Perovskite solar cell based on halogen-free lead source and preparation method of perovskite solar cell

A solar cell and perovskite technology, applied in the field of solar cells, can solve problems such as difficult preparation, and achieve the effects of good film formation, low defect density and large grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

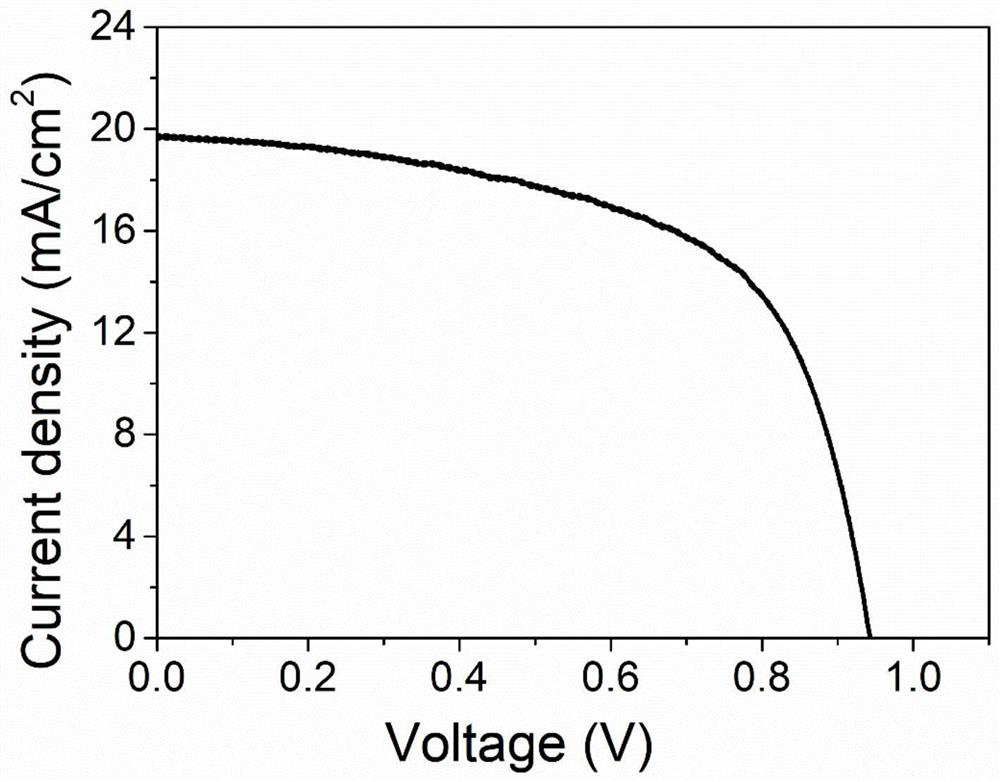

Embodiment 1

[0023] A method for preparing a perovskite solar cell based on a non-halogen lead source, comprising the following steps:

[0024] (1) Substrate cleaning: clean the surface dirt of the transparent conductive substrate FTO with a detergent. Then place it in deionized water, acetone, isopropanol and ethanol in order to ultrasonically clean it for 10-15 minutes, and finally soak it in ethanol solution for storage. Before use, dry it with nitrogen and clean it with an ultraviolet ozone machine for 15-30 minutes.

[0025] (2) Electron transport layer preparation: commercial 15% SnO 2 The colloidal aqueous solution and deionized water were prepared at a mass ratio of 1:5 to make 2.5% SnO 2 Colloidal solution, stirred for one hour and set aside. Pipette 90 μl of SnO 2 The precursor solution was evenly dropped on the treated FTO transparent conductive substrate. The spin-coating conditions were low speed 500r / min for 3s, high speed 3000r / min for 30s, and annealing on a heating plat...

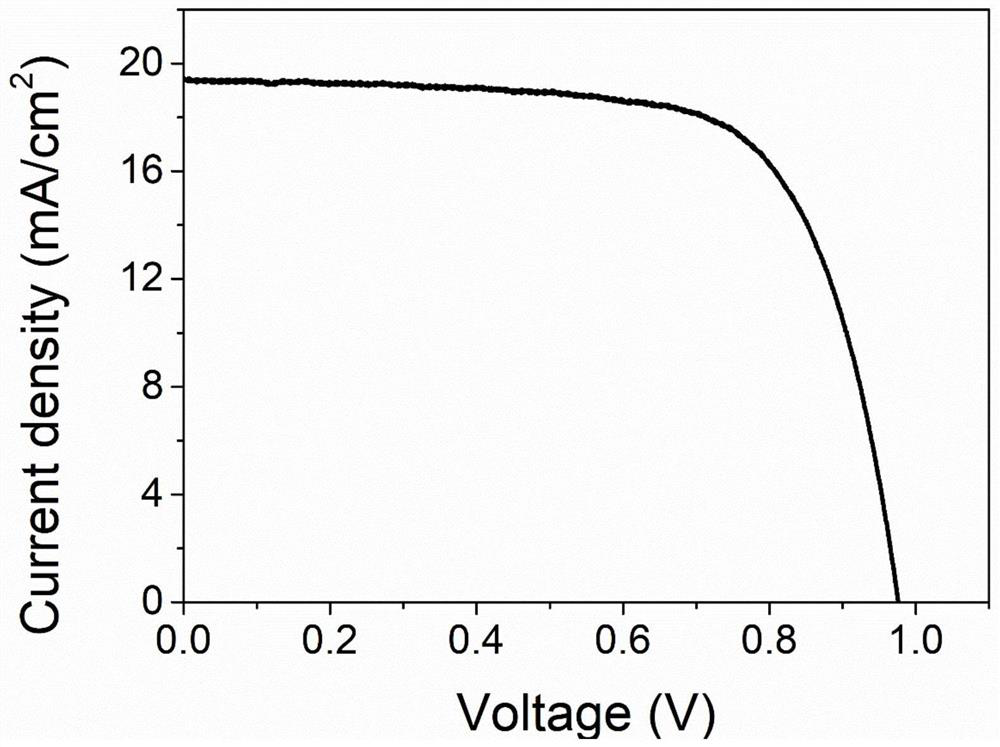

Embodiment 2

[0031] A method for preparing a perovskite solar cell based on a non-halogen lead source, the difference between this embodiment and embodiment 1 is: the preparation of the perovskite light-absorbing layer: Pb(SCN) 2 : Pb(Ac) 2 A non-halogenated lead source mixed in a molar ratio of 1:3 with CH 3 NH 3 I is dissolved in the mixed solution of dimethylformamide (DMF) and dimethyl sulfoxide (DMSO) at a molar ratio of 1:3 (V 1 :V 2 =4:1), stirred overnight at 70°C, and filtered before use. Use a pipette gun to draw 50 μl of the filtered perovskite precursor solution, and drop it evenly on the SnO 2On the substrate of the electron transport layer, spin coat with a coater at a speed of 5000r / min for 30s, and add ethyl acetate dropwise evenly and rapidly at the penultimate 15s to 5s after the spin coating. Then transfer the perovskite mesophase film to a hot stage for annealing, pre-anneal at 70°C for 3 minutes, and anneal at 100°C for 15 minutes to obtain the perovskite light-ab...

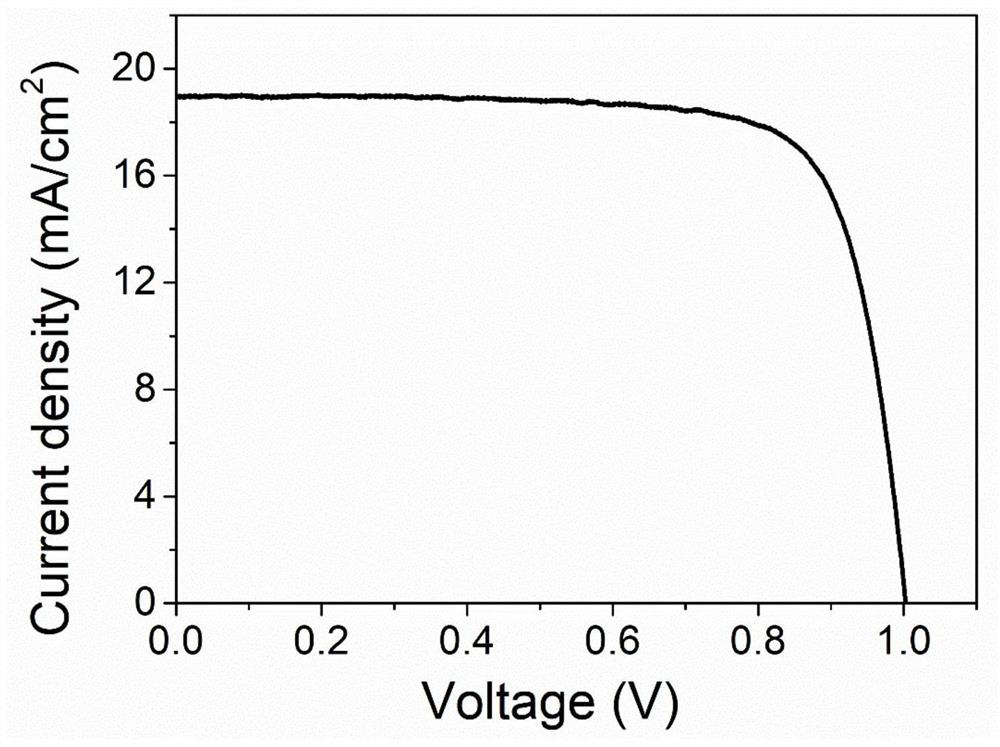

Embodiment 3

[0034] A method for preparing a perovskite solar cell based on a non-halogen lead source, the difference between this embodiment and embodiment 1 is:

[0035] Electron transport layer preparation: Commercial 15% SnO 2 Colloidal aqueous solution and deionized water were prepared to make 2% SnO 2 Colloidal solution, stirred for one hour and set aside. Pipette 100 μl of SnO 2 The precursor solution was evenly dropped on the treated FTO transparent conductive substrate. The spin-coating conditions were low speed 500r / min for 3s, high speed 3000r / min for 30s, and annealing on a heating plate at 60°C for 30min to obtain SnO 2 electron transport layer.

[0036] Preparation of perovskite light-absorbing layer: Pb(SCN) 2 : Pb(Ac) 2 A non-halogenated lead source mixed in a molar ratio of 1:1 with CH 3 NH 3 I is dissolved in the mixed solution of dimethylformamide (DMF) and dimethyl sulfoxide (DMSO) according to molar ratio 1:3.2 (V 1 :V 2 =9:1), stirred overnight at 70°C, and f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap