A method for preparing flue gas desulfurization powder adsorbent by using liquid and solid waste

A technology of desulfurization powder and adsorbent, which is applied in the field of flue gas desulfurization, can solve the problems of classification and recovery of metal elements, difficulty in purification, damage to acid-base balance of water quality, metal pollution, etc., and achieve improved catalytic reaction rate, complete micropores, enlarged The effect of desulfurization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

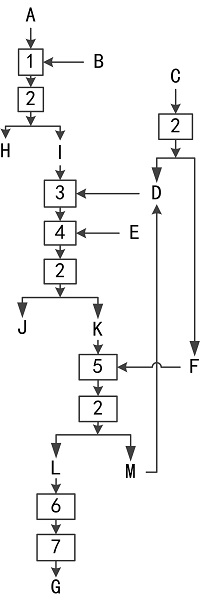

Image

Examples

Embodiment 1

[0025] Raw material: copper electrolysis wastewater 1, of which Cu 2+ The concentration is 25.8g / L, Ni 2+ The concentration is 11.4g / L, Fe 3+ The concentration is 8.3g / L, H 2 SO 4 The concentration is 179.6g / L; the main components of depotassium fume ash are manganese 30.12wt%, zinc 12.35wt%, iron 3.90wt%, oxygen 30.79wt%, silicon 15.71wt%, others 7.13wt%; calcium carbide slag slurry, moisture 42.4 wt%, calcium hydroxide 55.84wt%, other 1.76wt%.

[0026](1) Liquid-solid separation of calcium carbide slag slurry with a centrifuge to obtain lime milk and calcium carbide slag; (2) Under the condition of continuous stirring at a stirring speed of 300 rpm, 1000 g of copper electrolysis wastewater was added to the reactor and heated to 60 °C, Then slowly add 100g of 120-mesh depotassium soot, and carry out the acidolysis reaction for 1.0h, then centrifuge and wash to obtain acidolysis residue and sulfate solution; (3) Under the condition of continuous stirring at a stirring spee...

Embodiment 2

[0030] Raw materials: the same as the depotassium soot and calcium carbide slag slurry described in the above embodiment; copper electrolysis wastewater 2, wherein Cu 2+ The concentration is 48.7g / L, Ni 2+ The concentration is 18.9g / L, Fe 3+ The concentration is 4.2g / L, H 2 SO 4 The concentration is 247.4g / L.

[0031] (1) Liquid-solid separation of calcium carbide slag slurry with a centrifuge to obtain lime milk and calcium carbide slag; (2) Under the condition of continuous stirring at a stirring speed of 500 rpm, 1000 g of copper electrolysis wastewater was added to the reactor and heated to 70 °C, Then slowly add 300g of 120-mesh depotassium soot, and carry out acid hydrolysis for 3.0h, centrifuge and wash to obtain acidolysis residue and sulfate solution; (3) Under the condition of continuous stirring at a stirring speed of 1000rpm, go to step (2) To the separated sulfate solution, the lime milk obtained in step (1) was added to adjust the pH value of the solution to ...

Embodiment 3

[0035] Raw materials: the same as the copper electrolysis wastewater 2, the ferromanganese desulfurizer saturated sulfur-containing waste residue, and the calcium carbide slag slurry described in the above-mentioned embodiment and comparative example.

[0036] (1) Liquid-solid separation of calcium carbide slag slurry with a centrifuge to obtain lime milk and calcium carbide slag; (2) Under the condition of continuous stirring at a stirring speed of 400 rpm, 1000 g of copper electrolysis wastewater was added to the reactor and heated to 80 °C, Then slowly add 200g of 80-mesh ferromanganese desulfurizer saturated sulfur-containing waste residue, and after acidolysis for 2.0h, centrifuge and wash to obtain acidolysis residue and sulfate solution; (3) Under the condition of continuous stirring at a stirring speed of 750rpm, to In the sulfate solution obtained in step (2), the lime milk obtained in step (1) was added to adjust the pH value of the solution to 10, the precipitation r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com