Strain and method for producing hydroxytyrosol

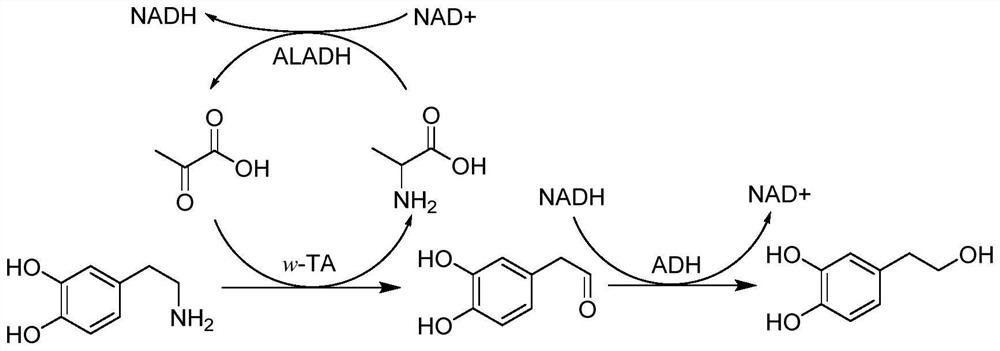

A technology of hydroxytyrosol and alcohol dehydrogenase, which is applied in the field of microbial genetic engineering, can solve problems such as low cost, differences between batches, and obstacles to industrialization, and achieve the goals of reducing by-products, avoiding losses, and reducing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Cloning of Example 1 Gene

[0062] (1) Primer design

[0063] Design primers for PCR amplification.

[0064] Table 1 Primer sequence list

[0065]

[0066]

[0067] Note: The underline is the restriction endonuclease site

[0068] (2) PCR amplification

[0069] According to the instruction manual of the Genomic DNA Purification Kit of Takara Company, the genomic DNA of the wild strain in logarithmic growth phase was extracted, and the genome extracted from each corresponding strain was used as a template for PCR amplification. Amplification system: Prime STARHS DNA Polymerase (2.55U / μL) 0.5μL, 10×PrimeSTAR Buffer 5μL, dNTP Mixture (2.5mM each) 4μL, Template DNA 1μL, Up primer (20μM) 1μL, Down primer (20μM) 1μL , ddH 2 O make up to 50 μL. The amplification program was: 94°C, 30sec; 55°C, 30sec; 72°C, 2min, a total of 30 cycles: 72°C, 5min. PCR products were sent for sequencing.

[0070] cvta, bata, and pdta were cloned from Chromobacterium violaceum, Brucel...

Embodiment 2

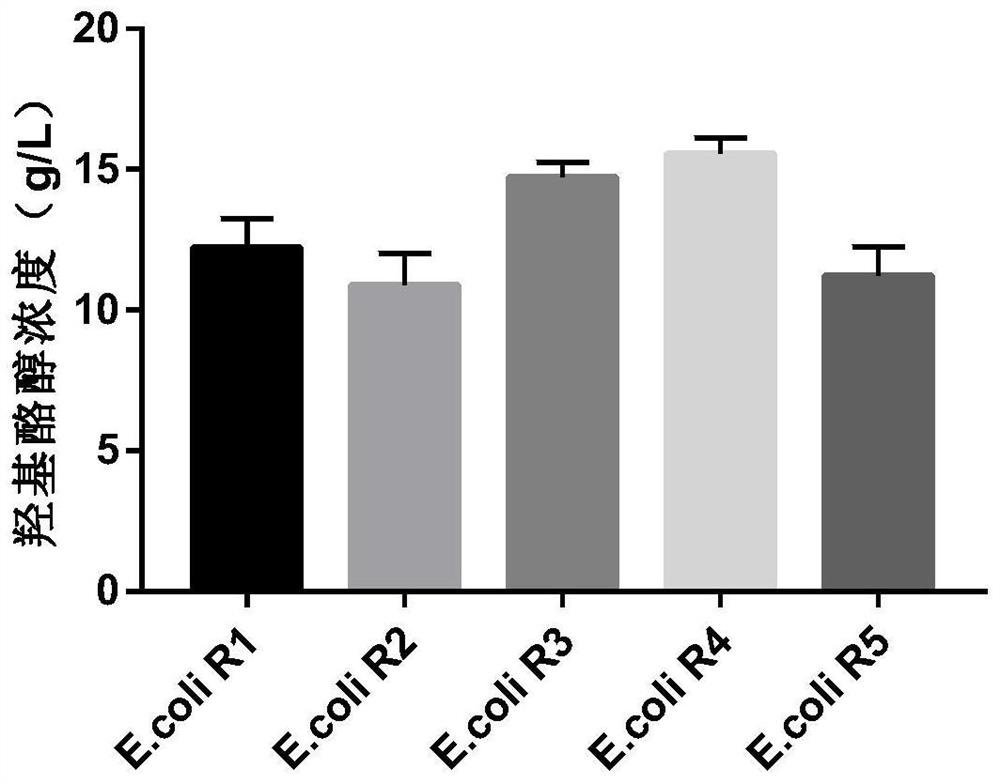

[0077] Example 2 Expression of ω-transaminase from different sources

[0078] The recombinant Escherichia coli expressing different sources of ω-transaminase constructed in Example 1 was cultivated to obtain seed liquid, and the seed liquid was transferred to LB fermentation medium (peptone 10g / L, yeast powder 5g / L in an amount of 2% by volume respectively). L, NaCl 10g / L), when the cell OD 600 After reaching 0.6-0.8, IPTG with a final concentration of 0.4 mM was added to induce expression and culture at 25°C for 15 h. After induction of expression, cells were collected by centrifugation at 4°C, 8000 rpm, and 20 minutes. After ultrasonication, the supernatant was centrifuged at 4°C, 8000 rpm for 20 minutes to obtain the crude enzyme solution, and the activity of the crude enzyme solution was measured. The results are shown in Table 2. The ω-transaminase derived from Chromobacterium violaceum was more effective for deamination of dopamine.

[0079] Table 2 ω-transaminase act...

Embodiment 3

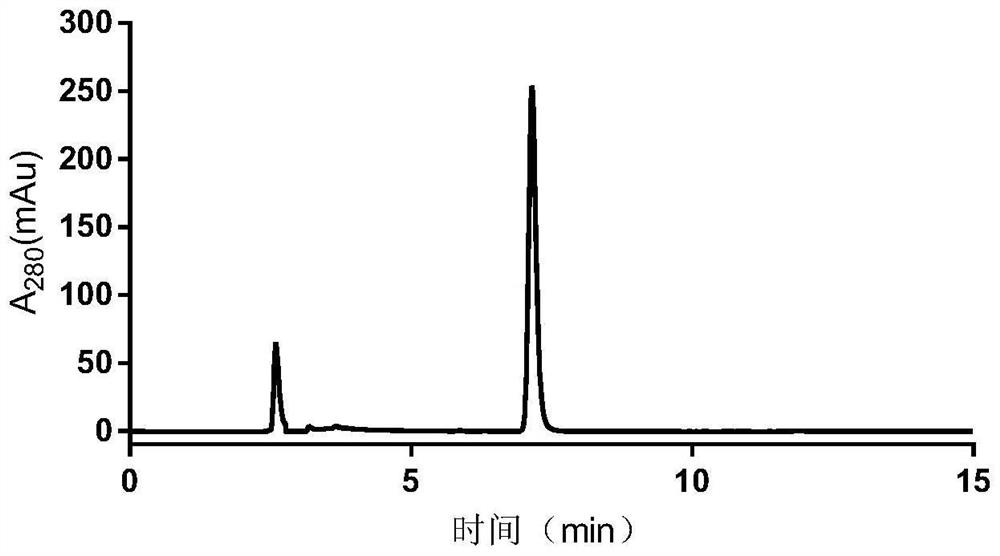

[0082] Example 3 Expression of alanine dehydrogenases from different sources

[0083] Recombinant Escherichia coli expressing bsaladh (GenBank: QJR47777.1), haaladh (GenBank: RDU72374.1), and mtaladh (GenBank: WP_003899477.1) derived from Bacillus subtilis, Helicobacteraurati, and Mycobacterium tuberculosis were constructed in the same manner as in Example 1. , and according to the same method in Example 2, the recombinant E. coli was cultured to induce the expression of the enzyme. Determination of crude enzyme activity. The results are shown in Tables 3 and 4, and the alanine dehydrogenase derived from Bacillus subtilis was more effective in the conversion reaction of hydroxytyrosol.

[0084] Table 3 Oxidative activity of alanine dehydrogenase

[0085] Recombinant bacteria Activity (U / mL) E.coli BL21 / pET-28a-bsaladh 28.1 E.coli BL21 / pET-28a-haaladh 25.8 E.coli BL21 / pET-28a-mtaladh 14.0

[0086] Table 4 Reductase activity of alanine dehydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com