Preparation method and application of high-activity crystal face co-exposed anatase type TiO2 nanocrystal

An anatase-type, nanocrystalline technology, applied in chemical instruments and methods, titanium oxide/hydroxide, titanium dioxide, etc., can solve the problems of difficult to control the hydrolysis rate, difficult to mass production, high price, etc. The effect of UV performance, short production cycle and low synthesis cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Preparation of tetrabutyrate colloidal solution: 20 ml of absolute anhydrous ethanol in three reactions is drawn by pipettes, placed on a magnetic stirrer, and 20 ml of titanate titanate is added dropwise under stirring. (0.0584 mol, mass fraction 99.7%), 2 ml of egg white and 2 ml polyethylene glycol 600, mixed mixed, prepared 3 parts of a tetrabutyate colloid solution in a transparent titanate tetrabutyrate );

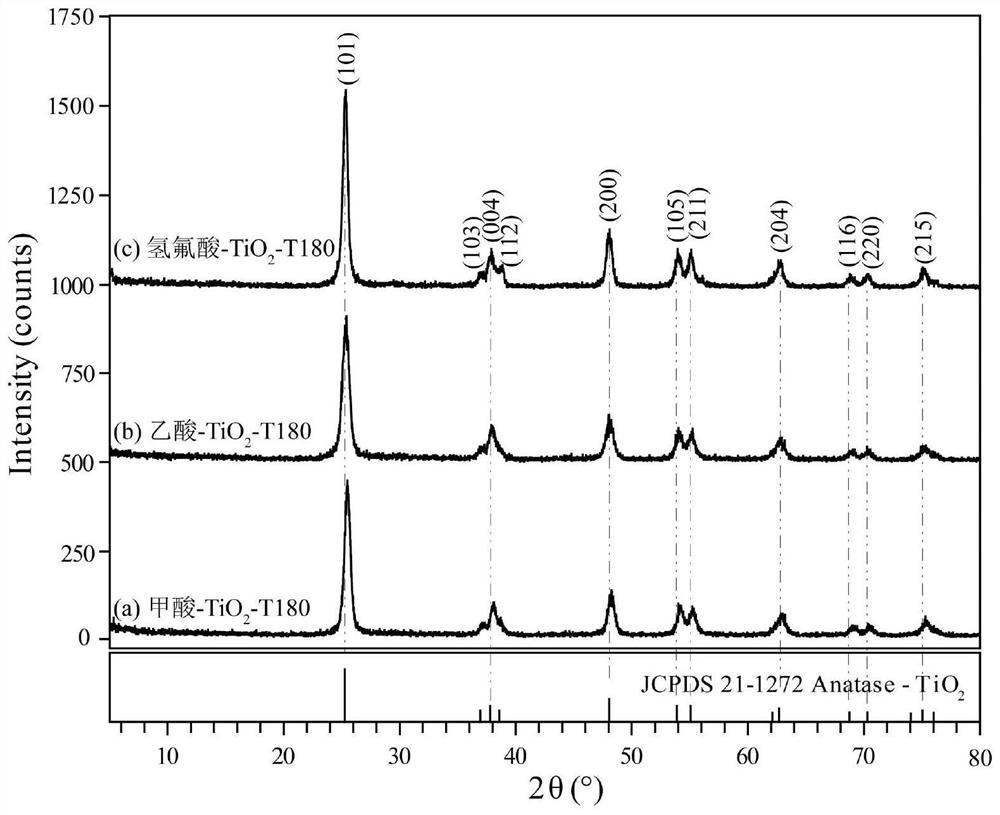

[0038] (2) Preparation of titanium dioxide hydrate: 3 parts of the tetrabutyrate colloidal solution prepared to step (1), add 2.0 ml of formic acid (0.0466 mol, mass fraction of 88.0%), acetic acid (0.0349 mol, mass fraction), respectively. 99.8%) and HF solution (0.0452 mol, mass fraction 40%), mixed with mixed, sealed, placed in a constant temperature blast drying tank at a set temperature of 180 ° C, heat reactive for 24 h, cooling to room temperature, will be taken out, The resulting product was filtered with a circulating water type vacuum pump and washed...

Embodiment 2

[0060] (1) Preparation of tetrabutyrate colloidal solution: 20 ml of absolute anhydrous ethanol in three reactions is drawn by pipettes, placed on a magnetic stirrer, and 20 ml of titanate titanate is added dropwise under stirring. (0.0584 mol, mass fraction 99.7%), 3 ml of egg white and 3 ml polyethylene glycol 600, mixed mixed, mixed mixed titanate colloidal solution (3 parts of the tetrabutyrate colloidal solution for the same method );

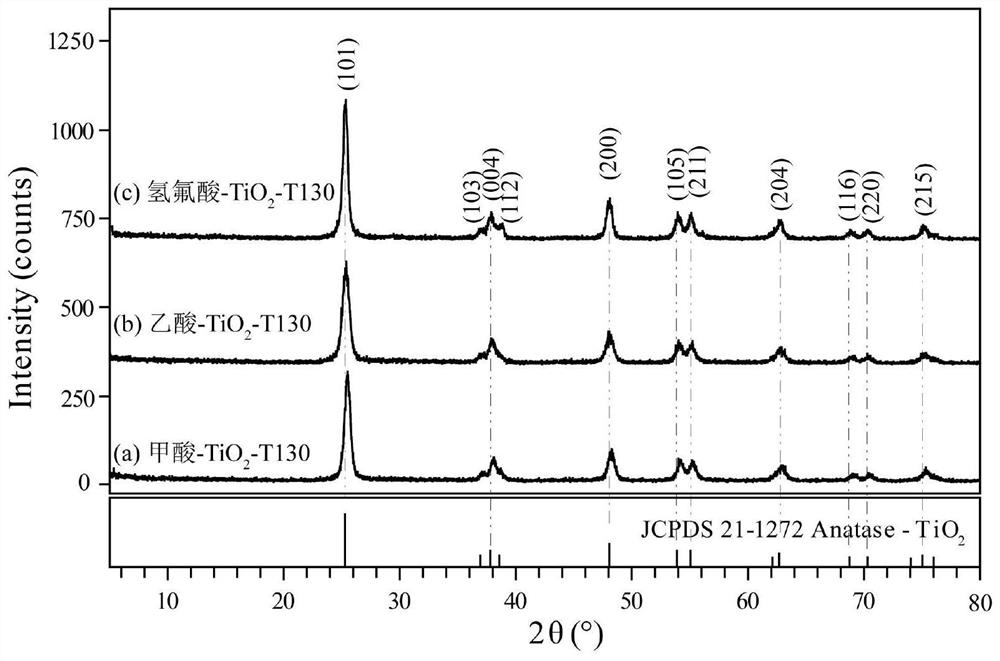

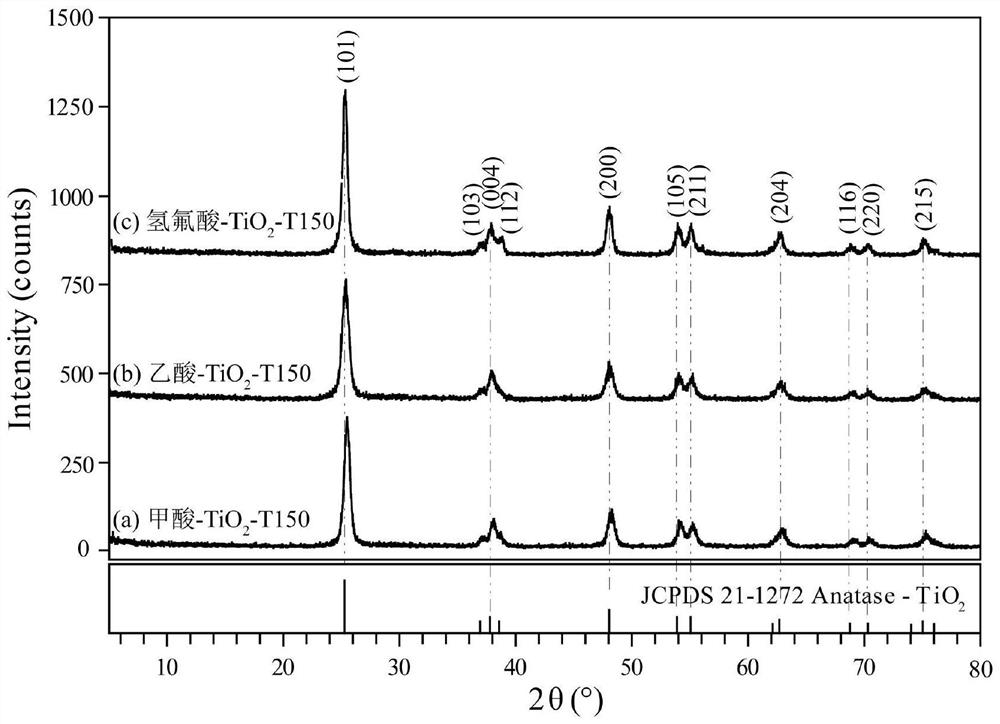

[0061] (2) Preparation of a titanium dioxide hydrate: 3 parts of the tetrabutyrate colloidal solution prepared from step (1), adding 1.0 ml of formic acid (0.0233 mol, mass fraction 88.0%), acetic acid (0.0175 mol, mass fraction 99.8%) and HF solution (0.0276 mol, mass fraction 40%), mixed with mixed, sealed, placed in a constant temperature blast drying tank at a set temperature of 150 ° C, heat reactive for 6 h, cooling to room temperature, will be removed The resulting product was filtered with a circulating water type vacuum pump and washe...

Embodiment 3

[0071] (1) Tetretic acid tetrabutyrate colloidal solution: 20 ml of absolute ethanol in three reactions was taken from the pipette, and 30 ml of tetrabutyl titanate was added dropwise on a magnetic agitator. (0.0876 mol, mass fraction 99.7%), 5 ml of egg white and 5 ml polyethylene glycol 600, mixed mixed, prepared 3 parts of a titanate tetrabutyl colloid solution in a transparent titanate tetrabutyrate );

[0072] (2) Preparation of a titanium dioxide hydrate: 7.5 ml of formic acid (0.1749 mol, mass fraction 88.0%), acetic acid (0.1309 mol, mass fraction) is added dropwise to the step (1). 99.8%) and HF solution (0.1694 mol, mass fraction 40%), mixed with mixed, sealed, placed in a constant temperature blast drying tank at a set temperature of 150 ° C, a solvent thermal reaction for 6 h, cooled to room temperature, will be taken out, The resulting product was filtered with a circulating water type vacuum pump and washed with a large amount of distilled water until the filtrate wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com