Double-channel MOS-HEMT (Metal Oxide Semiconductor-High Electron Mobility Transistor) device and manufacturing method

A dual-channel, device technology, used in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of obvious self-heating effect, serious gate leakage current, current collapse effect, etc., to reduce the self-heating effect. , The effect of reducing gate leakage current and high breakdown voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

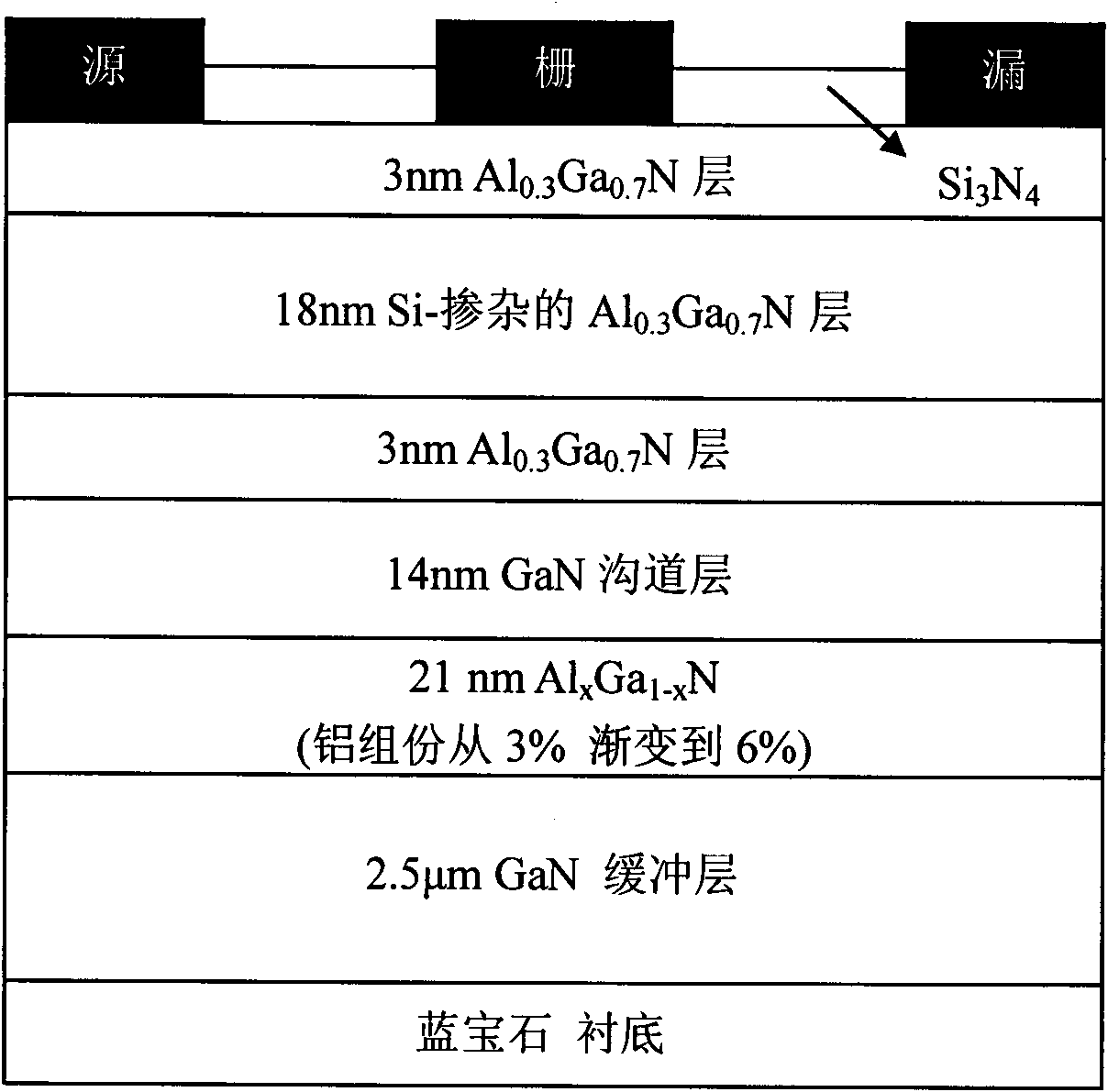

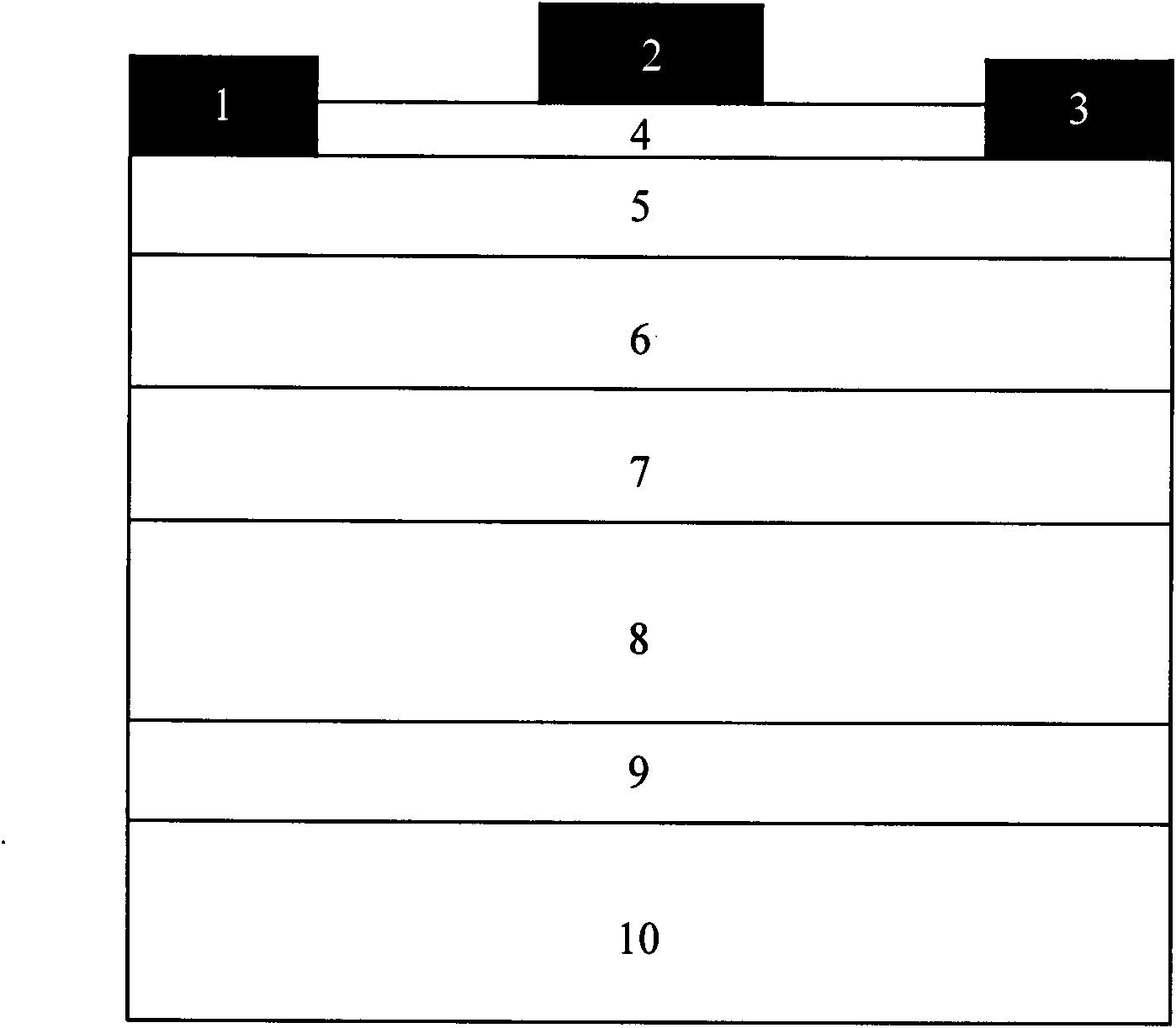

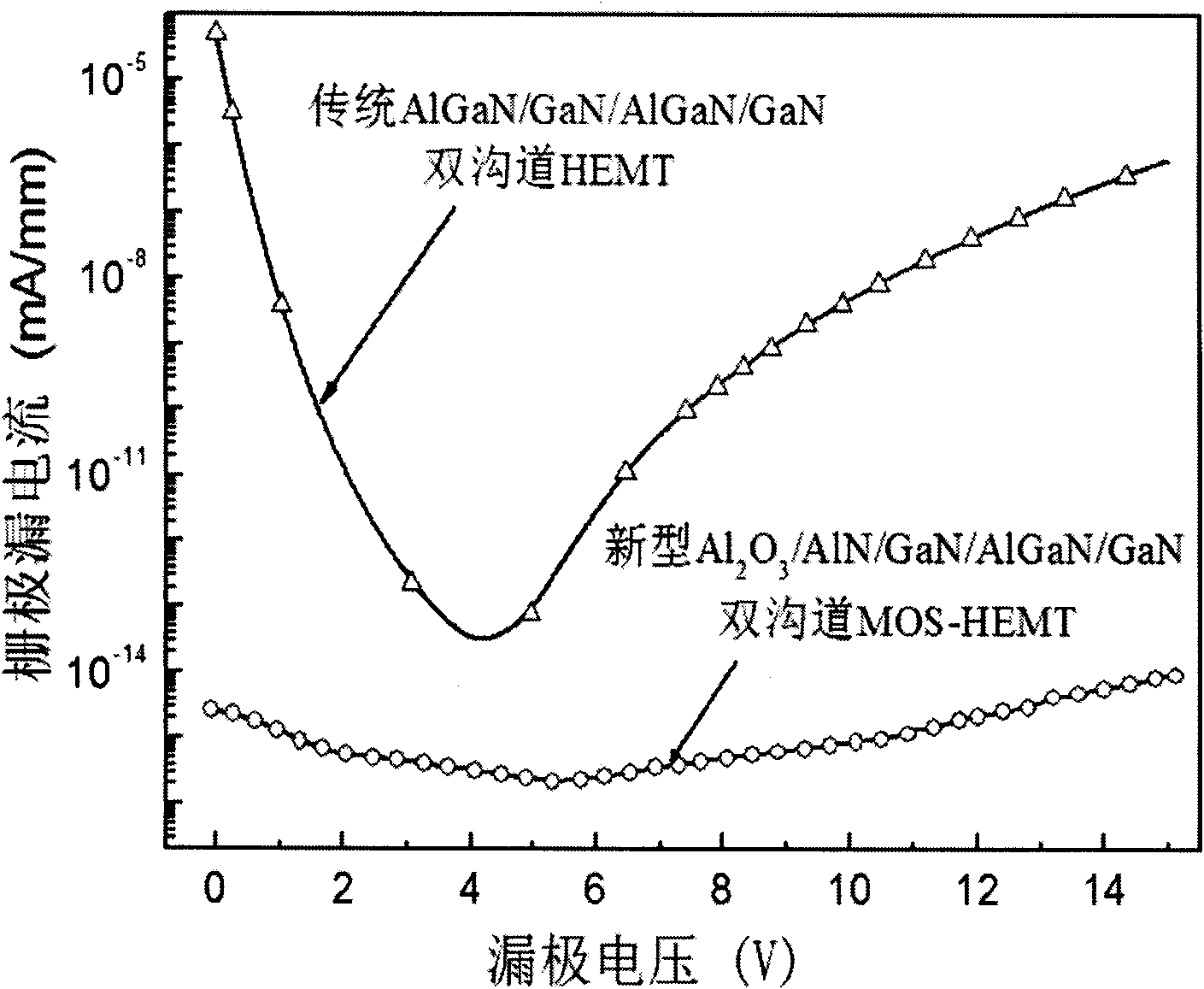

[0051] The present invention simulates the traditional AlGaN / GaN / AlGaN / GaN dual-channel HEMT and the Al 2 o 3 The electrical characteristics of the / AlN / GaN / AlGaN / GaN dual-channel MOS-HEMT thus prove the superiority of the new device of the present invention in suppressing current collapse and self-heating effects compared with traditional devices. image 3 To compare the relationship between the gate leakage current and the drain voltage of the device of the present invention and the traditional device, it can be seen from the figure that the gate leakage current of the device of the present invention is lower than that of the traditional device by more than 4 orders of magnitude. Figure 4 For the comparison of the output characteristics of the device of the present invention and the traditional device, it can be seen from the figure that the drain current density of the device of the present invention has obviously increased, which shows that the polarizability of AlN is be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com