Method for preparing biochar bimetallic catalyst and lignin fluorescent carbon dots through straw grading and water treatment application of biochar bimetallic catalyst and lignin fluorescent carbon dots

A bimetallic catalyst and fluorescent carbon dot technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, oxidized water/sewage treatment, etc., can solve metal ion concentration monitoring, heavy metal ion pollution, Difficult to recycle and other problems, to achieve a wide range of PH application, easy to recycle, and solve the effects of poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

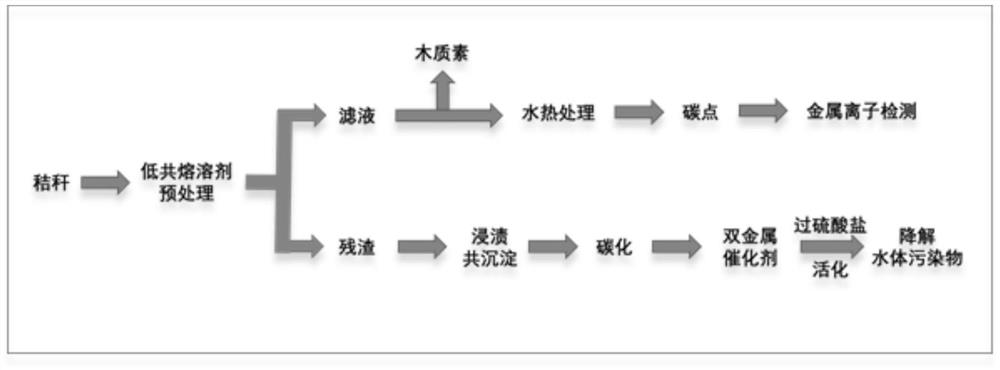

[0037] A method for preparing biochar bimetallic catalysts and lignin fluorescent carbon dots by graded straw, specifically comprising the following steps:

[0038] (1) Mix choline chloride and lactic acid at a mass ratio of 1:15, and stir magnetically at a constant temperature in a water bath at 80°C for 1 hour to generate a uniform and transparent deep eutectic solvent with a certain viscosity;

[0039] (2) cleaning, drying and pulverizing the straw to obtain straw powder;

[0040](3) Mix the straw powder in step (2) and the deep eutectic solvent prepared in step (1) at a solid-to-liquid ratio of 1:20, stir in a water bath at 90°C for 12 hours, filter after the reaction, and deionized water cleaning the residue, and freeze-drying the residue of straw to obtain a mixture of residue of straw and lignin-deep eutectic solvent;

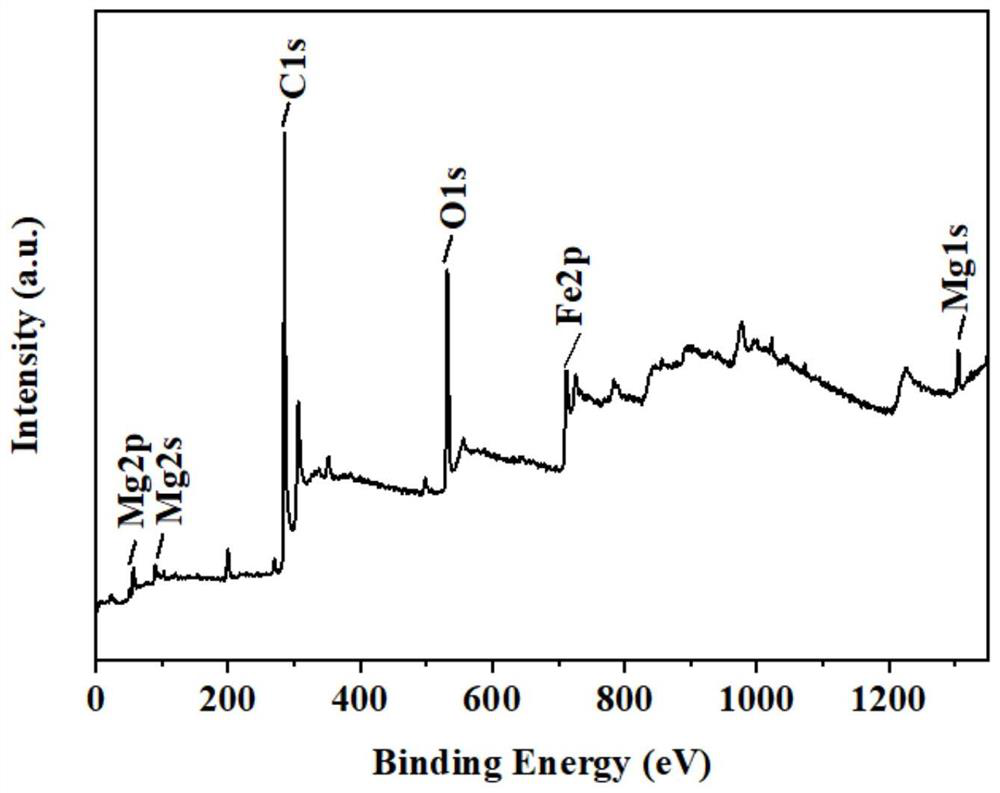

[0041] (4) FeCl 3 ·6H 2 O and MgCl 2 ·6H 2 O mixed in water to dissolve, control FeCl 3 ·6H 2 O concentration is 0.4M, MgCl 2 ·6H 2 O concentra...

Embodiment 2

[0057] The difference between this embodiment and embodiment 1 is: FeCl in 100ml precursor solution 3 ·6H 2 O is 0.2M, MgCl 2 ·6H 2 O is 0.4M.

[0058] The catalyst obtained in this embodiment is under the same experimental conditions as in Example 1, and the removal rate of Arbiduoer reaches 92.23% in 60 minutes.

Embodiment 3

[0060] The difference between this embodiment and Example 1 is: in step (1), FeCl in 100ml precursor solution 3 ·6H 2 O is 0.4M, MgCl 2 ·6H 2 O is 0.4M.

[0061] The catalyst obtained in this embodiment is under the same experimental conditions as in Example 1, and the removal rate of Arbiduoer reaches 95.44% in 60 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com