Photo-anode for slowing down corrosion in photoelectrocatalysis wastewater treatment process by using amorphous cobalt phosphate Co-Pi, preparation method and application thereof

A technology of photoelectric catalysis and wastewater treatment, applied in the direction of light water/sewage treatment, water/sewage treatment, chemical instruments and methods, etc. Photoelectrode and other problems to achieve the effect of inhibiting self-oxidation corrosion, easy recycling and slowing down photocorrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] This example compares the photoelectrochemical properties of different electrode films.

[0050] (1) BiVO 4 Preparation of the electrode film: Before preparing the electrode film, the fluorine-doped tin oxide substrate (1×3cm 2 ) immersed in the mixture of isopropanol: acetone: ultrapure water = 1:1:1 (volume ratio) and sonicate the front and back sides for 15 minutes respectively, and the Bi(NO 3 ) 3 ·5H 2 O (0.485g) dissolved in 150mL ethylene glycol and water (EG: H 2 O=2:1, v:v) in the mixed solution as the electrolyte, deposited at a constant voltage of -0.6V vs.Ag / AgCl for 7, 8, 9, 10min to obtain the Bi metal electrode film; 0.106g acetylacetonate oxygen Vanadium was dissolved in 2.0mL dimethyl sulfoxide solvent as the source of vanadium; 200 μL dimethyl sulfoxide solution of vanadyl acetylacetonate was evenly added dropwise on the Bi metal film, so that the dimethyl sulfoxide of vanadyl acetylacetonate The surface of the Bi metal film was immersed in the su...

Embodiment 2

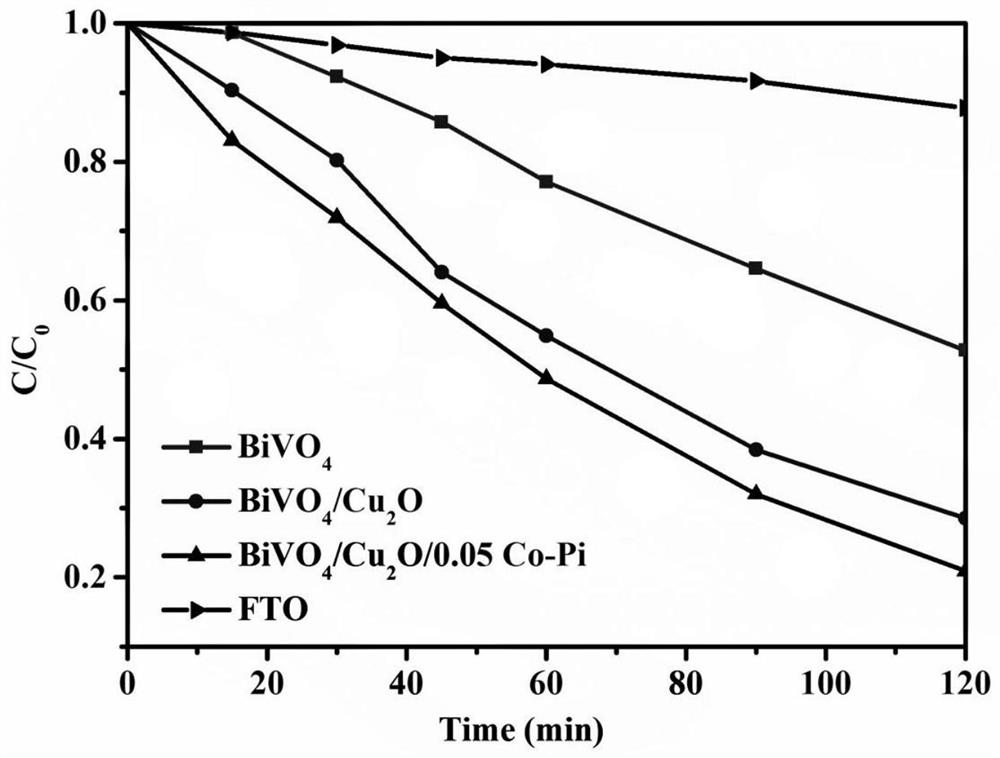

[0059] In this embodiment, the photocurrent variation with time of different electrode films is compared.

[0060] (1) BiVO 4 Preparation of the electrode film: Before preparing the electrode film, the fluorine-doped tin oxide substrate (1×3cm 2 ) immersed in the mixture of isopropanol: acetone: ultrapure water = 1:1:1 (volume ratio) and sonicate the front and back sides for 15 minutes respectively, and the Bi(NO 3 ) 3 ·5H 2 O (0.485g) dissolved in 150mL ethylene glycol and water (EG: H 2 The mixed solution of O=2:1, v:v) was used as the electrolyte, and the Bi metal electrode film was obtained by depositing at a constant voltage of -0.6V vs. Ag / AgCl for 7min. Dissolve 0.106 g of vanadyl acetylacetonate in 2.0 mL of dimethyl sulfoxide solvent as a source of vanadium. 200 μL of dimethyl sulfoxide solution of vanadyl acetylacetonate was evenly added dropwise on the Bi metal film, so that the dimethyl sulfoxide solution of vanadyl acetylacetonate was immersed in the surface ...

Embodiment 3

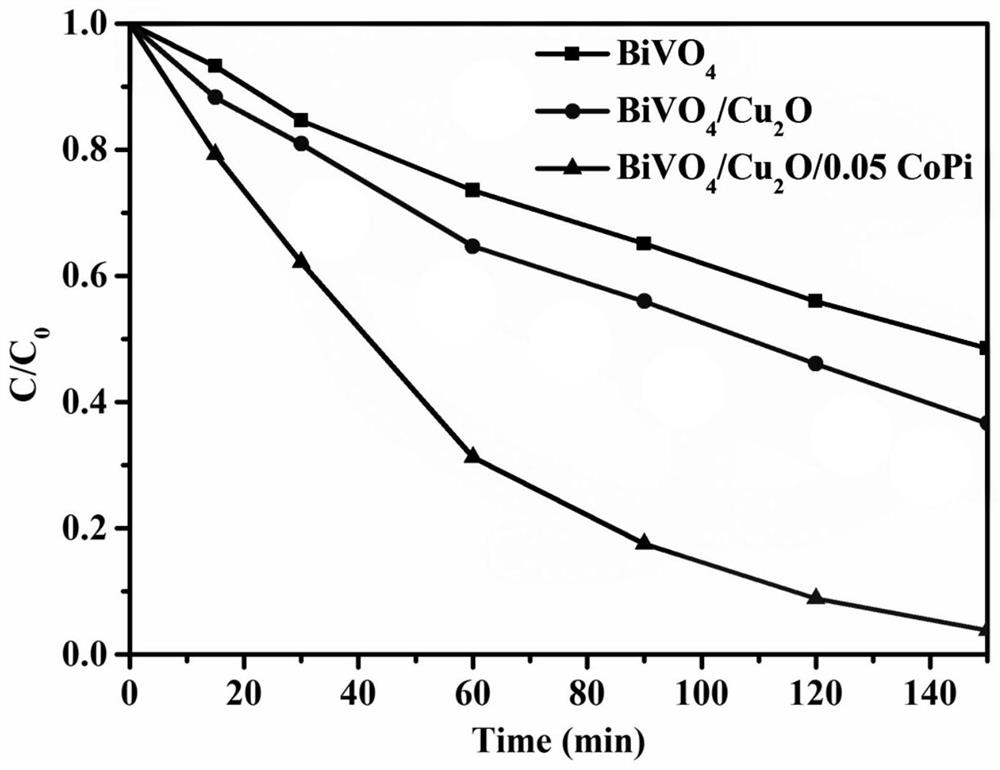

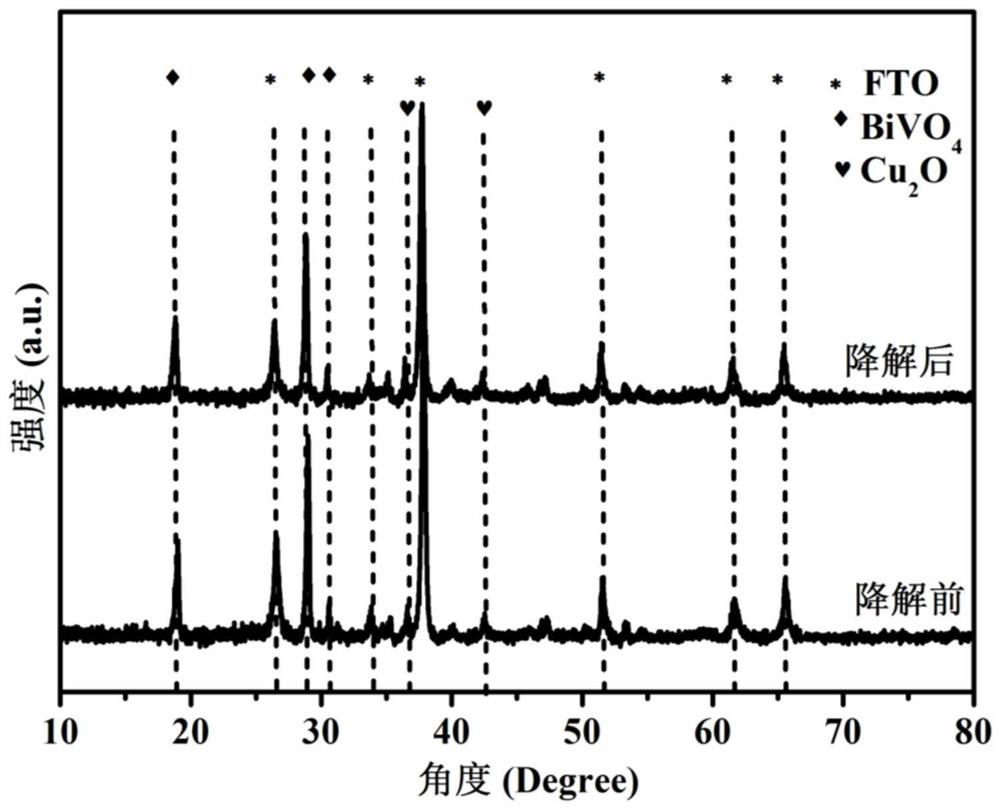

[0069] This example compares the difference in the performance of different photoanodes for photocatalytic degradation of ciprofloxacin (CIP).

[0070] (1) BiVO 4 、BiVO 4 / Cu 2 O. BiVO 4 / Cu 2 The preparation method of O / 0.05 Co-Pi electrode film is with the step (1) (2) (3) in the embodiment 2;

[0071] (2) Using 30mg / L ciprofloxacin pollutant as the electrolyte, the photoelectrocatalytic degradation activity of different prepared photoanodes was studied under the condition of 0.6V vs. Ag / AgCl voltage and AM1.5G illumination.

[0072] (3) A three-electrode quartz electrolytic cell with a volume of 100mL is used as a reactor, and a total of 50mL of 30mg / L ciprofloxacin pollutants and 0.1M potassium phosphate buffer are added to the reactor, and the prepared photoanode is immersed in the electrolyte , carry out the reaction under normal temperature (25°C) conditions, and take samples at fixed points for analysis;

[0073] The degradation curves of different photoanodes fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com