Ultralow-oxygen-content three-dimensional nitrogen-doped graphene aerogel and preparation method thereof

A nitrogen-doped graphene, graphene aerogel technology, applied in graphene, chemical instruments and methods, inorganic chemistry, etc. Completely removed, the types of nitrogen-containing functional groups are not adjustable, etc., to achieve the effect of adjustable three-dimensional porous structure, low equipment and raw material requirements, and fewer surface defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

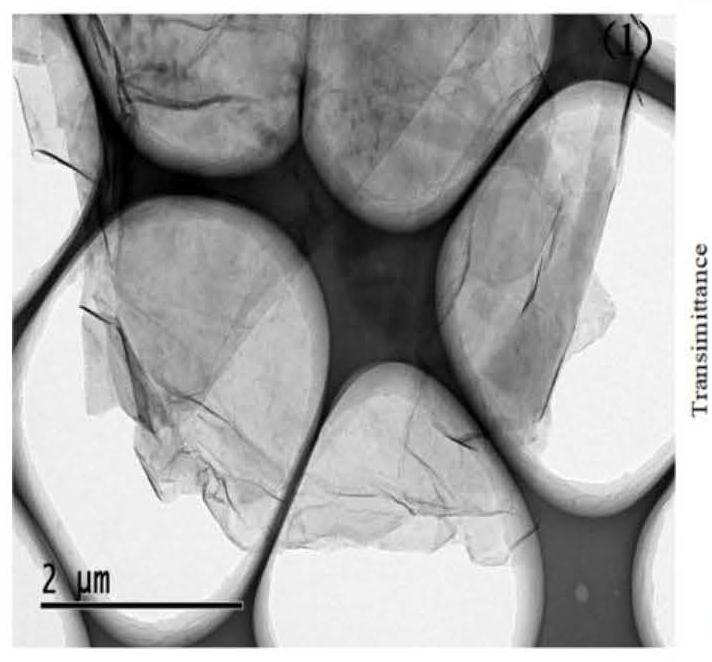

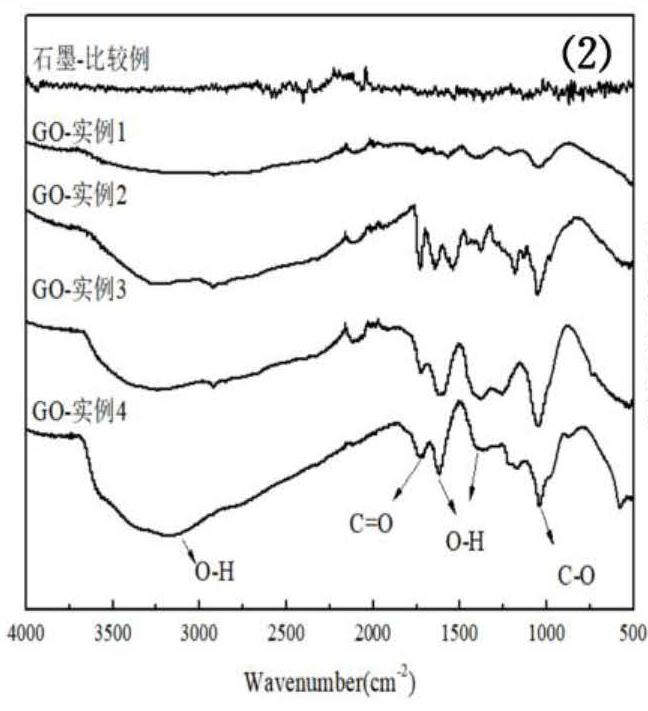

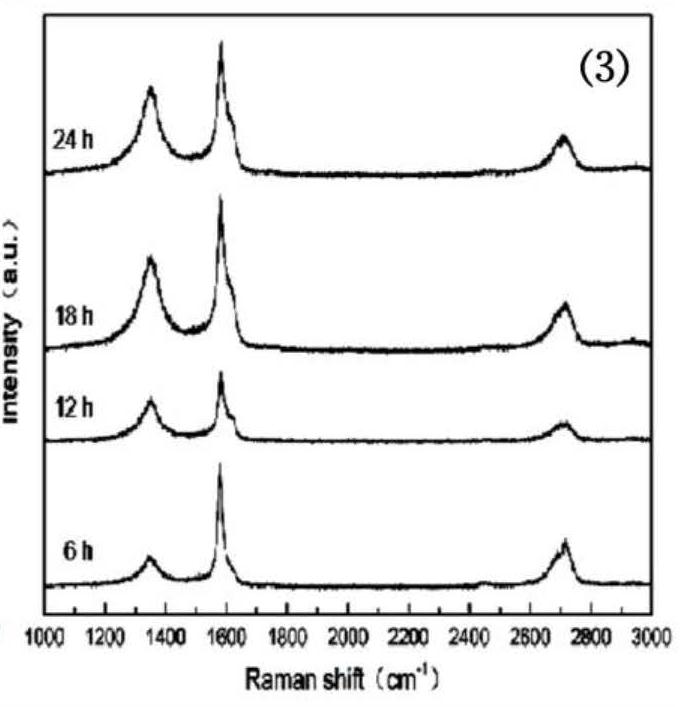

Image

Examples

preparation example Construction

[0080] 3, the third object of the present invention is to provide a kind of preparation method of ultra-low oxygen content three-dimensional nitrogen-doped graphene airgel, the preparation method of graphene airgel comprises the steps:

[0081] Step 1): Graphene oxide is used as a precursor to form an aqueous dispersion, and nitrogen sources, reducing agents, and amine-based small-molecule organic compounds are added in sequence, and a cylindrical low-oxygen three-dimensional nitrogen-doped graphene water is prepared by a one-step hydrothermal reduction method. Gel, after freeze-drying, a three-dimensional nitrogen-doped graphene airgel intermediate with low oxygen content is obtained;

[0082] A lightweight three-dimensional nitrogen-doped graphene hydrogel with high nitrogen-doped content and high proportion of pyrrole-type nitrogen was prepared by hydrothermal reduction method, and then the airgel intermediate was obtained by dialysis to desalt and freeze-dried. The nitrogen...

Embodiment 1

[0097] 1.1 Preparation of low carboxyl group and high hydroxylation few-layer graphene oxide precursor aqueous solution

[0098] Step 1-1): using natural graphite plate as anode, metal titanium mesh as cathode, ammonium sulfate as electrolyte and intercalation agent, sodium dodecylsulfonate as auxiliary additive, and water as solvent to prepare electrolyte;

[0099] Step 1-2): Prepare low-carboxyl and high-hydroxylation few-layer graphene oxide by electrochemical intercalation and stripping the anode method. The specific steps are as follows: cut the thickness to 2mm and the area to 15cm 2 The natural graphite plate as the anode is connected to the positive pole of the 20V DC power supply, and the titanium mesh cathode with more than twice the area of the anode is connected to the negative pole of the 20V DC power supply to form an electrode pair; a 0.1mol / L ammonium sulfate aqueous solution is prepared and added to the electrolytic cell for electrolysis. The liquid volume a...

Embodiment 2

[0111] 2.1 Preparation of low carboxyl group and high hydroxylation few-layer graphene oxide precursor aqueous solution:

[0112] Step 1-1): Using a dense crystalline graphite plate as an anode, a metal titanium mesh as a cathode, ammonium sulfate as an electrolyte and an intercalation agent, sodium dodecylsulfonate as an auxiliary additive, and water as a solvent to prepare an electrolyte;

[0113] Step 1-2): Using electrochemical intercalation exfoliation anodic oxidation to prepare low-carboxyl and high-hydroxylation few-layer graphene oxide, the specific steps are as follows: cut a thickness of 2mm and an area of 15cm 2 The scaly graphite plate is used as the anode and connected to the positive pole of the 20V DC power supply, and the titanium mesh cathode with more than twice the area of the anode is connected to the negative pole of the 20V DC power supply to form an electrode pair; a 0.2mol / L ammonium sulfate aqueous solution is prepared and added to the electrolytic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com