Vascularized fat depot based on partition and construction method thereof

A technology of adipose tissue and construction method, applied in the field of bioengineering, can solve problems such as no breakthrough progress, difficulty in stabilization, hard breast tissue of synthetic polymer materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] Example 1 Extraction and Induced Culture of Adipose Stem Cells

[0075] The patient's autologous fat was obtained by liposuction, the adipose tissue was washed with phosphate buffer, and then 0.75g / LI type collagenase was added, shaken and digested at 37°C for 60min, and the digestion was terminated with fetal bovine serum. Centrifuge at 1200r / min for 10min, remove the supernatant and suspended residual tissue, resuspend the cells, add 2 times the volume of red blood cell lysate (NH 4 Cl 154mmol / L+KHCO 3 10mmol / L+EDTA 0.1mmol / L) let stand for 10min, centrifuge and discard the supernatant. Wash with an appropriate amount of PBS for 3 times, and filter through a 200-mesh sieve to obtain adipose tissue stem cells.

[0076] Inoculate the obtained adipose tissue stem cells on 25cm 2 Add 5 mL of high-glucose DMEM medium containing 0.10 volume fraction of fetal bovine serum to the culture bottle, mix well, and place in 37°C, 0.05 volume fraction of CO 2 Cultured in a satur...

Embodiment 2

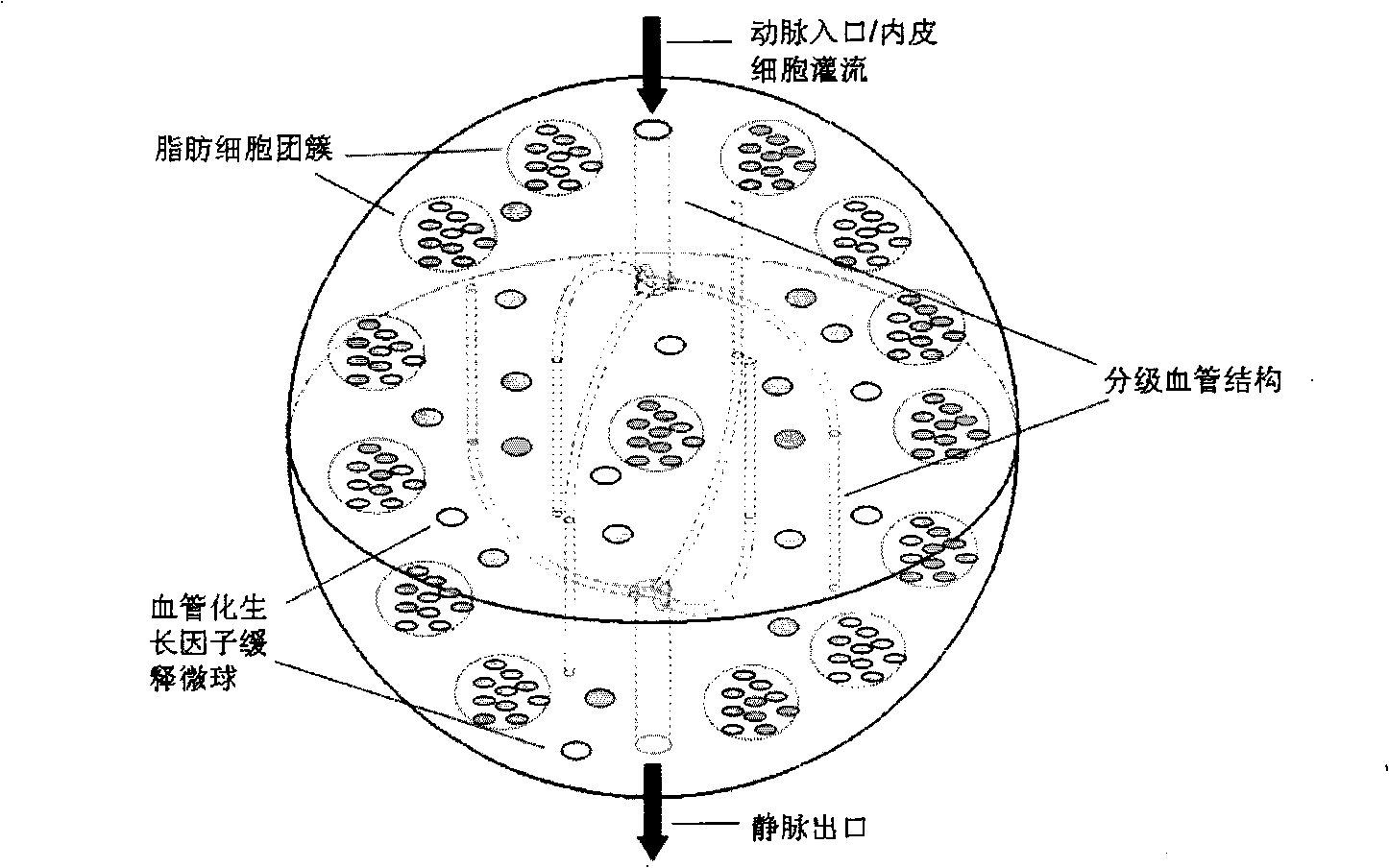

[0091] Using core-melting technology (patent publication number: 1654028) to prepare two sets of internally connected secondary vascular stents, such as image 3 shown. The first level simulates the biological structure of small blood vessels with an inner diameter of 1000 μm, and the second level structure simulates microvessels with an inner diameter of 300 μm. They are cultivated and trained in a pulsating bioreactor for 2 hours a day for one week, and the circulating fluid is 10 6 pcs / ml smooth muscle cell suspension (the solvent is the corresponding cell culture medium), so that the smooth muscle cells evenly attach to the channel of the vascular stent to form multi-layered smooth muscle cells.

[0092] The fat stem cell microcapsules and growth factor sustained-release microspheres prepared in Example 1 were uniformly mixed with gelatin at room temperature at a volume ratio of 10:1:5, cast into a hemisphere with a diameter of 2 cm, and then cooled to gel; Two sets of gr...

Embodiment 3

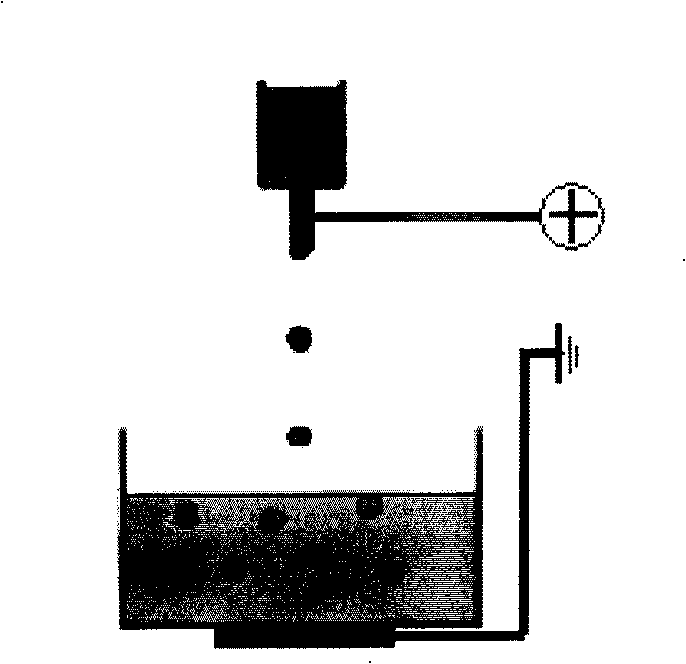

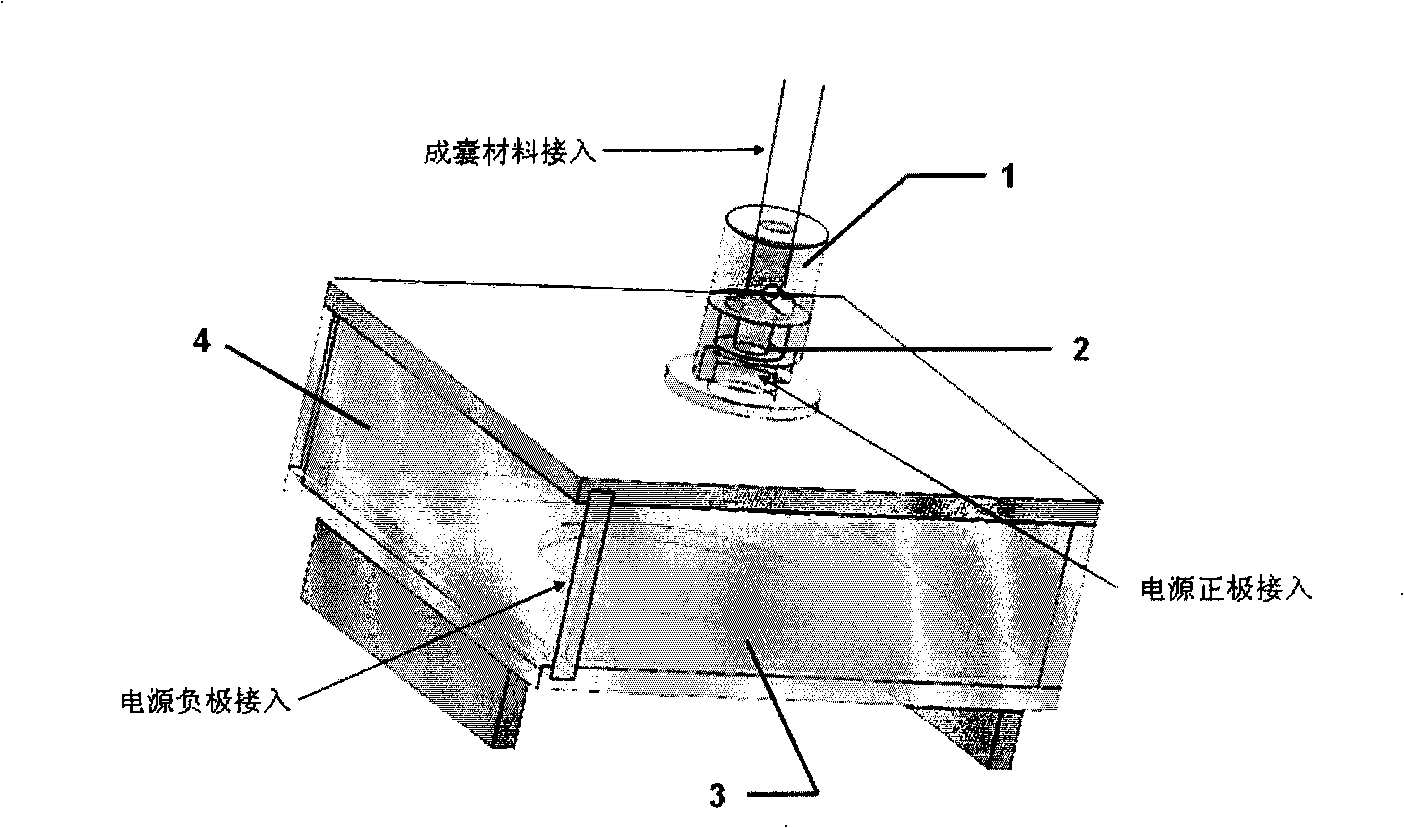

[0094] Adipose stem cells cultured routinely were taken using sodium alginate / gelatin system as encapsulation material, and a non-contact high-voltage electrostatic generator (see figure 2 ) to make solid cell microcapsules:

[0095] 1. The sodium alginate solution and the gelatin solution (solvent PBS buffer solution) were mixed to obtain solutions with final concentrations of 1.8% (w / w) and 3% (w / w), respectively.

[0096] 2. Adipose-derived stem cells were treated with 10 6 The density per ml is evenly mixed with the encapsulating solution and then filled into a disposable needle tube with a volume of 10 ml.

[0097] 3. Connect the non-contact high-voltage electrostatic microcapsule generator. The high-voltage electrostatic generating device of this equipment can use SA167-Y (Tianjin) high-voltage electric field generator with an output voltage of 10kV; Syringe pump, using a 5mL syringe, the distance between the needle tip and the copper sheet is 10mm, the advancing spee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com