Single dye type bright acidic copper plating additive and preparation method and application thereof

An acidic copper plating and additive technology, applied in the field of copper plating additives, can solve the problems of insufficient fineness of the high and middle areas of the coating, the influence of the polarization of the plating solution, and increase the production cost, etc., and achieve excellent deep plating ability and good filling and leveling performance of the coating , easy to manage the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

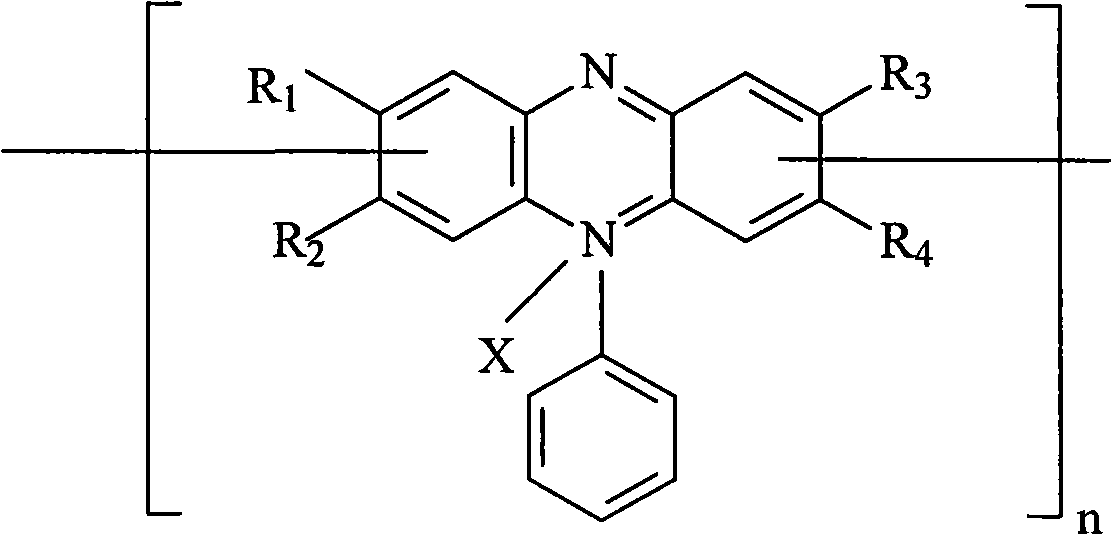

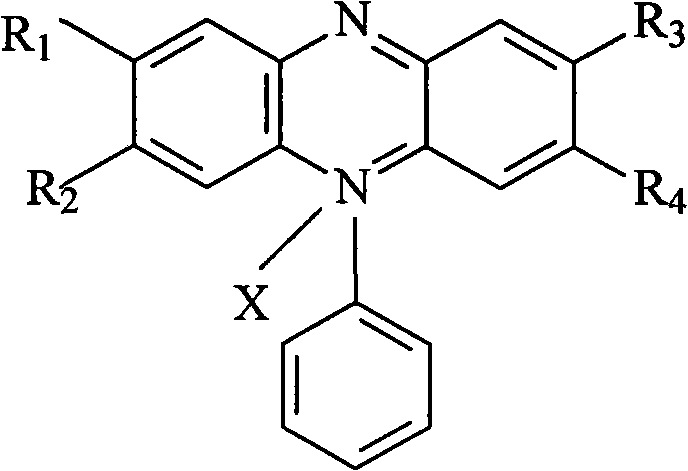

[0046] Synthesis of self-made polymerized phenazine dyes: add 20ml of concentrated hydrochloric acid or concentrated sulfuric acid to a four-necked flask, and 1g of 3-amino-7-(N,N dimethylamino)-2-methyl-5-phenyl-phenazine Add the monomer and 300mg cupric chloride or nickel chloride powder into the flask, stir to suspend it in the acid, heat to 60-65°C, slowly add saturated sodium nitrite aqueous solution dropwise, continue stirring for 1- Cool to room temperature after 1.5h. 15 ml of 50% (wt%) sodium hydroxide solution was added dropwise at room temperature, and the reaction solution was cooled with an ice-water bath. The resulting reaction solution was filtered to obtain a dark purple solid, which was dried.

[0047] Through high-performance liquid chromatography and mass spectrometry, it is found that the yield of the desired polymerization product is 80-85% (wt%), and the rest is unreacted monomers.

Embodiment 2

[0049] 1) Preparation of additives (1L)

[0050] Azophenazine polymer hydrochloride (Guangzhou Chaorun Chemical) 3g

[0051] Gentian violet 2g

[0052] Methylene blue 1g

[0053] Polypropylene Glycol 1000 5g

[0054] Macrogol 2000 5g

[0055] Sodium polydithiobutane sulfonate 2.5g;

[0056] Preparation method: Add about 300ml of water into a large beaker, add 2g of sulfuric acid and stir evenly, add polypropylene glycol, polyethylene glycol and sodium polydithiobisbutane sulfonate, stir for at least 1 hour to completely dissolve, and then add azo Phenazine polymer hydrochloride (super-moisturizing), gentian violet and methylene blue, stir for more than 3 hours until completely dissolved, and dilute to 1L.

[0057] 2) Preparation and use of bright acidic copper plating solution (1L)

[0058] CuSO 4 ·6H 2 O 210g

[0059] h 2 SO 4 33ml

[0060] Cl - 100mg

[0061] Additive 2.5ml

[0062] Preparation meth...

Embodiment 3

[0066] 1) Preparation of additives (1L)

[0067] Azophenazine Polymer Sulfate (Keyu Chemical) 5g

[0068] Gentian violet 1.5g

[0069] Lowe's Violet 0.8g

[0070] Polypropylene glycol 600 7g

[0071] Macrogol 1000 8g

[0072] Sodium polydithiodipropane sulfonate 3g;

[0073] Preparation method is with embodiment 2.

[0074] 2) bright acidic copper plating solution preparation (1L) and use are the same as embodiment 2

[0075] Plating piece (Hull cell test piece) as an example: take 250ml of the prepared plating solution and put it into the Hull cell, keep room temperature, under the condition of strong air bubbling, use phosphor copper plate as the anode, conduct electroplating, current 2A, time 10min . The whole plated sheet is bright, without fogging, and there is no pitting and pitting on the surface.

[0076] Pilot test: Prepare 25L of plating solution, add it to the pilot test plating tank, and under strong bubbling, carry out rack plating on the degreasing and ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com