A method for separating and purifying betulinic acid from lotus pod shells

A technology for separation and purification of betulinic acid, applied in organic chemistry, steroids, etc., can solve the problems of low technical content, waste of lotus resources, and lack of attention, and achieve simple process operation, save time, and reduce the use of reagents Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

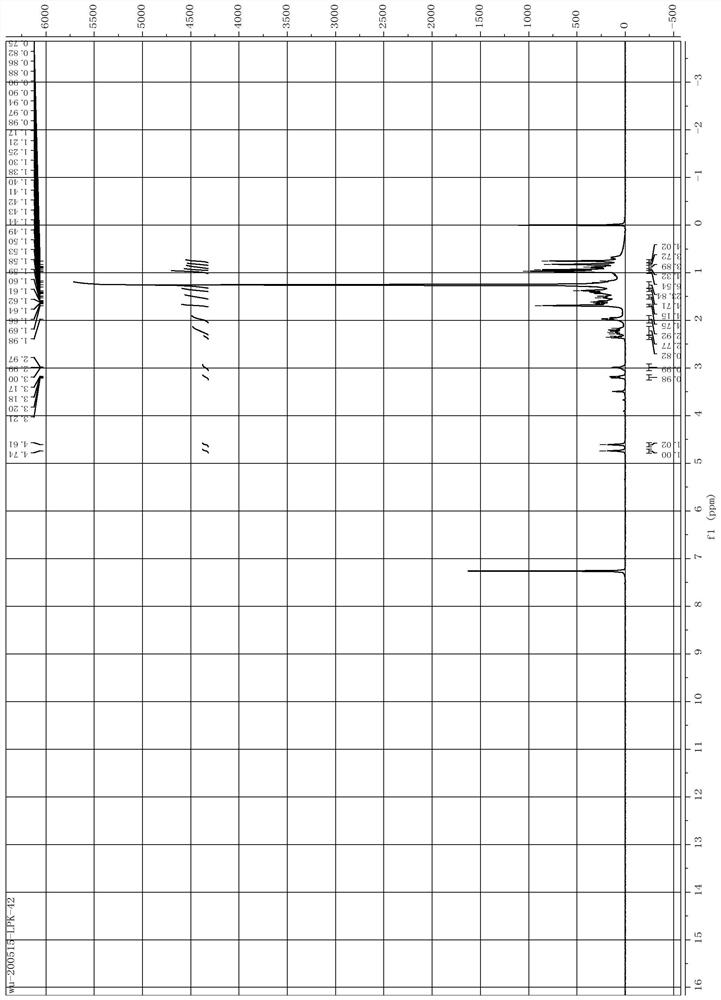

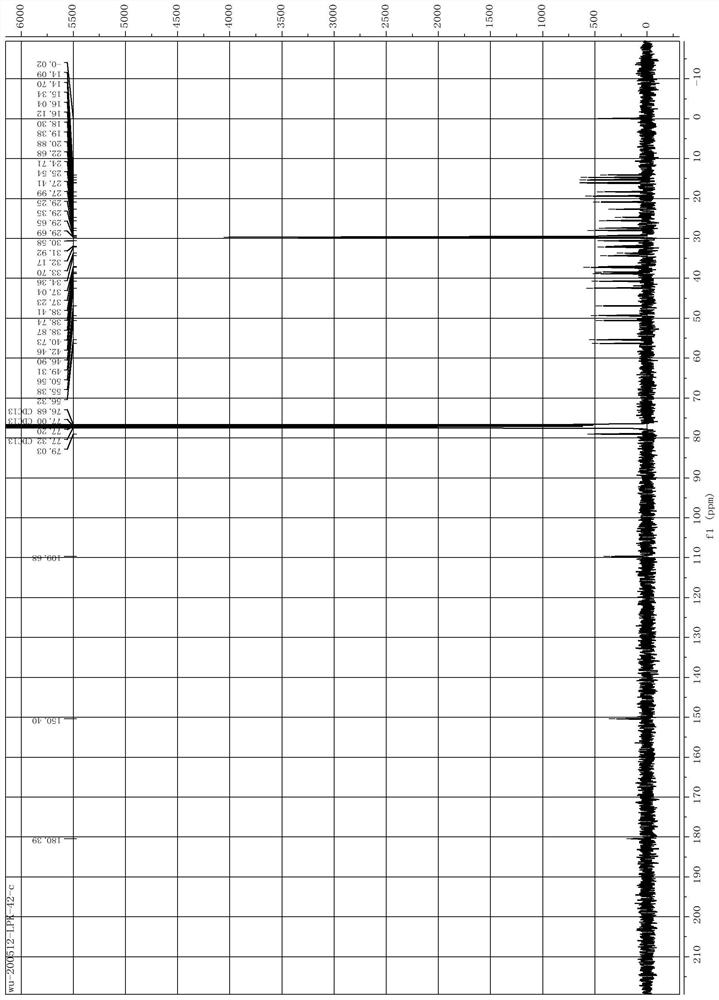

Image

Examples

Embodiment 1

[0029] The raw material of the lotus pod shell is crushed, weighed 1kg, added 10L of 70% ethanol aqueous solution, pretreated in the flash extractor for 30min, then refluxed for 2h, obtained the extract by filtration, and added a mass fraction of 20% to the extract % sodium hydroxide solution adjusted to PH=8, concentrated to alcohol content of 10%; the concentrated solution was acid-adjusted, adjusted to pH=2 with hydrochloric acid, heated to reflux for 30 minutes, filtered after cooling, and the filtrate was treated with 20% sodium hydroxide The pH of the solution was adjusted to 10, and after standing for 10 hours, the precipitate was obtained by centrifugation, and the supernatant was discarded; low-polar petroleum ether was added to the precipitate for elution, and the fat-soluble substances in the precipitate were removed; 3 times the mass of methanol is thermally dissolved, and 10% activated carbon is added to the above dissolved solution, adsorbed at 60°C for 1h, filter...

Embodiment 2

[0031]The raw material of the lotus pod shell is crushed, weighed 1kg, added 20L of 80% ethanol aqueous solution, pretreated in the flash extractor for 10min, then refluxed for 1h, obtained the extract by filtration, and added a mass fraction of 5 % Potassium hydroxide solution adjusted to PH=10, concentrated to alcohol content of 30%; acid-adjusted the concentrated solution, adjusted to PH=3 with citric acid, heated to reflux for 60 minutes, filtered after cooling, and the filtrate was oxidized with 10% hydroxide The potassium solution was adjusted to PH=10, and after standing for 8 hours, the precipitate was obtained by centrifugation, and the supernatant was discarded; low-polarity n-hexane was added to the precipitate for elution, and the fat-soluble substances in the precipitate were removed; 3 times the mass of methanol is thermally dissolved, and 5% activated carbon is added to the above dissolved solution, adsorbed at 60° C. for 1 hour, filtered, and the filtrate is col...

Embodiment 3

[0033] The raw material of the lotus pod shell is crushed, weighed 1kg, added 15L of 60% ethanol aqueous solution, pretreated in the flash extractor for 20min, then refluxed for 1.5h, and the extract was obtained by filtration, and the mass fraction was added to the extract. After adjusting PH=9 with 15% sodium bicarbonate solution, concentrate to alcohol content of 20%; adjust acidity of the concentrated solution, adjust solution PH=4 with formic acid, heat and reflux for 60 minutes, filter after cooling, and filter the filtrate with 15% sodium carbonate The pH of the solution was adjusted to 11, and after standing for 10 hours, the precipitate was obtained by centrifugation, and the supernatant was discarded; low-polarity cyclohexane was added to the precipitate for elution, and the fat-soluble substances in the precipitate were removed; continue to add 3 times the mass of methanol is thermally dissolved, and 10% activated carbon is added to the above dissolved solution, adso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com