Multifunctional ultrafiltration membrane, and preparation method and application thereof

An ultrafiltration membrane, a multi-functional technology, applied in ultrafiltration, chemical instruments and methods, membranes, etc., can solve the problems of decreased membrane flux, membrane structure damage, and reduced membrane service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

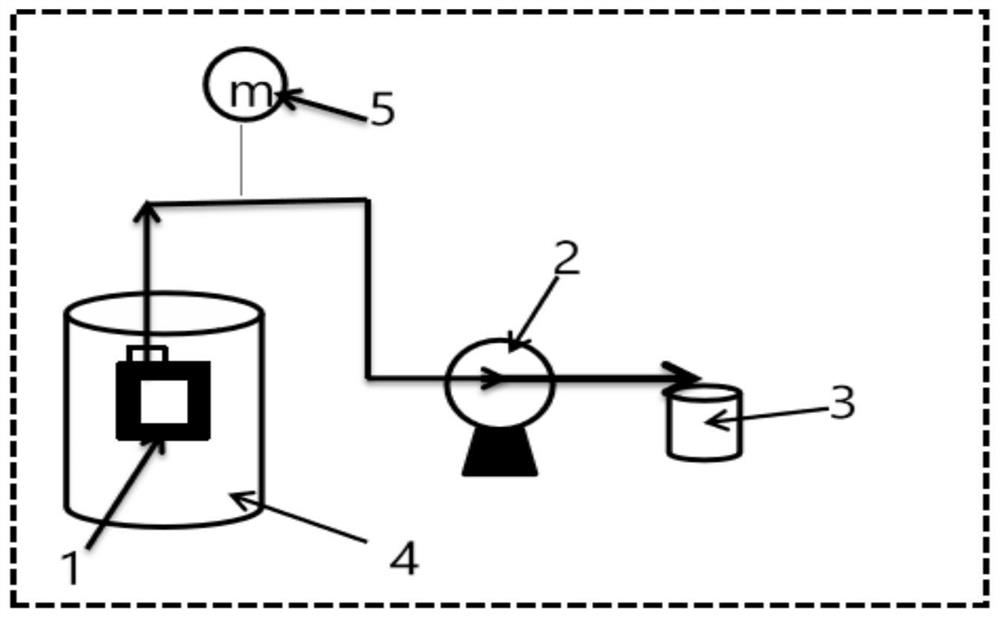

Image

Examples

Embodiment 1

[0027] The invention provides a preparation method of a multifunctional ultrafiltration membrane, comprising:

[0028] (1) The pyrolysis experiment was carried out in a tubular pyrolysis furnace. Take 2 grams of wood chips and aluminum slag and mix them evenly in a ratio of 1:1, put them in a quartz boat, and use a push rod to put the quartz boat into a 60mm diameter In the quartz tube reactor, the quartz tube reactor is placed in a suitable position of the pyrolysis furnace so that the quartz boat is in the constant temperature heating zone, and nitrogen gas is introduced as a protective gas. Rise to the specified temperature (700°C) in a tubular pyrolysis furnace at a rate of 10°C for 30 minutes, then cool to room temperature, take out the biochar after complete cooling, and transfer it to a plastic bag for storage.

[0029] (2) Grind the biochar material to 600 mesh in a ball mill for later use. The polysulfone was dried in a vacuum oven for 10 h, and 18 g of dry polysulfo...

Embodiment 2

[0033] The biochar preparation method is the same as in Example 1.

[0034] The polyethersulfone was dried in a vacuum oven for 10 h, and 18 g of dry polyethersulfone, 1.5 g of biochar material, and 0.5 g of polyethylene glycol were dissolved in 80 g of organic solvent N,N-2-methylacetamide. Ultrasound for 1-3 hours, and dissolve with magnetic stirring at a temperature of 60°C until the casting solution is transparent gray-black, then let stand to remove bubbles. Using the phase inversion method, the above-mentioned cast film liquid phase is transformed into a film.

[0035] The prepared multifunctional ultrafiltration membrane was installed in a pressure filtration experimental device to test the removal rate of dyes. Taking methyl orange as an example, the removal rate of polyethersulfone membrane to methyl orange was 2 .

[0036] The sewage treatment test method is the same as in Example 1. Influent COD is 377.5, ammonia nitrogen is 28.06, COD and ammonia nitrogen are red...

Embodiment 3

[0038] The biochar preparation method is the same as in Example 1.

[0039] The polyvinylidene fluoride was dried in a vacuum oven for 10 h, and 15.0 g of dry polyvinylidene fluoride, 2.0 g of biochar material, and 1.0 g of polymethyl methacrylate were dissolved in 82.0 g of organic solvent nitrogen methyl pyrrolidone. Ultrasound for 1-3 hours, stir and dissolve at 50°C with magnetic force until the casting solution is transparent gray-black, then let stand to defoam. Using the phase inversion method, the above-mentioned cast film liquid phase is transformed into a film.

[0040] The prepared multifunctional ultrafiltration membrane was installed in a pressure filtration experimental device to test the removal rate of dyes. Taking methyl orange as an example, the removal rate of pure polyvinylidene fluoride membrane to methyl orange was 2 .

[0041] The sewage treatment test method is the same as that in Example 1. Influent COD is 377.5, ammonia nitrogen is 28.06, COD and am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com