Hollow fiber heterogeneous membrane as well as preparation method and application thereof

A hollow fiber technology, applied in the field of hollow fiber heteromembrane and its preparation and application, can solve the problems affecting oxygenation membrane performance, many modification steps, platelet adhesion, etc., and achieves remarkable surface modification effect and high gas permeability. The effect of improving performance and blood compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A block copolymer modified heterogeneous PMP hollow fiber oxygenation membrane is prepared, and the preparation steps are as follows:

[0029] Step 1. Take 200g of PMP raw material, 800g of dioctyl phthalate and 20g of polyethylene-block-poly(ethylene glycol) respectively and add them to the feed liquid kettle, and stir the casting liquid at 240°C for 6h until a homogeneous phase is formed. solution, let stand for defoaming for 12h.

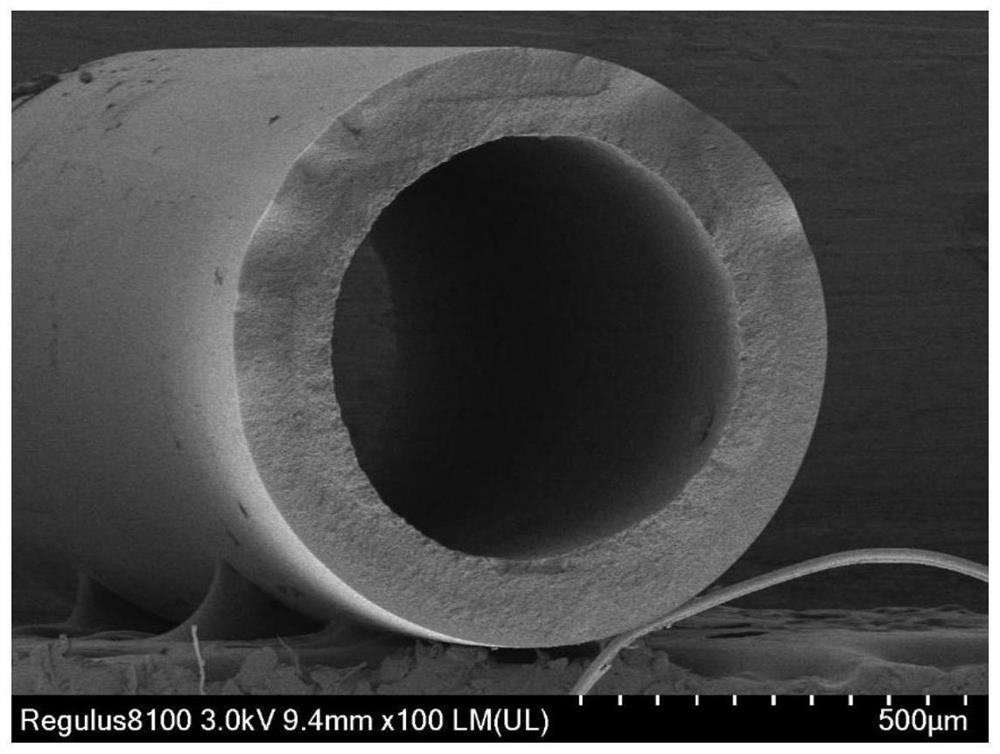

[0030]Step 2. The homogeneous film casting liquid obtained in step 1 is extruded through a high-temperature spinneret at a rate of 15ml / min, and the flow rate of the core liquid used to form the hollow structure is 40ml / min, and then it is solidified and formed by cooling water and completed. The surface of the block copolymer is enriched, and then the winding is completed by the winding wheel, and the winding speed is 1.15 m / s.

[0031] Step 3. Soak the membrane obtained in Step 2 in absolute ethanol for 48h to make it fully extracted. ...

Embodiment 2

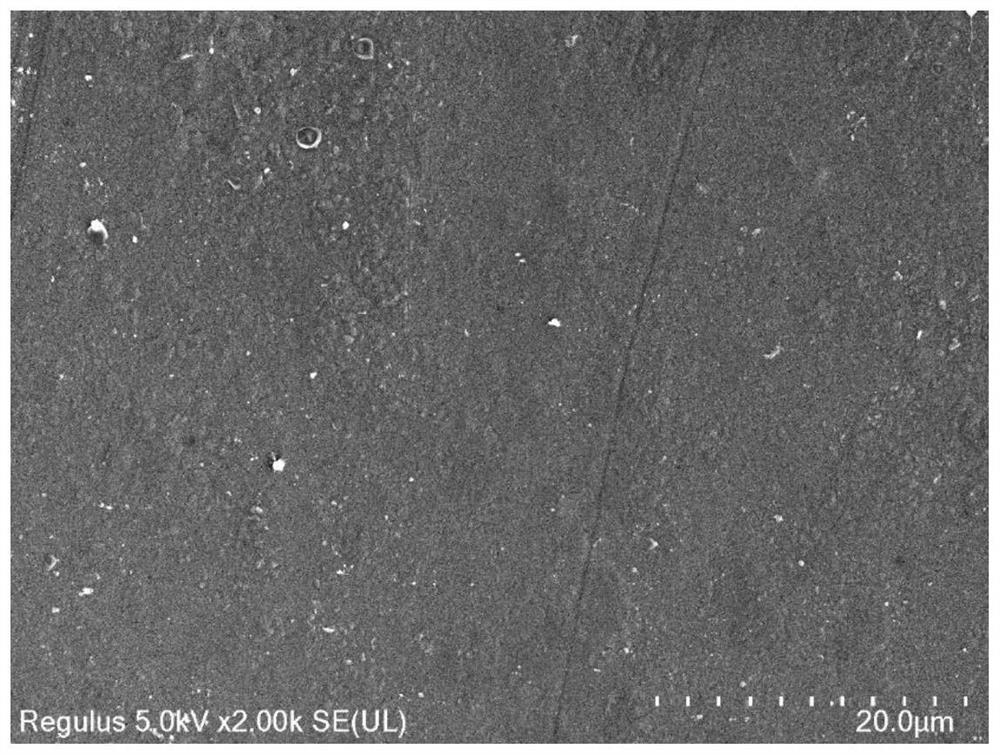

[0034] To prepare a block copolymer-modified heterogeneous PMP hollow fiber oxygenation membrane, the preparation steps of Example 2 are basically the same as those of Example 1, except that in Step 1, the amphiphilic block copolymer was changed from 20 g The polyethylene-block-poly(ethylene glycol) was changed to 15g of Pluronic F127, the quality of PMP raw material was changed from 200g to 300g, and the quality of dioctyl phthalate was changed from 800g to 700g. In step 2, the extrusion speed of the feed liquid in the process conditions of extrusion molding and winding and winding was changed from 15ml / min to 23ml / min, and the flow rate of the core liquid was changed from 40ml / min to 50ml / min; finally obtained The membrane is denoted as membrane 2.

[0035] Measured according to the same test method of Example 1: the water contact angle of the membrane 2 is 83°; the hemolysis rate is 5.33%; the oxygen permeation rate is 1.79ml / (min·cm 2 bar).

Embodiment 3

[0037] A block copolymer modified heterogeneous PMP hollow fiber oxygenation membrane was prepared,

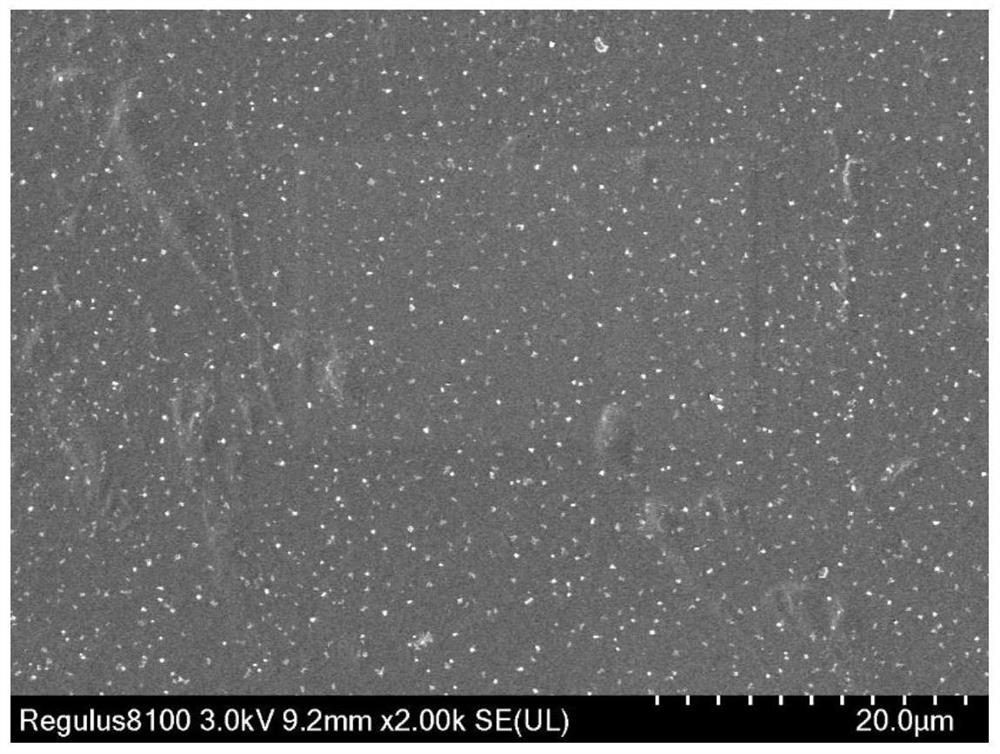

[0038] The preparation steps of Example 3 are basically the same as those of Example 1, except that in Step 1, the amphiphilic block copolymer was changed from 20g polyethylene-block-poly(ethylene glycol) to 45g ethylene-ethylene. Alcohol copolymer (EVOH). In step 2, the extrusion speed of the feed liquid in the process conditions of extrusion molding and winding and winding was changed from 15ml / min to 7.5ml / min, the flow rate of the core liquid was changed from 40ml / min to 20ml / min, and the The rotation speed of the winding wheel (ie, the speed of wire take-up) was changed from 1.15m / s to 0.64m / s, and the film finally obtained was recorded as film 3.

[0039] Measured according to the same test method of Example 1: the water contact angle of the membrane 3 is 66°; the hemolysis rate is 3.49%; the oxygen permeation rate is 1.88ml / (min cm 2 bar).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water contact angle | aaaaa | aaaaa |

| Water contact angle | aaaaa | aaaaa |

| Water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com