Bone filling prosthesis and preparation technology thereof

A prosthesis and process technology, applied in the direction of prosthesis, bone implants, medical science, etc., can solve the problems of osseointegration and infection, tissue damage, poor support ability, etc., and improve the antibacterial and bacteriostatic performance and biological Active, promoting bone formation, inhibiting bone resorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

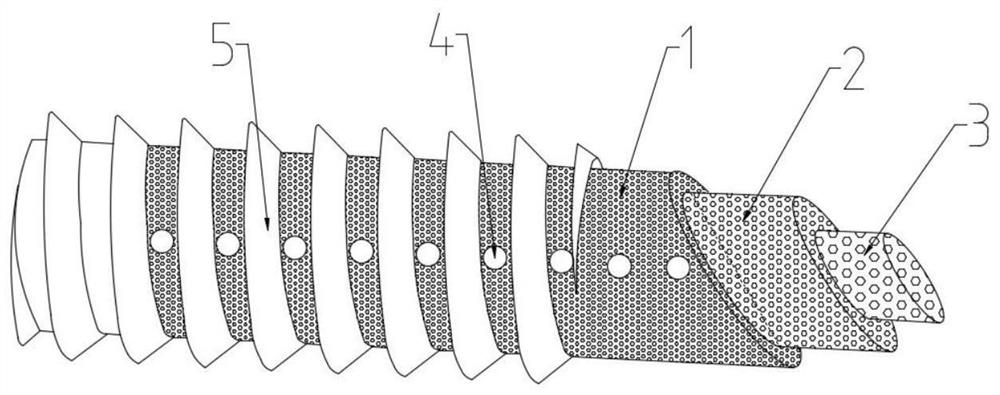

[0046] Embodiment 1. Step 1. Prepare a bone filling prosthesis with a gradient pore structure. The pore diameter of the gradient pore structure is 200 μm, the porosity of the outer pore layer is 60%, the porosity of the middle pore layer is 60%, and the porosity of the central pore layer is 60%. The porosity is 90%;

[0047] Step 2. Cleaning and drying: First, ultrasonically clean the bone filling prosthesis with acetone for 5 minutes, then spray and rinse it with deionized water, and finally dry it at 40°C;

[0048] Step 3, oxidation treatment includes:

[0049] 1) Prepare a micro-arc oxidation electrolyte, which includes 0.015mol / L sodium hexametaphosphate, 0.14mol / L sodium hydroxide, 0.4mol / L calcium element, and 0.25mol / L phosphorus by volume in the electrolyte Elements, Ca element comes from calcium acetate; P element comes from sodium glycerophosphate;

[0050] 2) Oxidation film formation, with the bone filling prosthesis as the anode and stainless steel as the cathode...

Embodiment 2

[0059] Example 2, step 1, preparing a bone filling prosthesis with a gradient pore structure, the pore diameter of the gradient pore structure is 800 μm, the porosity of the outer pore layer is 60%, the porosity of the middle pore layer is 80%, and the porosity of the central pore layer is 800 μm. The porosity is 90%;

[0060] Step 2. Cleaning and drying: First, ultrasonically clean the bone filling prosthesis with acetone for 10 minutes, then spray and rinse it with deionized water, and finally dry it at 40°C;

[0061] Step 3, oxidation treatment includes:

[0062] 1) Prepare a micro-arc oxidation electrolyte, which includes 0.015mol / L sodium hexametaphosphate, 0.14mol / L sodium hydroxide, 0.6mol / L calcium element, and 0.875mol / L phosphorus in parts by volume. Elements, Ca element comes from calcium chloride and calcium dihydrogen phosphate; P element comes from sodium dihydrogen phosphate and disodium hydrogen phosphate;

[0063] 2) Oxidation film formation, with the bone f...

Embodiment 3

[0072] Example 3, step 1, preparing a bone filling prosthesis with a gradient pore structure, the pore diameter of the gradient pore structure is 500 μm, the porosity of the outer pore layer is 60%, the porosity of the middle pore layer is 65%, and the porosity of the central pore layer The porosity is 90%;

[0073] Step 2. Cleaning and drying: First, ultrasonically clean the bone filling prosthesis with acetone for 7 minutes, then spray and rinse it with deionized water, and finally dry it at 40°C;

[0074] Step 3, oxidation treatment includes:

[0075] 1) Prepare the micro-arc oxidation electrolyte, which includes 0.015mol / L sodium hexametaphosphate, 0.14mol / L sodium hydroxide solution, 0.5mol / L calcium element, and 0.65mol / L phosphorus in the electrolyte by volume. Elements, Ca element comes from calcium lactate and calcium oxide; P element comes from sodium hexametaphosphate and sodium polyphosphate;

[0076] 2) Oxidation film formation, with the bone filling prosthesis ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com