Mullite-loaded W-promoted Co-based catalyst for hydrogen production by auto-thermal reforming of acetic acid

An autothermal reforming and catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, heterogeneous catalyst chemical elements, etc., can solve the problem of easy oxidation and easy sintering of active metals. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0029] Take by weighing 18.753g aluminum nitrate nonahydrate (Al(NO 3 ) 3 9H 2 (O) and 2.322g tetraethyl orthosilicate (TEOS) were added into 80mL ethanol to obtain a white solution, and 36.701g ammonium carbonate ((NH 4 ) 2 CO 3 ) into the white solution, heated in a water bath at 60°C and vigorously stirred for 5 hours, dried in an oven at 120°C for 64 hours, and then calcined in a muffle furnace at 1200°C for 4 hours to obtain the carrier Mullite; 1.166g cobalt nitrate and 1.314g Dissolve ammonium tungstate in deionized water, stir thoroughly for 3 hours, then add 1.60g Mullite carrier, continue stirring for 2 hours, put it in an oven at 105°C for 16 hours, and then bake it in a tube furnace at 700°C for 4 hours to obtain CWM-V Catalyst, the weight percentage of this catalyst is composed of: cobalt oxide (CoO) is 15.0%, tungsten oxide (WO 3 ) is 5.0%, Mullite (3Al 2 o 3 -2SiO2 2 ) is 80.0%.

[0030] The reactivity evaluation of autothermal reforming of acetic acid ...

Embodiment 1

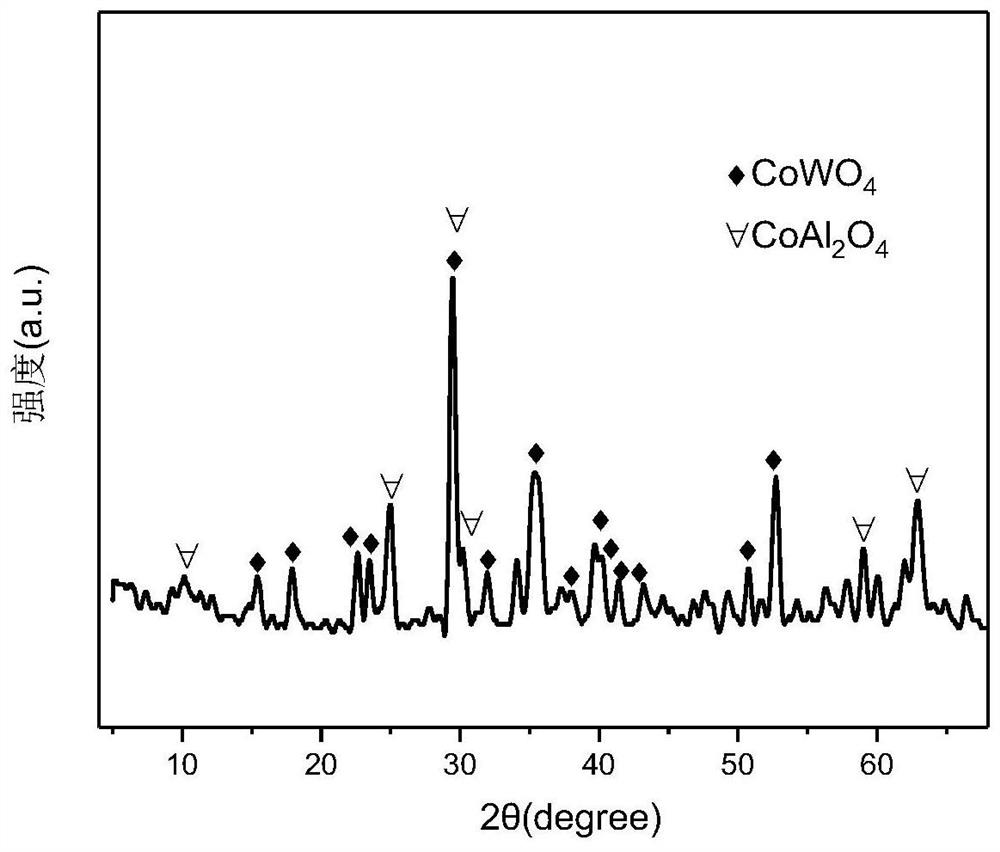

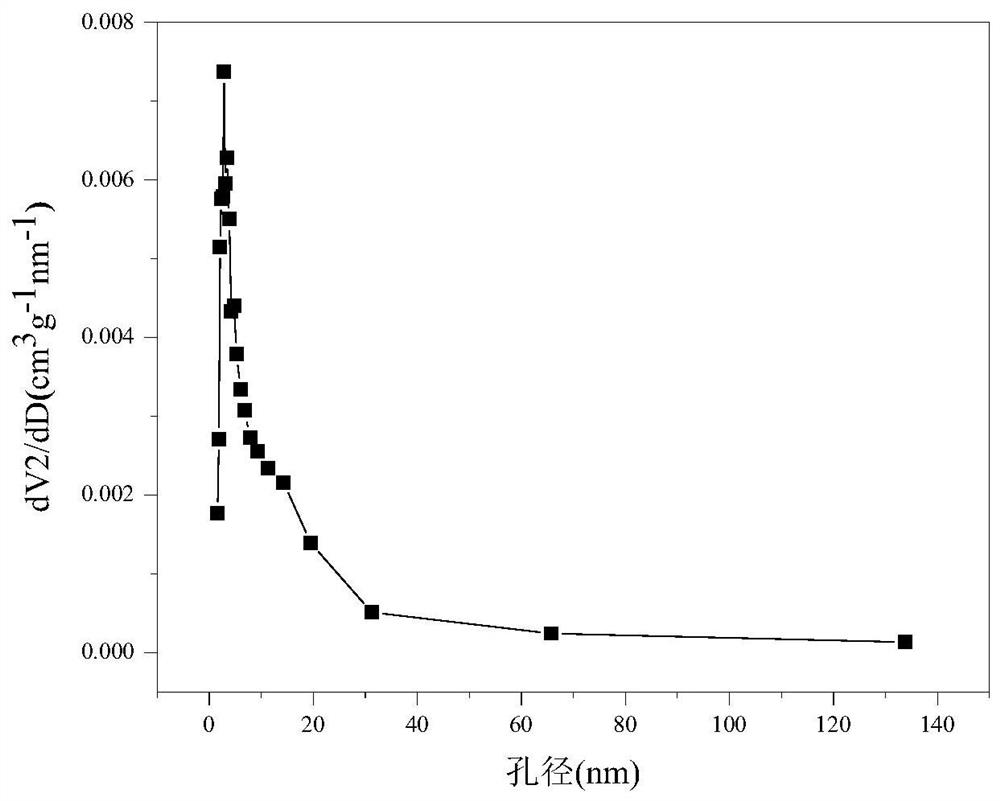

[0033] Take by weighing 18.753g aluminum nitrate nonahydrate (Al(NO 3 ) 3 9H 2 O) and 2.322g tetraethyl orthosilicate (TEOS) were added into 80mL ethanol to obtain a white solution, and 36.701g ammonium carbonate ((NH 4 ) 2 CO 3 ) into the white solution, heated in a water bath at 60°C and stirred vigorously for 5 hours, dried in an oven at 120°C for 64 hours, and then calcined in a muffle furnace at 1200°C for 4 hours to obtain the carrier Mullite; mix 1.166g of cobalt nitrate and 0.263g of tungsten Dissolve ammonium acid in deionized water, stir thoroughly for 3 hours, then add 1.680g Mullite carrier, continue stirring for 2 hours, put the drug in an oven at 105°C for 16 hours, put the dried drug in a tube furnace at 700°C for 4 hours , the CWM-I catalyst was obtained, and the spinel-containing CoAl supported on Mullite was formed 2 o 4 and composite oxide CoWO 4 The mesoporous composite oxide catalyst with Co-W-Al-O active center, its typical crystal structure is sho...

Embodiment 2

[0036] Take by weighing 18.753g aluminum nitrate nonahydrate (Al(NO 3 ) 3 9H 2 O) and 2.322g tetraethyl orthosilicate (TEOS) were added into 80mL ethanol to obtain a white solution, and 36.701g ammonium carbonate ((NH 4 ) 2 CO 3 ) was added to the above white solution, heated in a water bath at 60°C and vigorously stirred for 5h, dried in an oven at 120°C for 64h, and then calcined in a muffle furnace at 1200°C for 4h to obtain the carrier Mullite; 1.166g of cobalt nitrate and 0.536g Dissolve ammonium tungstate in deionized water, stir thoroughly for 3 hours, then add 1.659g Mullite carrier, continue stirring for 2 hours, put the drug in an oven at 105°C for 16 hours, put the dried drug in a tube furnace at 700°C for roasting 4h, the CWM-II catalyst was obtained, and spinel-containing CoAl supported on Mullite was formed 2 o 4 and composite oxide CoWO 4 The mesoporous composite oxide catalyst with Co-W-Al-O active center, its typical crystal structure is shown in the at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com