Method for extracting auricularia auricular polysaccharide by using biological enzyme method

A black fungus polysaccharide and bio-enzyme technology, which is applied in the field of enzymatic extraction of black fungus polysaccharides, can solve the problems that affect the sustainable development of the industry and the difference in wall breaking effect, and achieve the effect of improving biological activity and good sensory properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

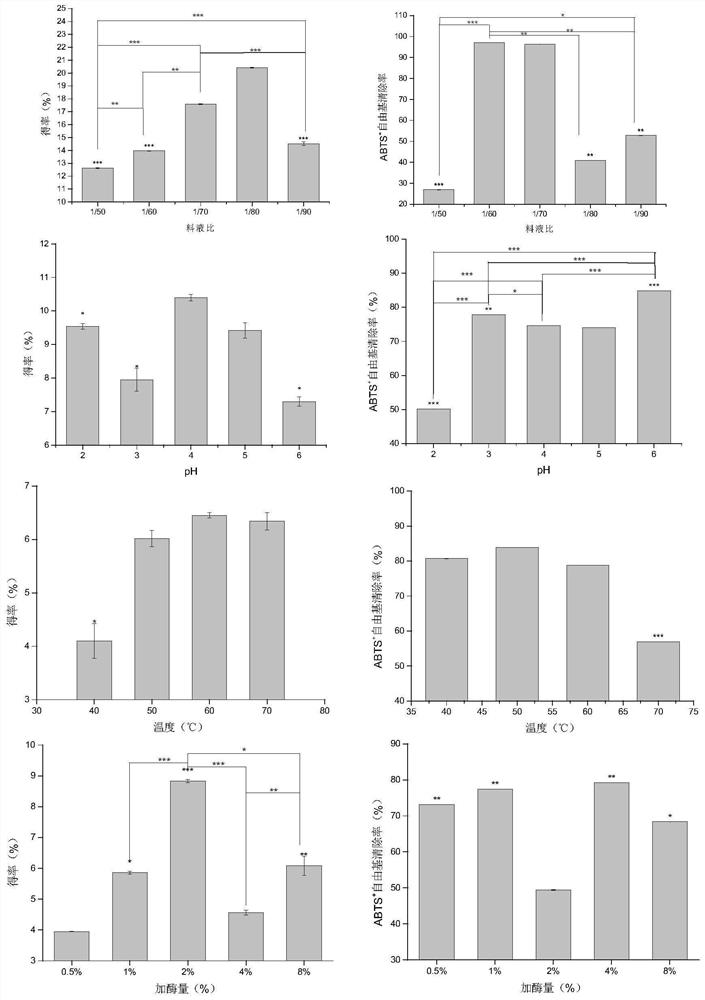

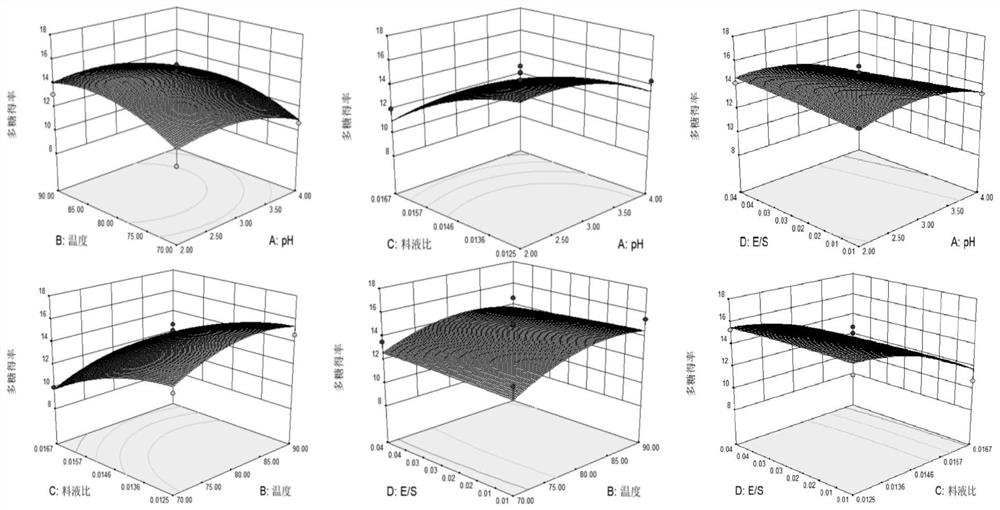

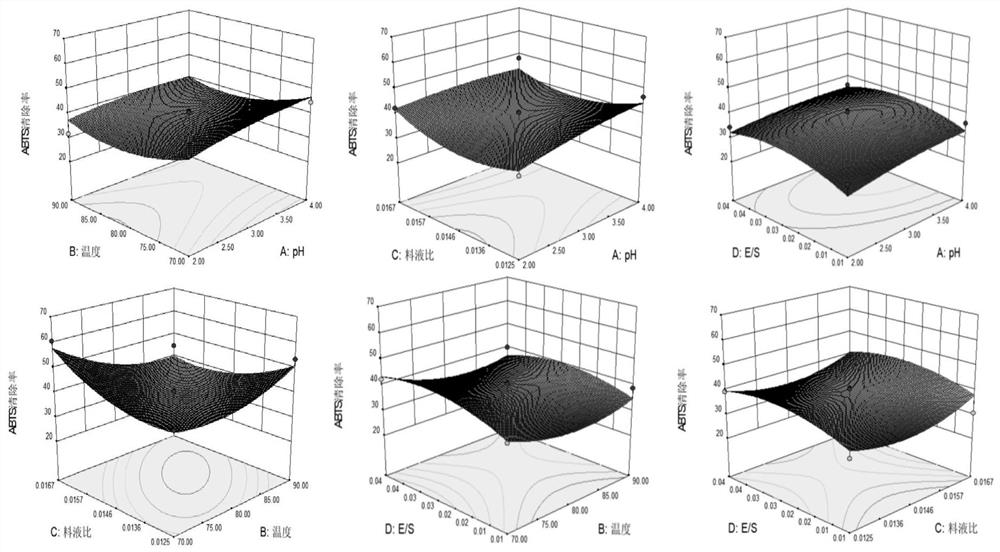

Method used

Image

Examples

Embodiment 1

[0048] 1 Materials and reagents

[0049] Black fungus (produced in Xiaoxing'an Mountains, Yanjun Farm, Luobei County, Heilongjiang Province). Before use, place the black fungus powder in a 50°C oven for drying, pulverize, and screen the black fungus powder with a mesh number of 150-200 mesh for future use.

[0050] Phenol, concentrated sulfuric acid, sodium hydroxide, ethanol, sodium dihydrogen phosphate, disodium hydrogen phosphate, potassium dihydrogen phosphate, potassium persulfate, chloroform, n-butanol, acetone, ferrous sulfate, ferrous chloride, ferric chloride , potassium ferricyanide, ethylenediaminetetraacetic acid (EDTA), glucose, 1,1-diphenyl-2-picryhydrazyl (DPPH), hydrogen peroxide, phenanthrenolazine (Ferrozine), Nile red fluorescent dye, ascorbic acid (Vc), atorvastatin calcium, 2,2-azino-bis(3-ethyl-benzothiazoline sulfonic acid-6) ammonium salt (ABTS), and the water used in the experiment was deionized water.

[0051] N2 wild-type Caenorhabditis elegans and...

Embodiment 2

[0201] Black fungus pretreatment: Take 10g of black fungus powder (passed through a 150-200 mesh sieve) and add it to 600mL of deionized water, swell at 25°C for 12h, then freeze in a -20°C refrigerator for 60min, and thaw in a constant temperature water bath at 20°C for 3 times Freeze-thaw cycle pretreatment, and then freeze-drying (initial temperature is -30 ° C, vacuum degree is 80 Pa), to obtain 10 g of pretreated black fungus powder.

[0202] Black fungus polysaccharide extraction: take 10g of pretreated black fungus powder, add 600mL deionized water, then add 0.4g cellulase and 0.6g papain (that is, half of the optimal enzyme amount), and Under the conditions of 55°C, pH 5.3, and solid-liquid ratio of 1g / 60mL, act for 3.0h to fully and effectively break the cell wall of black fungus; add 0.6g of mild-acting β-glucanase according to E / S 6.0%, and under other conditions Under the same conditions (55°C, pH 5.3), act for 2 hours. Then heat to boil for 15min to inactivate th...

Embodiment 3

[0234] Accurately weigh 20 g of black fungus powder (150-200 mesh sieve) and dissolve in 560 mL of deionized water, swell for 16 h, then freeze in a -20 °C refrigerator for 50 min, thaw in a constant temperature water bath at 20 °C, perform 4 freeze-thaw cycles, and then After freeze-drying (the initial temperature is -30° C., and the vacuum degree is 80 Pa), 20 g of pretreated black fungus powder is obtained.

[0235] Add 20g of black fungus powder after pretreatment, add 0.8g cellulase and 1.2g papain (that is, according to half of the optimal enzyme amount) and 1200mL deionized water, and then at an action temperature of 45°C, pH 4.0, Act for 1.0h under the condition of ratio 1 / 60 to fully and effectively break the cell wall of black fungus; then add 0.8g of mild-acting β-glucanase according to E / S 4.0%, and act at 45°C and pH 4.0 2h. Prepare 6.54g of black fungus polysaccharides with the method of Example 2, the average polysaccharide yield is 35.06%, ABTS + The scavengi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com