MOF composite material with antibacterial function as well as preparation method and application thereof

A composite, functional technology, used in pharmaceutical formulations, bandages, surgery, etc., to solve problems such as lack of interaction, reduced bactericidal activity, short lifespan and diffusion distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1, UIO-66-NH-CO-MoS 2 Preparation of Nanomaterials

[0037] 50mg MoS 2-COOH nanoparticles were uniformly dispersed in 25mL DMF, which was recorded as the dispersion ①; then 287.55mg HOBT and 202.65mg EDC·HCl were dissolved in 1.5mL DMF, which was recorded as the solution ②; then the solution ② was added to the dispersion ①, and the After stirring for 45 min in ice bath, 1 mL of TEA was added, and after stirring evenly, 60 mg of UIO-66-NH 2 Added to the above mixed system, stirred at room temperature for 12h. After the reaction, centrifuge (9000r / min) for 6min, discard the supernatant, wash the collected product 3 times with DMF, wash 3 times with absolute ethanol, and obtain the nanomaterial UIO-66-NH-CO after vacuum drying -MoS 2 . 101.5 mg of the nanomaterial product was obtained, with a yield of 92.3% and a purity of about 91%.

Embodiment 2

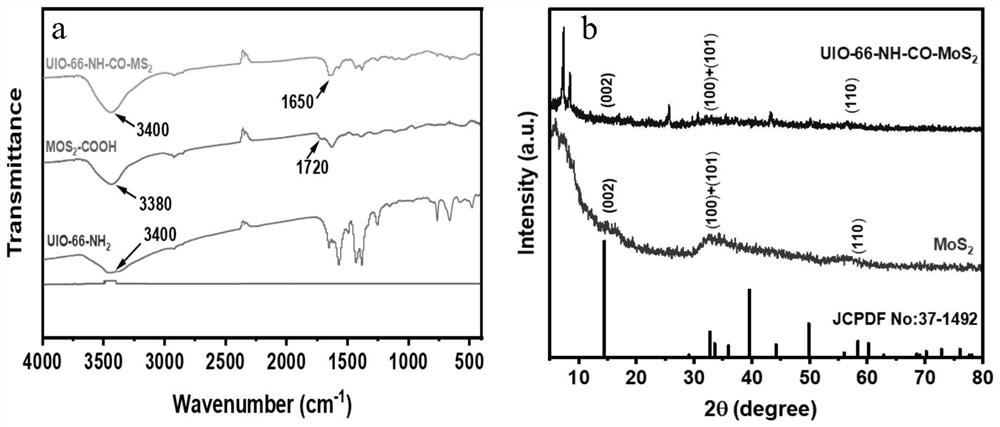

[0038] Example 2, UIO-66-NH-CO-MoS 2 Characterization of Nanomaterials

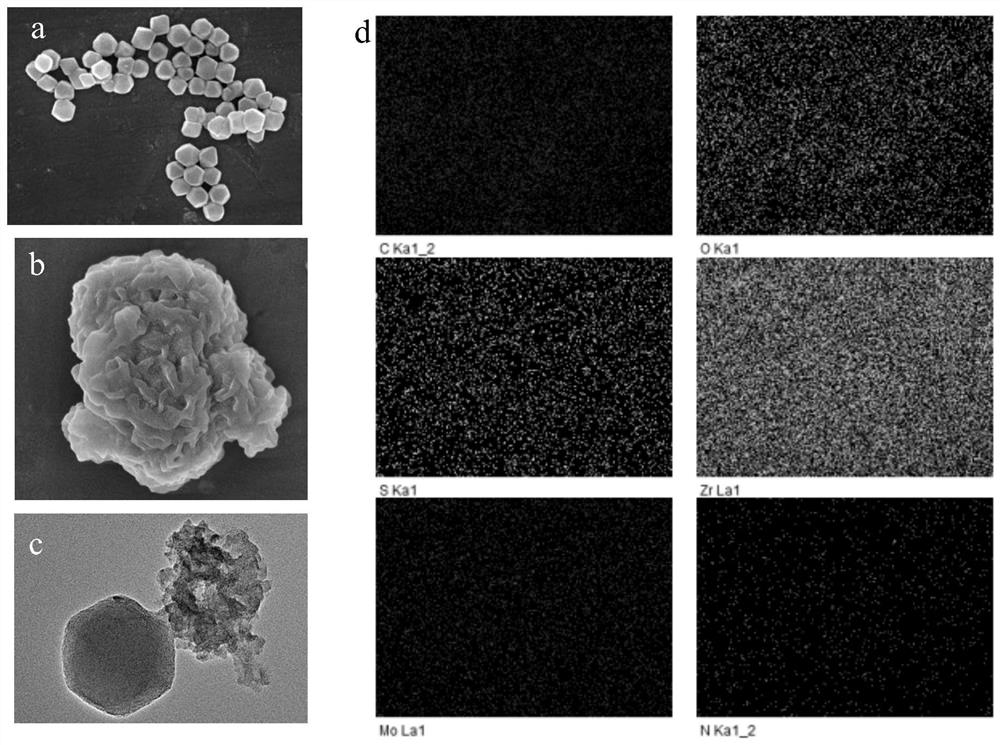

[0039] (1) Electron microscope analysis (SEM, TEM) and energy dispersive spectrometer (EDS) elemental analysis

[0040] Scanning electron microscopy (JSM7500F) and transmission electron microscopy (JEM2100) were used to analyze the UIO-66-NH-CO-MoS prepared in Example 1 2 Nanomaterials were observed and analyzed for their morphology, and the results are shown in the attached figure 1 :

[0041] figure 1 a is UIO-66-NH 2 SEM photos of the morphology, it can be observed that UIO-66-NH 2 octahedral crystallite structure. figure 1 b is MoS 2 SEM photos of the morphology, it can be observed that MoS 2 similar spherical microcrystalline structure. figure 1 c is UIO-66-NH-CO-MoS 2 The transmission scanning electron micrograph of UIO-66-NH can be observed 2 with MoS 2 linked by chemical bonds. figure 1 d is UIO-66-NH-CO-MoS 2 The elemental analysis shows the existence of the corresponding key elemen...

Embodiment 3

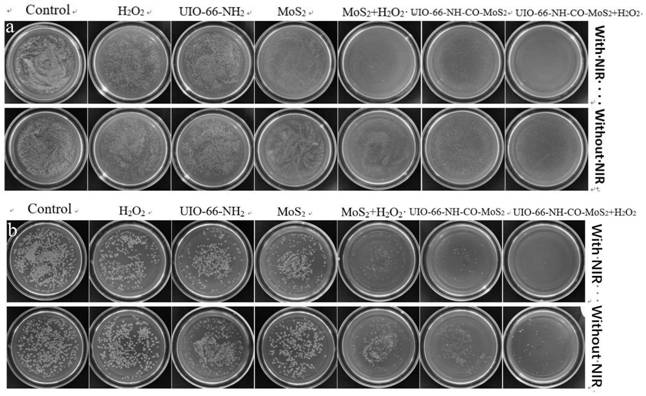

[0048] Example 3, UIO-66-NH-CO-MoS 2 Antibacterial experiment of nanomaterials

[0049] 1) Preparation of primary seed liquid: take 100 μL each of Staphylococcus aureus (ATCC 6538) and Escherichia coli (ATCC 8739) frozen in the laboratory, respectively, in 100 mL LB liquid medium (Haibo Biological), and shake at constant temperature for 13 hours (37°C, 100rpm) to obtain the primary seed solution;

[0050] 2) Preparation of the secondary seed liquid: 100 μL of the primary seed liquid obtained in 1) was respectively transferred to a new 100 mL LB liquid medium to obtain the secondary seed liquid;

[0051] 3) Preparation of antibacterial mother solution: Weigh an appropriate amount of UIO-66-NH 2 、MoS 2 、H 2 o 2 、MoS 2 +H 2 o 2 、UIO-66-NH-CO-MoS 2 and UIO-66-NH-CO-MoS 2 +H 2 o 2 Add respectively in the secondary seed liquid obtained in 2), the material concentration is 20 μ g / mL, H 2 o 2 The concentration is 2mmol / L, after irradiating with 808nm laser lamp (0.5W) fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com