Bismuth ion doped fluorescent powder and preparation method and application thereof

A fluorescent powder and luminous intensity technology, applied in the direction of fluorescence/phosphorescence, chemical instruments and methods, luminescent materials, etc., can solve the problems of restricting large-scale applications, low light transmittance of glass, etc., and achieve excellent thermal stability and chemical properties The effect of stability and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

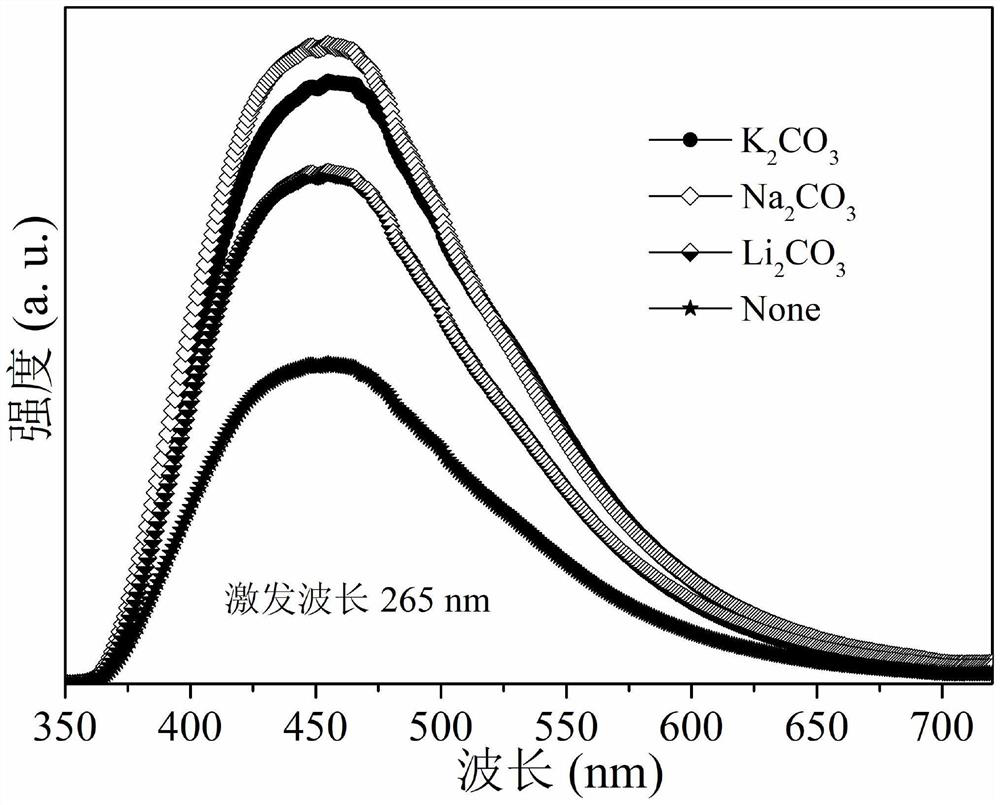

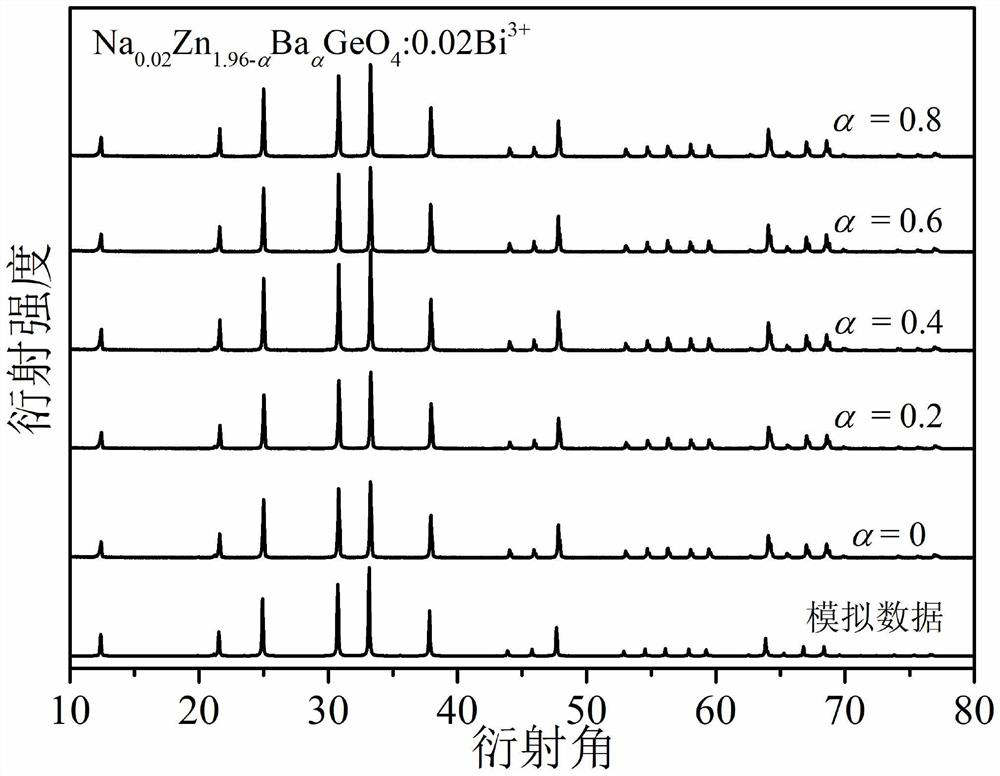

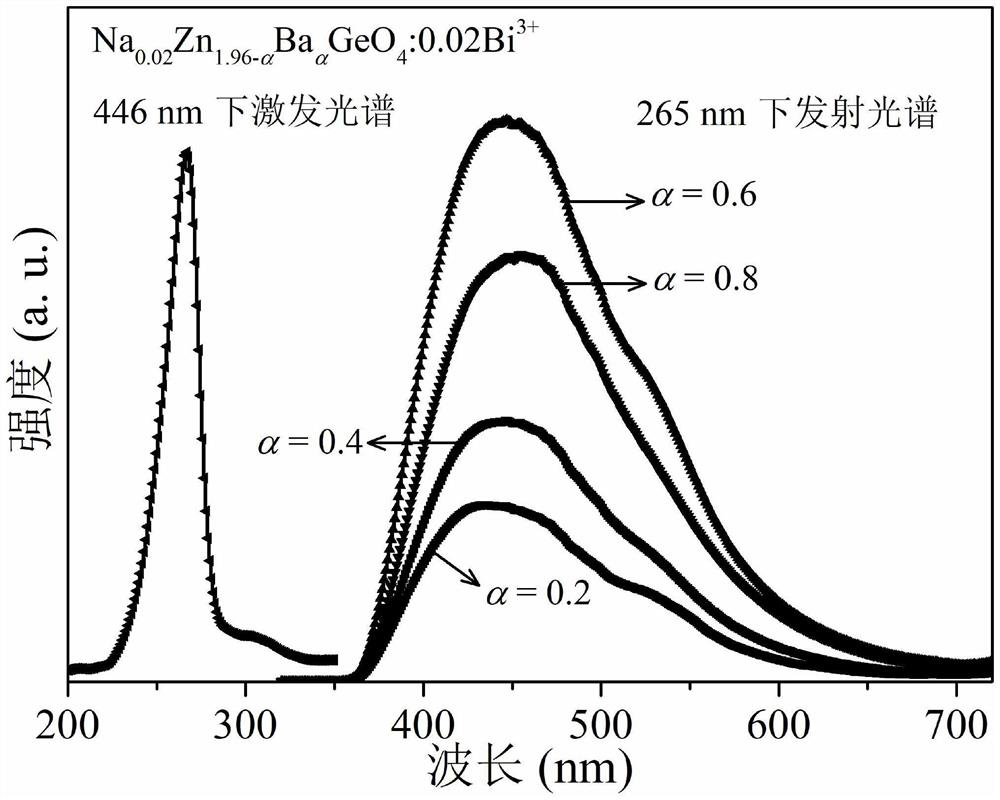

[0042] The present embodiment is prepared according to the following method and the chemical formula is Na 0.02 Zn 1.96-α Ba α GeO 4 :0.02Bi 3+ (α=0, 0.2, 0.4, 0.6, 0.8) phosphor.

[0043] Na 0.02 Zn 1.96-α Ba α GeO 4 :0.02Bi 3+ (α=0,0.2,0.4,0.6,0.8) Phosphor preparation process: using barium carbonate (99.9%), zinc oxide (99.9%), germanium oxide (99.9%), bismuth oxide (99.99%) as raw materials, carbonate Sodium (99.9%) was used as a charge compensation agent, and the raw materials were weighed according to the general chemical formula:

[0044] barium carbonate Zinc oxide germanium oxide Bismuth oxide Sodium carbonate α=0 0.0000g 0.3049g 0.2000g 0.0089g 0.0020g α=0.2 0.0754g 0.2738g 0.2000g 0.0089g 0.0020g α=0.4 0.1509g 0.2426g 0.2000g 0.0089g 0.0020g α=0.6 0.2263g 0.2115g 0.2000g 0.0089g 0.0020g α=0.8 0.3017g 0.1804g 0.2000g 0.0089g 0.0020g

[0045] The raw materials were uniformly mixed according...

Embodiment 2

[0051] The present embodiment is prepared according to the following method and the chemical formula is Na 0.02 Zn 1.36 Ba 0.6 Ge 1-β-γ Si β Sn γ O 4 :0.02Bi 3+ (β=0~0.6; γ=0~0.4) phosphor.

[0052] Na 0.02 Zn 1.36 Ba 0.6 Ge 1-β-γ Si β Sn γ O 4 :0.02Bi 3+ (β=0~0.6; γ=0~0.4) Phosphor preparation process: using barium carbonate (99.9%), zinc oxide (99.9%), germanium oxide (99.9%), silicon oxide (99.9%), tin oxide ( 99.9%), bismuth oxide (99.99%) as raw material, sodium carbonate (99.9%) as charge compensation agent, take by weighing the raw materials according to the general chemical formula:

[0053]

[0054] The raw materials were uniformly mixed according to the ratio of ball:material:absolute ethanol=4:2:1 to obtain a mixture precursor, which was put into a corundum crucible, and pre-sintered at a low temperature and normal pressure of 600 ° C for 5 hours. Sintering at 1400°C for 6h in a hydrogen-nitrogen mixture or a hydrogen-argon mixture, cooling to roo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| internal quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com