Metal monatomic doped biomass charcoal adsorption material as well as preparation method and application thereof

A technology of biomass charcoal and adsorption material, applied in the field of environmental engineering, can solve the problems of inability to effectively remove drinking water degrading organic matter, increase adsorption performance and adsorption stability, etc., and achieve easy large-scale production, increase adsorption performance and adsorption stability. Effective and efficient removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] Based on the above-mentioned metal single-atom-doped biomass carbon adsorption material, the present invention also discloses a preparation method of a metal single-atom-doped biomass carbon adsorption material, characterized in that the steps are as follows:

[0035] Step 1: First put the dry biomass into a 4mol / L sodium hydroxide solution, the mass ratio of the dry biomass and sodium hydroxide is 2:1-1:2, carry out the pretreatment process, and stir at room temperature for 12-36h. (Among them, too much sodium hydroxide dosage will cause excessive hydrolysis of cellulose components in the biomass material, which in turn affects the single-atom loading; too little sodium hydroxide dosage will cause lignin in the biomass structure to be removed. Insufficient hydrolysis of the components affects the structural rearrangement of carbon in the subsequent calcination process.) After that, the reaction solution is put into an oven, and the temperature is adjusted to 60-80° C. f...

Embodiment 1

[0039] Preparation of metal single-atom doped biomass carbon adsorption materials:

[0040] Preferably coconut shell is used as biomass material, first put 10g dry coconut shell into 4mol / L sodium hydroxide solution, the mass ratio of dry coconut shell and sodium hydroxide is 1:1, carry out the pretreatment process, stir at room temperature for 36h, After that, the reaction solution was put into an oven, and the temperature was adjusted to 60° C. to react for 24 hours. Take out the coconut shell after pretreatment, and clean the residual alkaline solution on the surface. It was then put into a 0.03 mol / L ferric chloride aqueous solution, the molar amount of ferric chloride added was 0.02 times the molar amount of sodium hydroxide added, and the mixture was stirred at room temperature for 24 hours. After that, the reaction solution was placed in a 60° C. oven until the reaction solution was completely dried, and then placed in a corundum porcelain boat. Take 1g of sodium hydr...

Embodiment 2

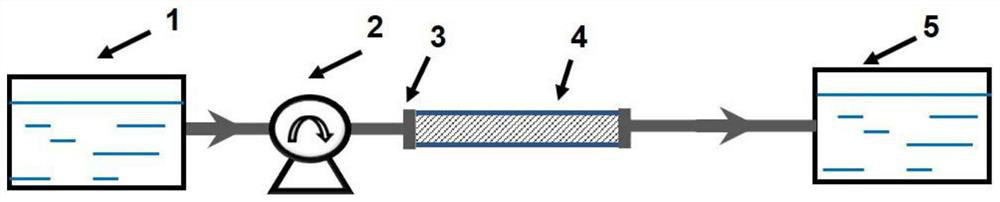

[0043] The adsorption performance ratio of different metal single-atom doped biomass carbon materials: using perfluorooctanoic acid (PFOA), ciprofloxacin (CIP) and tris(2-chloroethyl) phosphate (TCEP) as target pollutants, respectively, prepared with tap water The 1 μg / L aqueous solution was used as the influent, and the BC-Fe 1 , BC-Cu 1 , BC-Ni 1 , BC-Sc 1 , BC-Mn 1 , BC-V 1 , BC-Ti 1 , BC-Sm 1 , BC-Er 1 , BC-Ce 1 , BC-Eu 1 and BC-Nd 1 The material is ground, sieved with a 40-mesh sieve, filled with a filter column after sieving, and placed in a dynamic adsorption test system, the test temperature is 25 ° C, and the continuous operation is 48 hours. After filtration through the filter membrane, put it in a plastic sample bottle at 60°C to evaporate the water, elute the sample bottle with 2 mL of ultrapure water, rinse it three times, and then use solid-phase extraction to extract the organic matter in it for testing.

[0044] The PFOA in the samples was determined...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com