Stable formaldehyde-free photosensitive microcapsule and preparation method thereof

A microcapsule and stable technology, applied in the field of stable formaldehyde-free photosensitive microcapsules and their preparation, can solve the problems of reduced protection ability, aging decomposition, low glass transition temperature, etc., and achieves good mechanical properties, good thermal stability, Prepare quick and easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] After the isocyanate-terminated polyurethane prepolymer with an average molecular weight of 5000 is completely dehydrated, weigh 100g and put it into a three-necked flask. After the siloxane is completely dehydrated, weigh 3.1 g and slowly add it dropwise, and react for several hours to obtain a wall material prepolymer.

[0032] After the wall material prepolymer has dropped to room temperature, weigh 3.2g of diarylethene and fully disperse it in 30g of 200# solvent oil, stir and raise the temperature to 170°C to completely melt the diarylene, then cool to room temperature, and then add UV 6g of absorbent, 25.3g of E51 epoxy resin, 21.5g of methyl tetrahydrophthalic anhydride, and 25g of wall material prepolymer are fully stirred evenly.

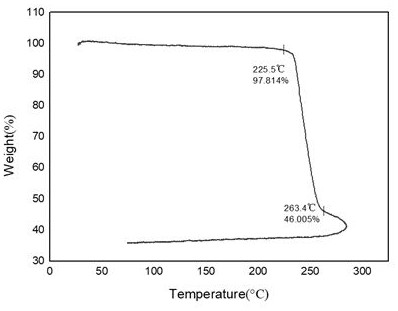

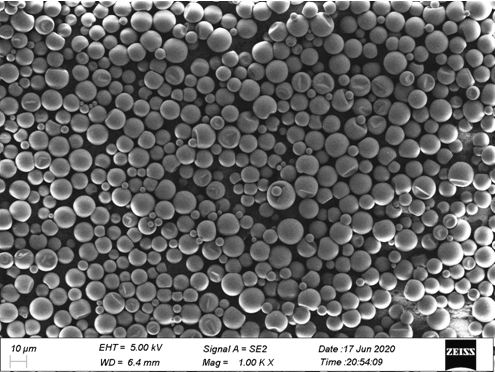

[0033]Add the above oil phase solution into the aqueous solution of styrene-maleic anhydride block copolymer and stir at a high speed to form an oil-in-water O / W emulsion. Slowly add 10 g of diethylenetriamine and a catalyst in the e...

Embodiment 2

[0036] After the isocyanate-terminated polyurethane prepolymer with an average molecular weight of 10,000 is completely dehydrated, weigh 200g and put it into a three-necked flask. After the siloxane is completely dehydrated, weigh 5.3 g and slowly add it dropwise, and react for several hours to obtain a wall material prepolymer.

[0037] After the wall material prepolymer has dropped to room temperature, weigh 1.6g of diarylene and fully disperse it in 20g of 200# solvent oil, stir and raise the temperature to 170°C to completely melt the diarylene, then cool to room temperature, and then add UV 1g of absorbent, 30.8g of E51 epoxy resin, 27.6g of methyl tetrahydrophthalic anhydride, and 30g of wall material prepolymer are fully stirred evenly.

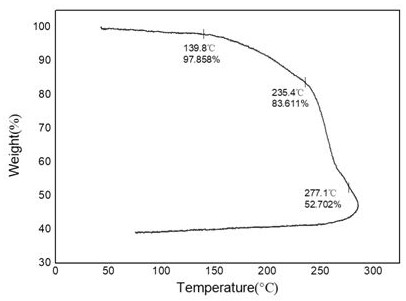

[0038] Add the above oil phase solution into the aqueous solution of styrene-maleic anhydride block copolymer and stir at a high speed to form an oil-in-water O / W emulsion. Slowly add ethylenediamine 8g and catalyst to the emulsion, t...

Embodiment 3

[0040] After the isocyanate-terminated polyurethane prepolymer with an average molecular weight of 2500 is completely dehydrated, weigh 100g and put it into a three-necked flask. After the siloxane is completely dehydrated, weigh 8.84 g and slowly add it dropwise, and react for several hours to obtain a wall material prepolymer.

[0041] After the wall material prepolymer has dropped to room temperature, weigh 1.6g of heterocyclic azobenzene and fully disperse it in 20g of 200# solvent oil, stir and raise the temperature to 150°C to completely melt the heterocyclic azobenzene, then cool to room temperature, and then Add 1g of UV absorber, 30.8g of E51 epoxy resin, 27.6g of methyl tetrahydrophthalic anhydride, and 30g of wall material prepolymer and stir well.

[0042] Add the above oil phase solution into the aqueous solution of styrene-maleic anhydride block copolymer and stir at high speed to form an oil-in-water O / W emulsion, slowly add 9g of diethylenetriamine, 1g of ethyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com