Supported catalyst for preparing 2,5-dichlorophenol through catalytic oxidation, and application thereof

A supported catalyst, dichlorophenol technology, applied in physical/chemical process catalysts, molecular sieve catalysts, preparation of organic compounds, etc., can solve the problems of harsh reaction conditions, environmental pollution, unsatisfactory catalytic effect, etc., and achieve high selectivity , the effect of improving the catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

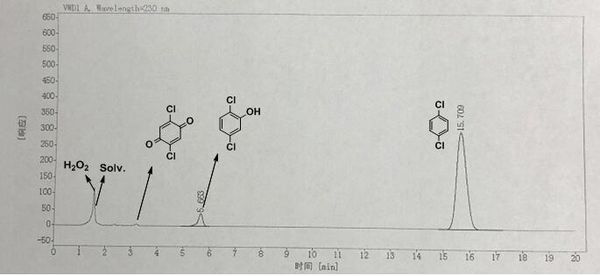

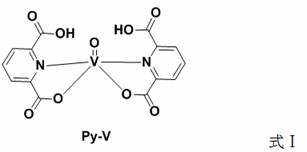

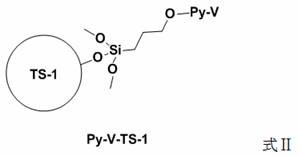

[0028] A supported catalyst for preparing 2,5-dichlorophenol by catalytic oxidation. The catalyst is a vanadium oxide / TS-1 heterogeneous catalyst obtained by combining vanadyl acetylacetonate and TS-1 titanium-silicon molecular sieve. Dissolve 5g of vanadyl acetylacetonate with 125g of methanol to obtain a methanol solution of vanadyl acetylacetonate, then add 30g of TS-1 titanium-silicon molecular sieve, stir and impregnate at room temperature for 2.5h and then filter, the filter cake is freeze-dried to remove methanol and placed in a muffle Calcined in the furnace at 550°C for 2 hours, the brown-gray powdery vanadium oxide / TS-1 supported catalyst product was obtained. The vanadium content in the product was 4.93% as measured by ICP-AES, and the yield was 100% based on vanadium.

Embodiment 2

[0030] A supported catalyst for preparing 2,5-dichlorophenol by catalytic oxidation. The catalyst is a vanadium oxide / TS-1 heterogeneous catalyst obtained by combining vanadyl acetylacetonate and TS-1 titanium-silicon molecular sieve. Dissolve 3g of vanadyl acetylacetonate with 90g of methanol to obtain a methanol solution of vanadyl acetylacetonate, then add 22.5g of TS-1 titanium-silicon molecular sieve, stir and impregnate at room temperature for 2h, then filter, and the filter cake is freeze-dried to remove methanol and placed in a muffle Calcined in the furnace at 600°C for 1 hour, the brown-gray powdery vanadium oxide / TS-1 supported catalyst product was obtained. The vanadium content in the product was 2.96% as measured by ICP-AES, and the yield was 100% based on vanadium.

Embodiment 3

[0032] A supported catalyst for preparing 2,5-dichlorophenol by catalytic oxidation. The catalyst is a vanadium oxide / TS-1 heterogeneous catalyst obtained by combining vanadyl acetylacetonate and TS-1 titanium-silicon molecular sieve. Dissolve 1 g of vanadyl acetylacetonate with 20 g of methanol to obtain a methanol solution of vanadyl acetylacetonate, then add 25 g of TS-1 titanium-silicon molecular sieve, stir and impregnate at room temperature for 3 hours, then filter, and the filter cake is freeze-dried to remove methanol and placed in a muffle furnace Calcined at 500°C for 3 hours, the brown-gray powdery vanadium oxide / TS-1 supported catalyst product was obtained. The vanadium content in the product was 1.07% as measured by ICP-AES, and the yield was 100% based on vanadium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com