Low-load Pt/C catalyst hydrogen diffusion anode and preparation method and application thereof

A supported catalyst, low-load technology, applied in the field of electrochemistry, can solve the problems of polluted electrolyte and cathode products, low mechanical strength of lead-silver anode, increased production energy consumption, etc., to achieve high hydrogen oxidation reaction catalytic effect, excellent hydrogen The effect of reducing oxidation activity and unit power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

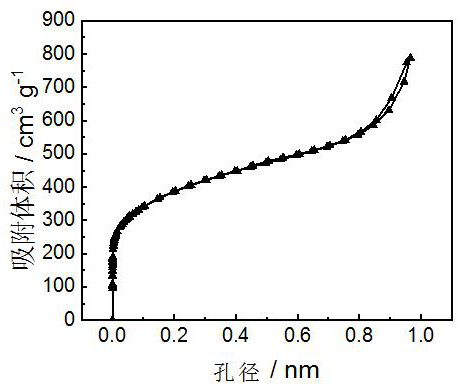

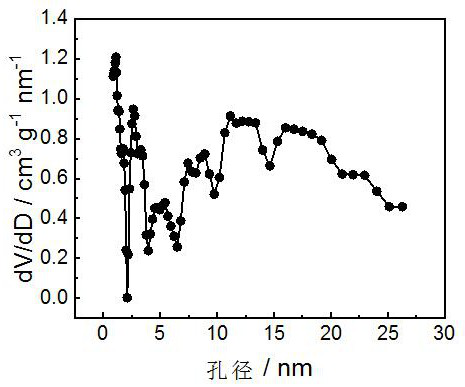

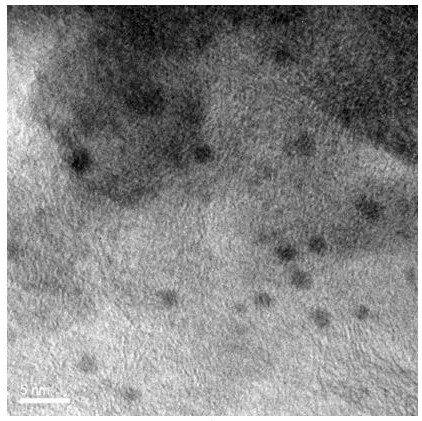

[0050] 1. Preparation of low-loaded Pt / C catalyst

[0051] 1. Use BP-2000 nano-carbon as raw material, mix it with sodium hydroxide at a mass ratio of 10:2, and grind it mechanically for 10 minutes to make it fully mixed; put the obtained powder in a tube furnace, and heat it at 10 ° under Ar atmosphere The heating rate of C / min is gradually increased to 800 ° C for 1 hour, and then cooled to room temperature with the furnace;

[0052] 2. Suction filter the obtained product with water, wash it, and dry it in an oven at 70°C for 12 hours to obtain the carbon carrier.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com