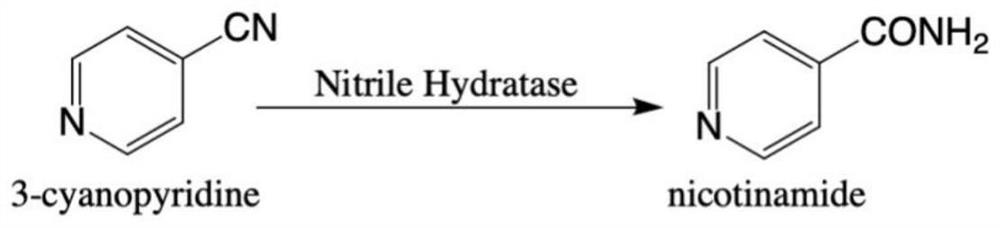

Recombinant nitrile hydratase and application thereof in preparation of nicotinamide by coupling ion exchange resin

An ion-exchange resin, nitrile hydratase technology, applied in the application, recombinant DNA technology, lyase and other directions, can solve the problems of limiting the application of nitrile hydratase catalyst, difficult product separation and purification process, slowing down of enzyme catalytic reaction speed, etc. The effect of improved substrate and product tolerance, mild conditions, and non-polluting energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

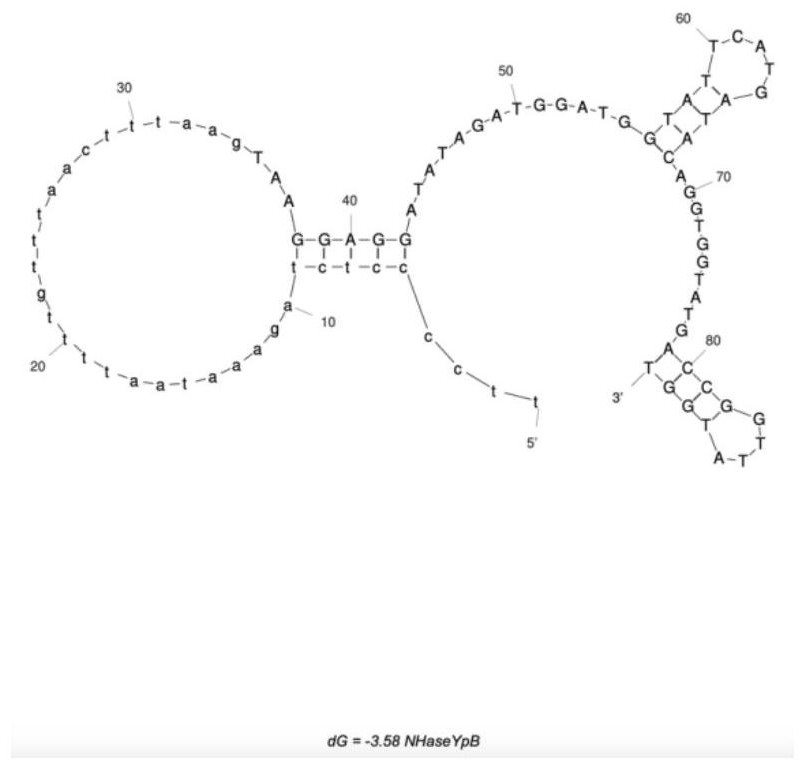

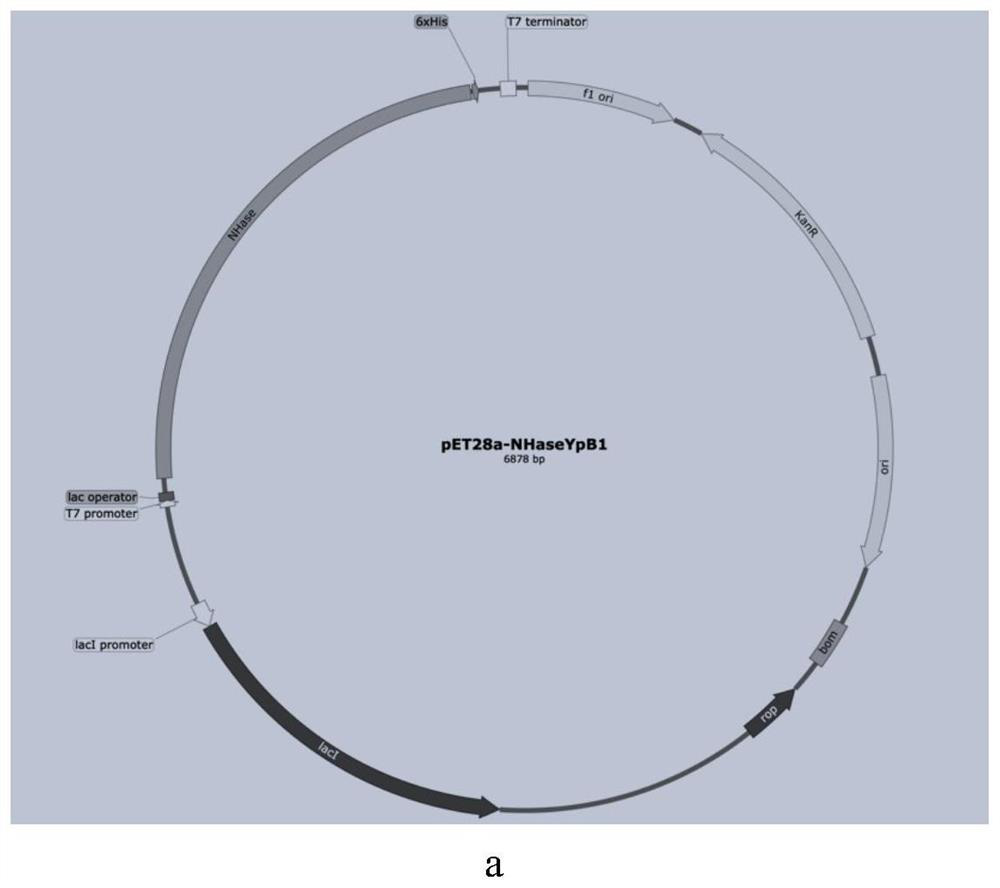

[0026]Embodiment 1, nitrile hydratase gene cloning and construction of engineering bacteria

[0027] 1. Engineering bacteria pET28a-NHaseYpB 1

[0028] (1) Wild-type nitrile hydratase

[0029] According to the nitrile hydratase (nitrolehydratase H-Nhase, GenBank: D67027.1) from Rhodococcus rose (R.rhodochrous J1) in NCBI, it contains β subunit (NHase-B), α subunit (NHase-A) and The three parts of the activator gene (NHase-G) were synthesized by Beijing Qingke Biotechnology Co., Ltd. after codon optimization according to the preference of Escherichia coli. The nucleotide sequence of the β subunit (NHase-B) is shown in SEQ ID 1-690 in NO.2, the alpha subunit (NHase-A) nucleotide sequence is shown in 691-1302 in SEQ ID NO.2, and the activator gene (NHase-G) nucleotide sequence is shown in Shown in positions 1303-1617 in SEQ ID NO.2.

[0030] (2) Fragment

[0031] β subunit fragment: take step (1) to synthesize the nitrile hydratase gene β subunit (NHase-B) fragment as a temp...

Embodiment 2

[0083] Embodiment 2, the induced expression of recombinant nitrile hydratase genetically engineered bacteria

[0084] The correct recombinant Escherichia coli engineering bacteria E.coil BL21(DE3)-pET28a-NHaseYpB sequenced in Example 1 1 , E.coil BL21(DE3)-pET28a-NHaseYpB 2 , E.coil BL21(DE3)-pET28a-NHaseYpB 3 , E.coil BL21(DE3)-pET28a-NHaseYpB 4 They were respectively inoculated in 10 mL liquid LB medium containing Kan (final concentration 50 μg / mL), and cultured at 37° C. for 10 h. The cultured seed solution was transferred to a new 100mL liquid LB medium containing Kan (final concentration 50μg / mL) at a volume concentration of 1% inoculum, cultivated under the same conditions until the OD600 of the bacterial solution was 0.6, and added a final concentration of 0.5 mM IPTG, then add 400 μL of 100 mM CoCl 2 Aqueous solution (final concentration 0.4mM), induced at 28°C for 12h; centrifuged at 9000rpm for 10min to collect bacteria. The cells were washed twice with PBS buff...

Embodiment 3

[0090] Embodiment 3, the impact of resin on enzyme-catalyzed reaction

[0091] Resin pretreatment: (1) Resins D201, D301, JKA915, BA765, D101, D311 (all purchased from Jiangsu Jinkai Resin Chemical Co., Ltd.) in Table 8 were mixed with 10% NaCl aqueous solution at a mass concentration about twice the volume of the resin in Soak in a beaker, stir the resin layer at a low speed of 20rpm for 1 hour, place the liquid level at a place 200-300mm above the resin layer and soak for 20 hours, then rinse with water until the effluent is colorless. (2) Then carry out backwashing to remove tiny impurities mixed in the resin, soak the resin layer with 4% HCl aqueous solution approximately equal to twice the volume of the resin for 1 hour, and put the liquid surface to 200-300mm above the resin layer to soak After 2-4 hours, rinse with clean water until the pH value of the effluent is 5-6. (3) After soaking the resin layer with a 2% NaOH aqueous solution with a mass concentration of about ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com