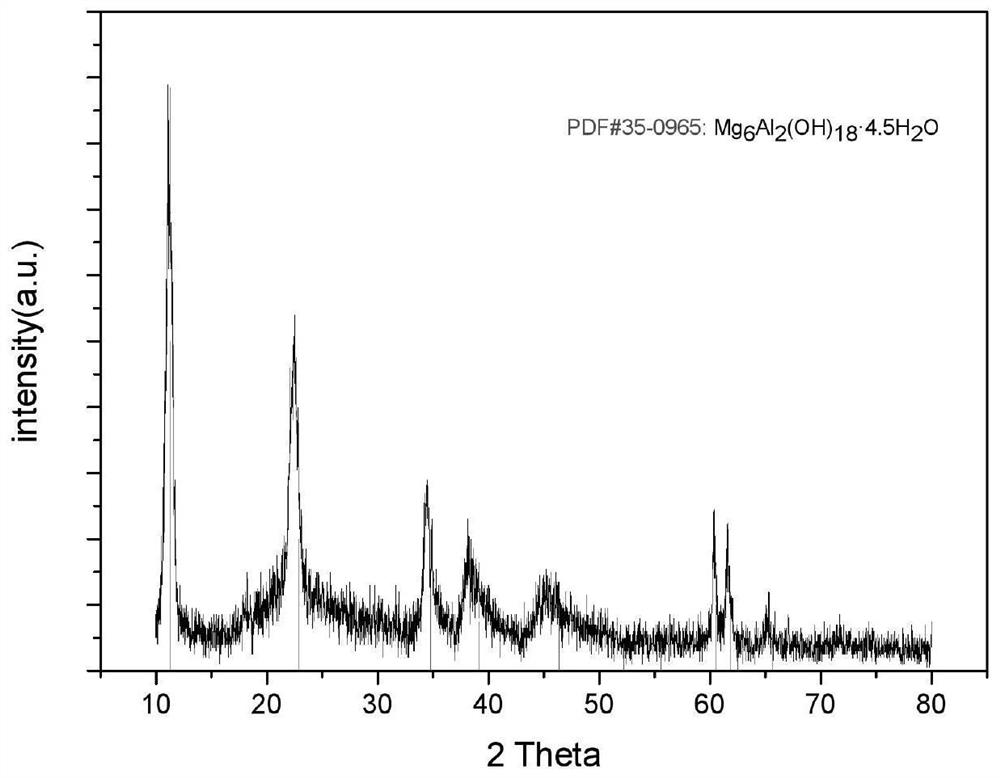

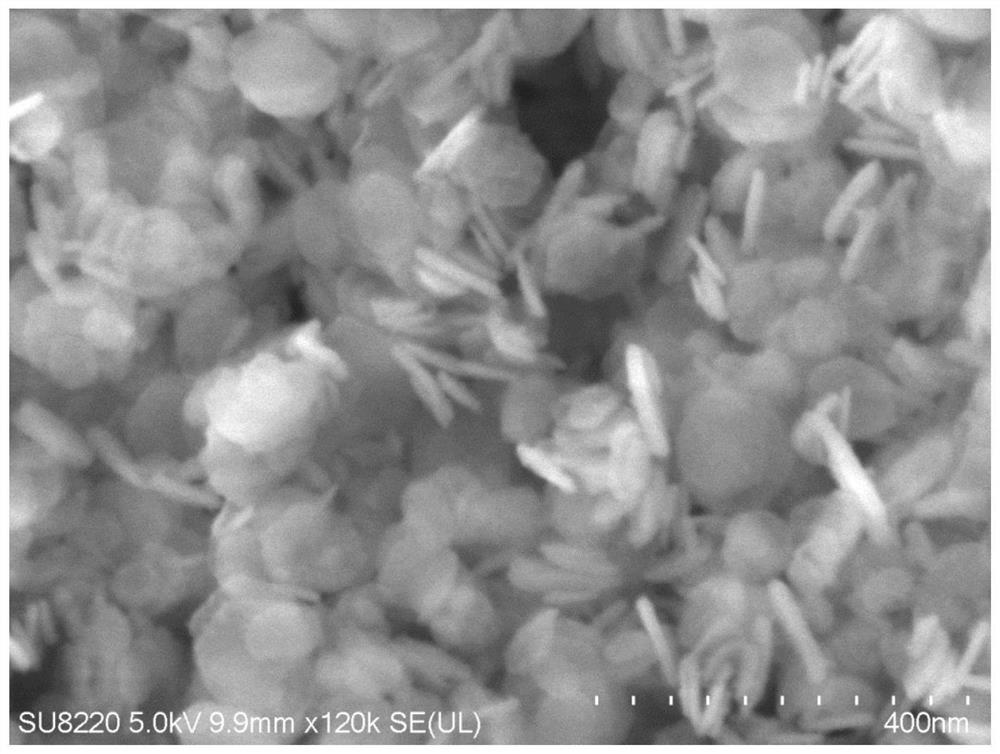

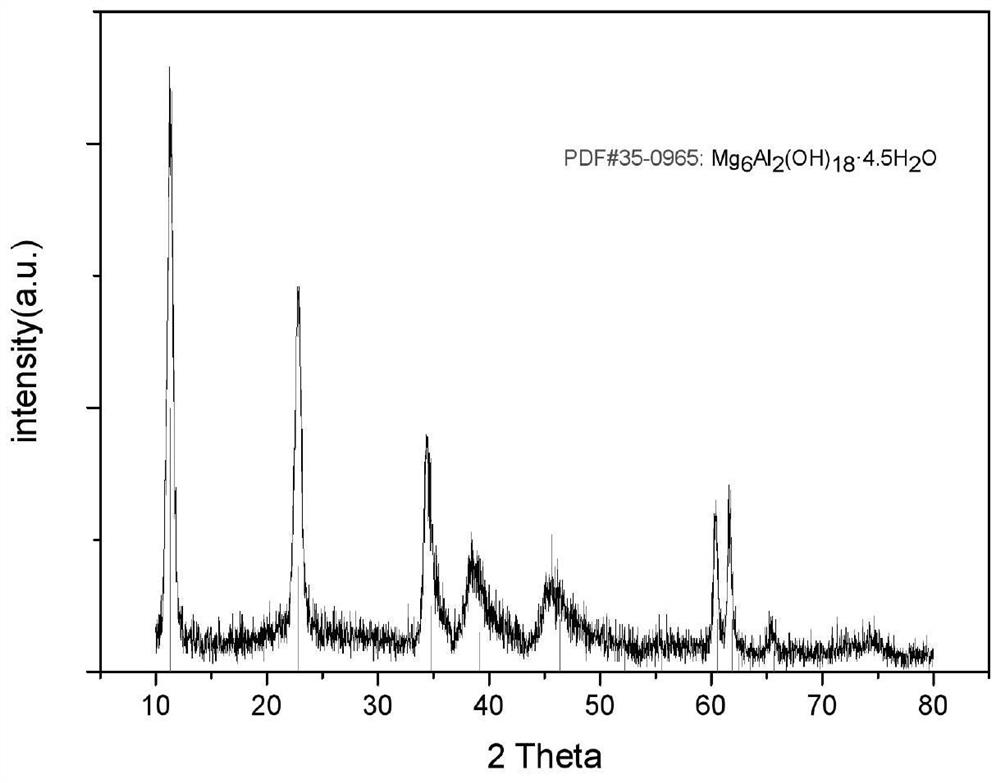

a mg 6 al 2 (oh) 18 4.5h 2 oNanosheets and their preparation methods and applications

A nano-sheet and nano-silica technology, applied in nanotechnology, chemical instruments and methods, aluminum compounds, etc., can solve the problems of polluting ion exchange resins, easy agglomeration, pipeline corrosion, etc., and avoid purification steps and high-speed centrifugation , good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] a Mg 6 Al 2 (OH) 18 ·4.5H 2 The special preparation method of O nanosheets includes the following steps:

[0035] Take 60mL, 0.30mol / LMgCl 2 and 60mL, 0.10mol / LAlCl 3 The solution was mixed evenly in equal volume, and the Mg and Al molar ratio was 3:1. The solution was placed in a 200 mL constant pressure dropping funnel, and then added dropwise to the vigorously stirred 0.50 mol / L sodium hydroxide solution. When the pH of the reaction solution was 10.8, the obtained A precipitate was washed once, re-dispersed in 30 mL of water containing 10 wt% ethylene glycol, and heat-treated at 100 °C for 4 h in a microwave hydrothermal parallel synthesizer to obtain sol material B, and then the obtained sol was The material B was transferred to a small stainless steel hydrothermal reactor lined with PTFE, and reacted at 100 °C for 16 h to obtain the sol material C, and then put the sol material C in the nano-silica microemulsion, and the pH was kept at 10, After heating at 70...

Embodiment 2

[0038] a Mg 6 Al 2 (OH) 18 ·4.5H 2 The special preparation method of O nanosheets includes the following steps:

[0039] Take 60mL, 0.30mol / L Mg(NO 3 ) 2 and 60mL, 0.10mol / LAI ((NO 3 ) 3 The solution was mixed evenly in equal volume, and the Mg and Al molar ratio was 3:1. The solution was placed in a 200 mL constant pressure dropping funnel, and then added dropwise to the vigorously stirred 0.50 mol / L potassium hydroxide solution. When the pH of the reaction solution was 11.3, the obtained A precipitate was washed once, re-dispersed in 30 mL of water containing 10 wt% ethylene glycol, and heat-treated at 120 °C for 2 h in a microwave hydrothermal parallel synthesizer to obtain sol material B, and then the obtained sol was The material B was transferred to a small stainless steel hydrothermal reactor lined with PTFE, and reacted at 120 ° C for 4 hours to obtain the sol material C, and then put the sol material C in the nano-silica microemulsion, and the pH was kept at 11...

Embodiment 3

[0042] a Mg 6 Al 2 (OH) 18 ·4.5H 2 The special preparation method of O nanosheets includes the following steps:

[0043] Take 60mL, 0.15mol / LMgCl 2 and 60mL, 0.05mol / LAlCl 3 The solution was mixed evenly in equal volume, and the Mg and Al molar ratio was 3:1. The solution was placed in a 200 mL constant pressure dropping funnel, and then added dropwise to the vigorously stirred 0.25 mol / L sodium hydroxide solution, and added dropwise all the time. When the pH of the reaction solution was 10.7, the obtained A precipitate was washed once, re-dispersed in 30 mL of water containing 10 wt% ethylene glycol, and heat-treated at 100 °C for 4 h in a microwave hydrothermal parallel synthesizer to obtain sol material B, and then the obtained sol was The material B was transferred to a small stainless steel hydrothermal reactor lined with PTFE, and reacted at 120 °C for 4 hours to obtain the sol material C, and then put the sol material C in the preparation of nano-silica microemulsi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com