Aqueous coating containing three layer nuclear shell structure rubber particle latex and its preparation method

A technology of latex particles and core-shell structure, applied in coatings, latex paints, etc., can solve the problems of increased system viscosity, high toxicity of raw materials, easy curing, etc., and achieves simple coating operation process, good storage stability performance, storage good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Preparation of three-layer core-shell emulsion:

[0025] A. Preparation of core layer polymer:

[0026] Add 34 kg of deionized water, 0.15 kg of disodium alkyl dibenzene sulfonate, 0.30 kg of reactive emulsifier allyl polyethylene into a 100-liter enamel reaction kettle with condensate, stirring, thermometer, and dropping device Oxygen sulfonate (SEN-10), 9.1 kg of styrene, 2.8 kg of butyl acrylate, 0.1 kg of divinylbenzene, stirred and emulsified, passed nitrogen for 20 minutes, raised the temperature to 40°C to initiate polymerization, added 0.012 kg of potassium persulfate and 0.012 kg of sodium bisulfite aqueous solution (the amount of water is 400 grams), after initiating the reaction for 1 hour, the reaction temperature of the system is gradually maintained at 60±2°C.

[0027] B: Preparation of sub-outer polymer:

[0028] Mix 2.5 kg of methyl methacrylate, 5.0 kg of butyl acrylate, 1.5 kg of glycidyl methacrylate, dropwise with 0.009 g of potassium persulfat...

Embodiment 2-12

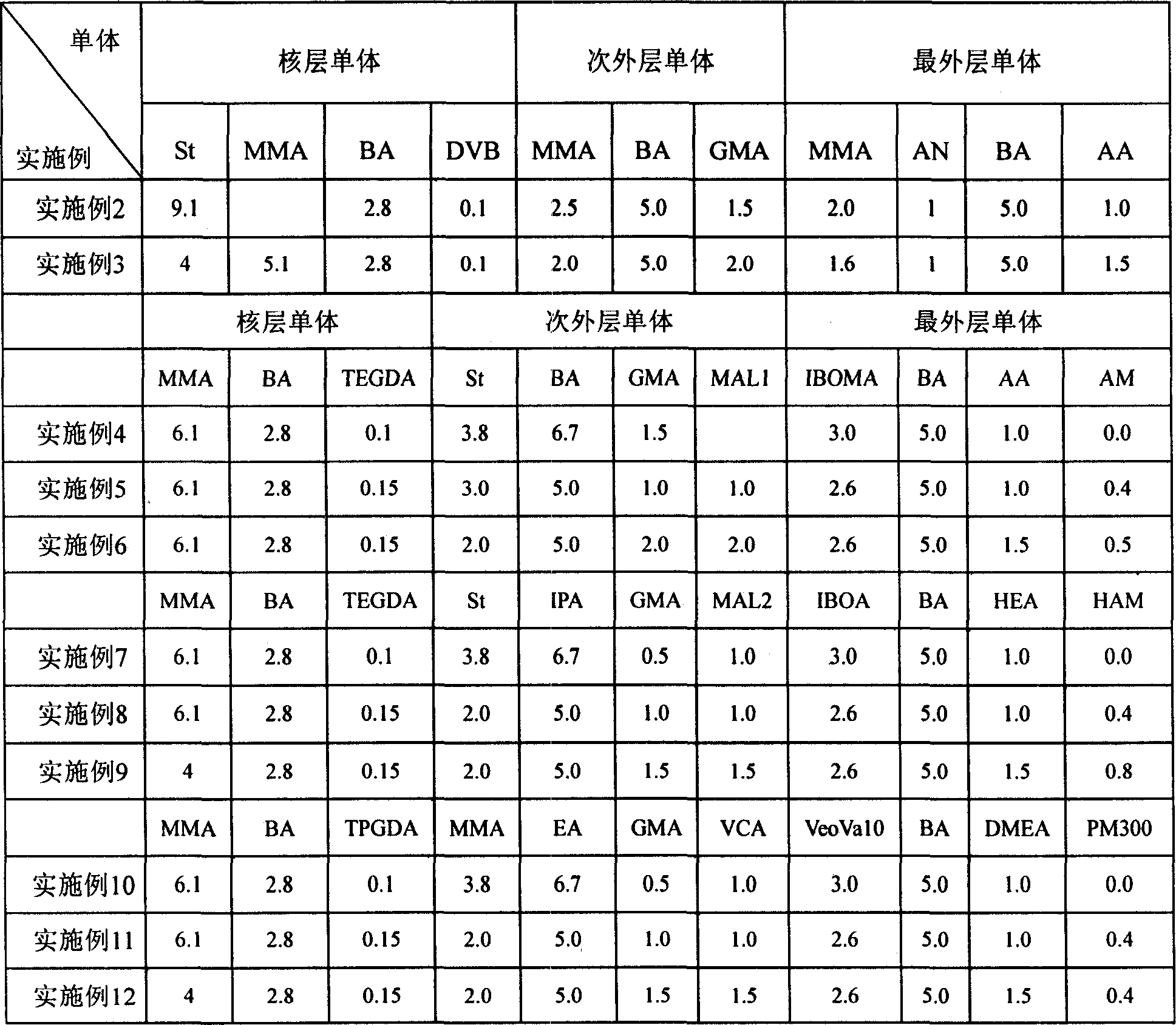

[0040] Embodiment 2-12: The monomers used in the synthesis of latex particles and their dosage are shown in Table 1, and other preparation conditions are the same as in Embodiment 1.

[0041] Table 1: The monomers and consumptions used in the synthetic latex particles of embodiment 2-12

[0042] Unit: kg

[0043]

[0044] In the table, St is styrene, MMA is methyl methacrylate, BA is butyl acrylate, DVB is divinylbenzene, GMA is glycidyl methacrylate, AN is acrylonitrile, AA is acrylic acid; TEGDA triethylenic Glycol dimethacrylate, MAL1 maleic anhydride, IBOMA isobornyl methacrylate, AM is acrylamide; IPA isoamyl acrylate, IBOA is isobornyl acrylate, HEA is hydroxyethyl acrylate, MAL2 is butene Diacid anhydride, HAM is methylol acrylamide, TPGDA tripropylene glycol dimethacrylate, EA ethyl acrylate, VCA vinyl chloroacetate, VeoVa-10 vinyl tertiary carbonate, DMEA N methacrylate, N dimethyl Amino ethyl ester.

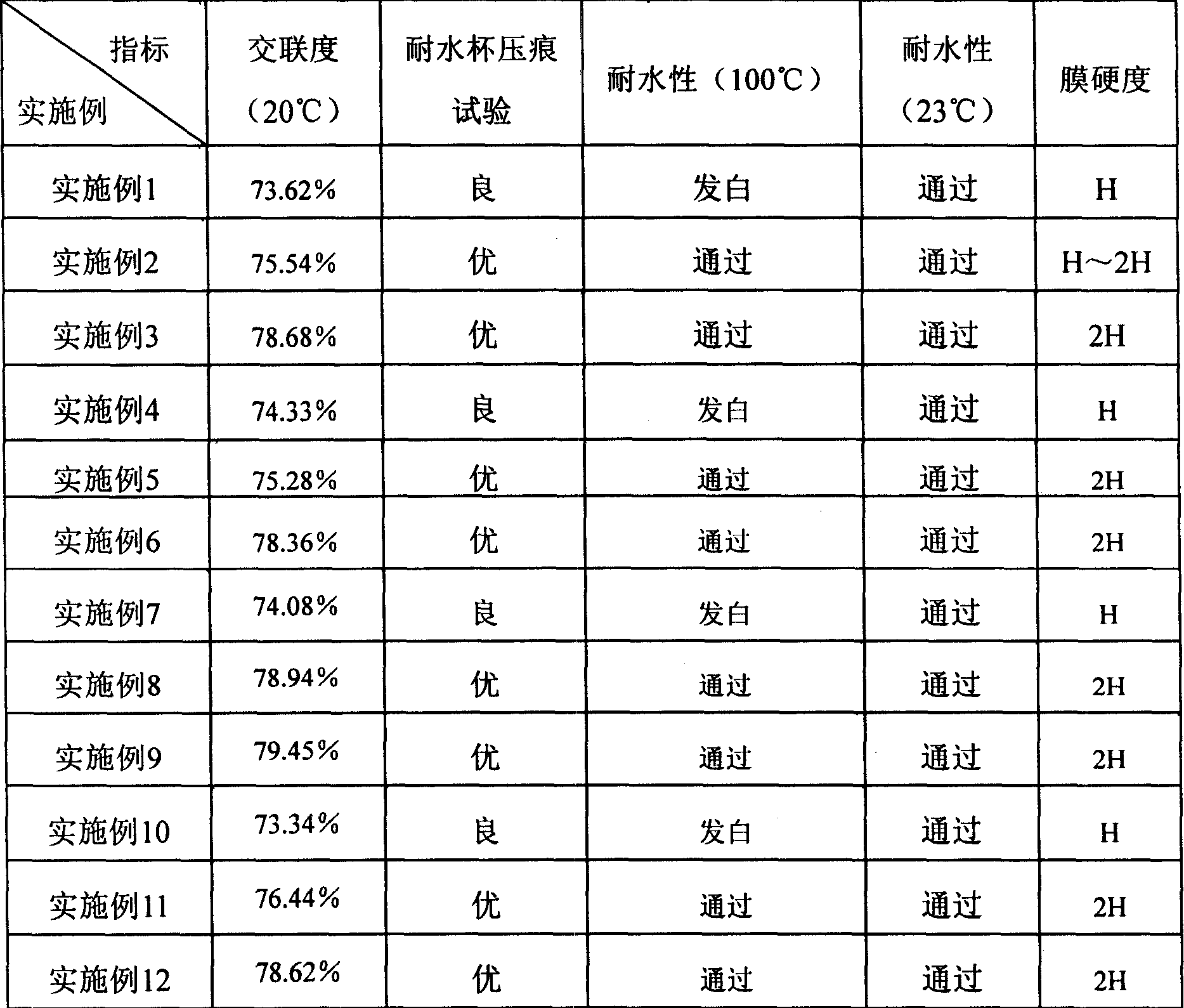

[0045] Table 2: Te...

Embodiment 13-18

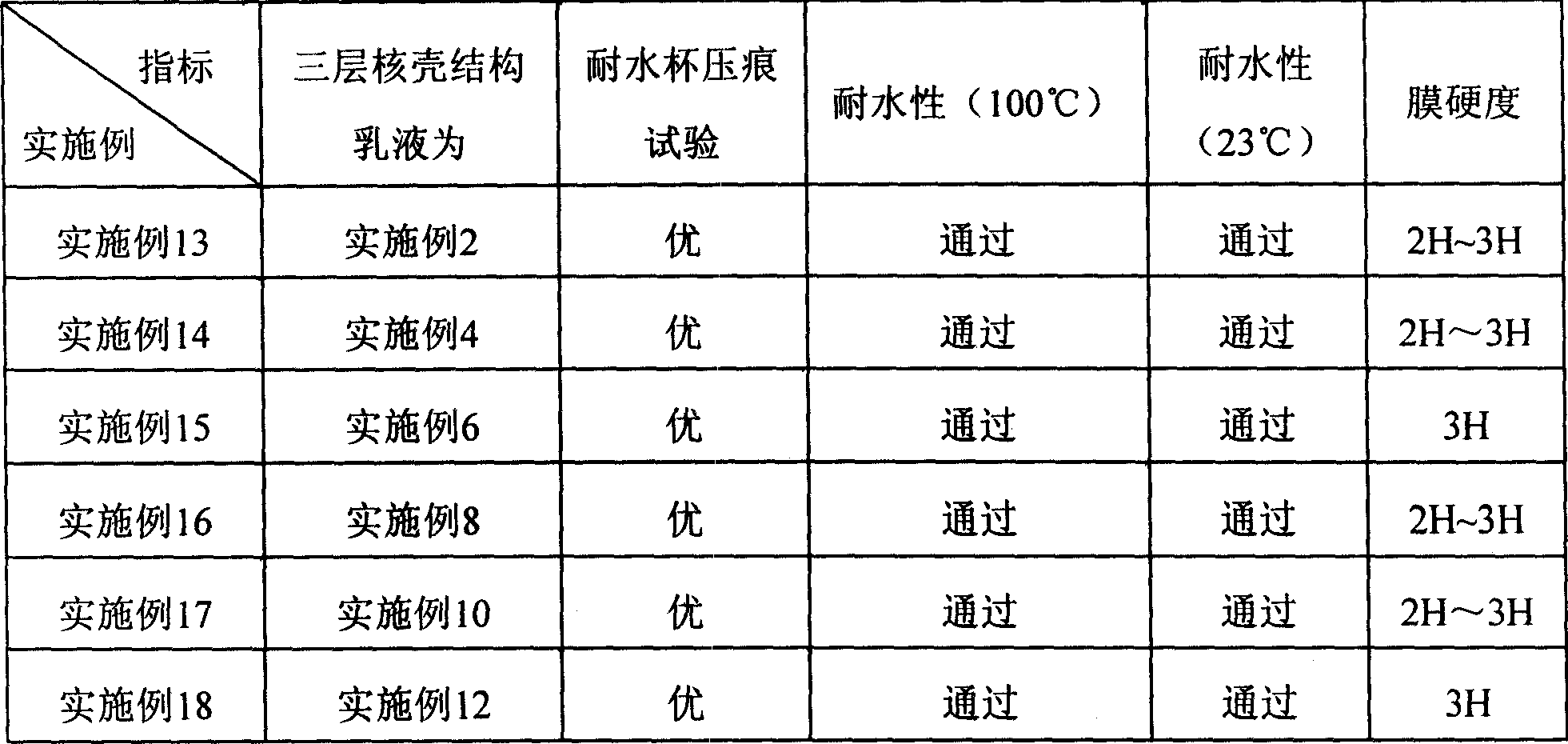

[0047] Embodiment 13-18: the configuration of color paint type coating

[0048] Add 100 parts of deionized water, 5 parts of dispersant DP-270, 1.5 parts of defoamer 681F into the 200-liter dispersion tank of the high-speed disperser, stir at 1200 rpm for 10 minutes, and slowly add commercially available rutile titanium dioxide in sequence 50 parts, 10 parts of kaolin, 5 parts of talcum powder, continue to stir and disperse for 20 minutes, grind twice with a sand mill, and the fineness reaches below 30 microns to form a pigment slurry for use.

[0049] Add 100 parts of the three-layer core-shell structure emulsion of step (1) in Example 2, 4, 6, 8, 10 or 12 of the present invention into the stirring tank, start stirring, and stir at 100-300 rpm , Add dropwise 0.2 parts of pH regulator AMP95, 5 parts of film-forming aid 795, 2 parts of film-forming aid (propylene glycol), 0.5 part of wetting agent, and 0.2 part of defoamer 681F.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com