Zinc isomorphism-substituted nano molecular sieve catalyst and preparation method and application thereof

A catalyst, molecular sieve technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of large crystal grains, long crystallization time, unsatisfactory and other problems, and achieve high aromatics selectivity and easy separation. , cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

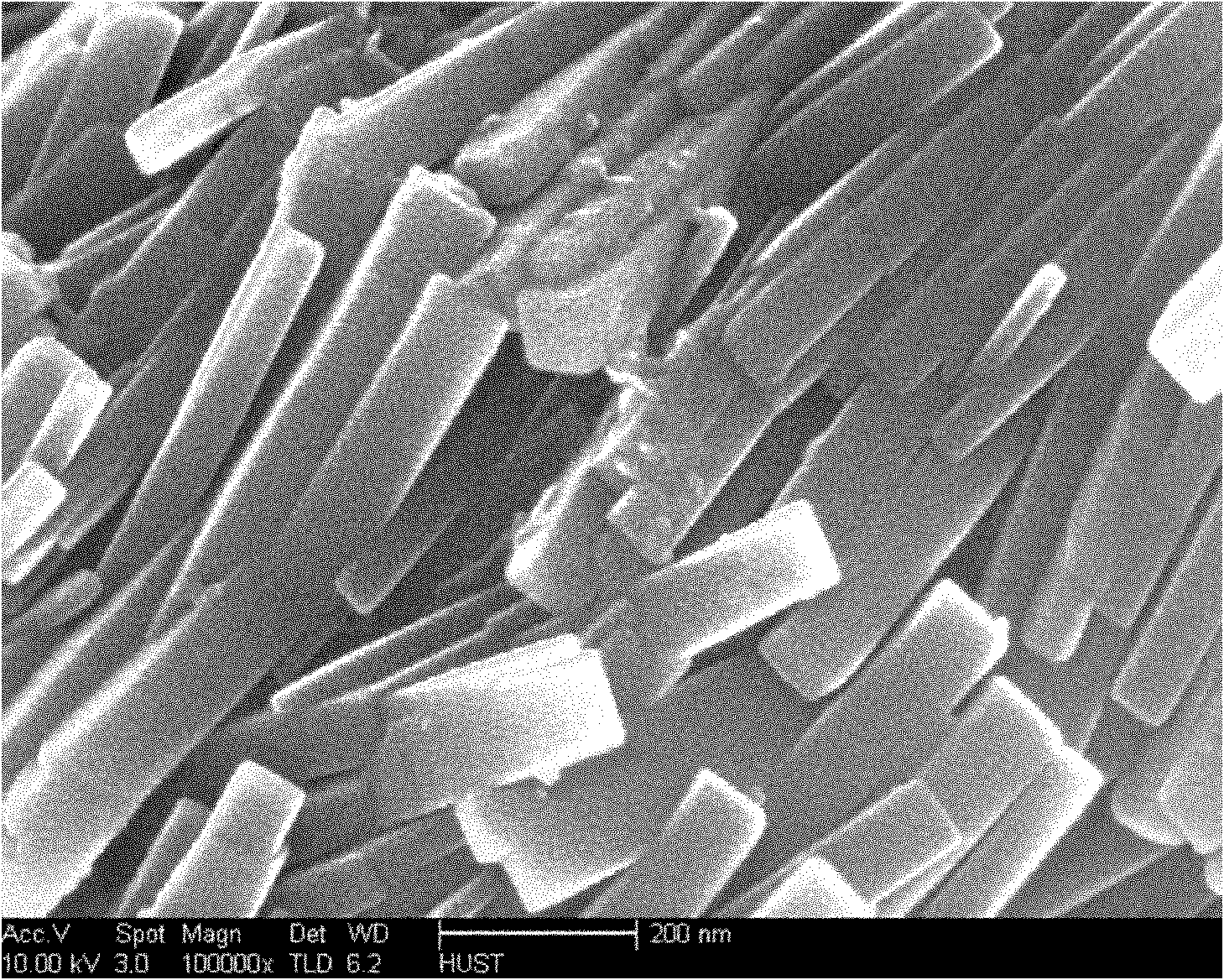

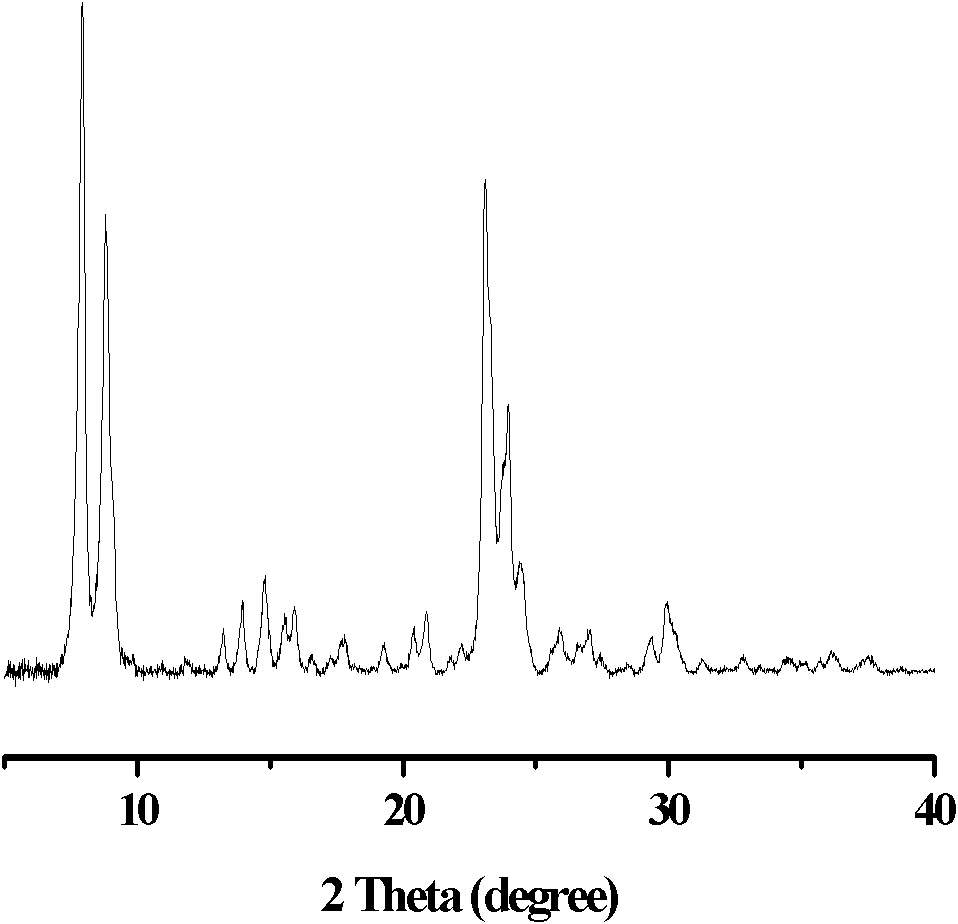

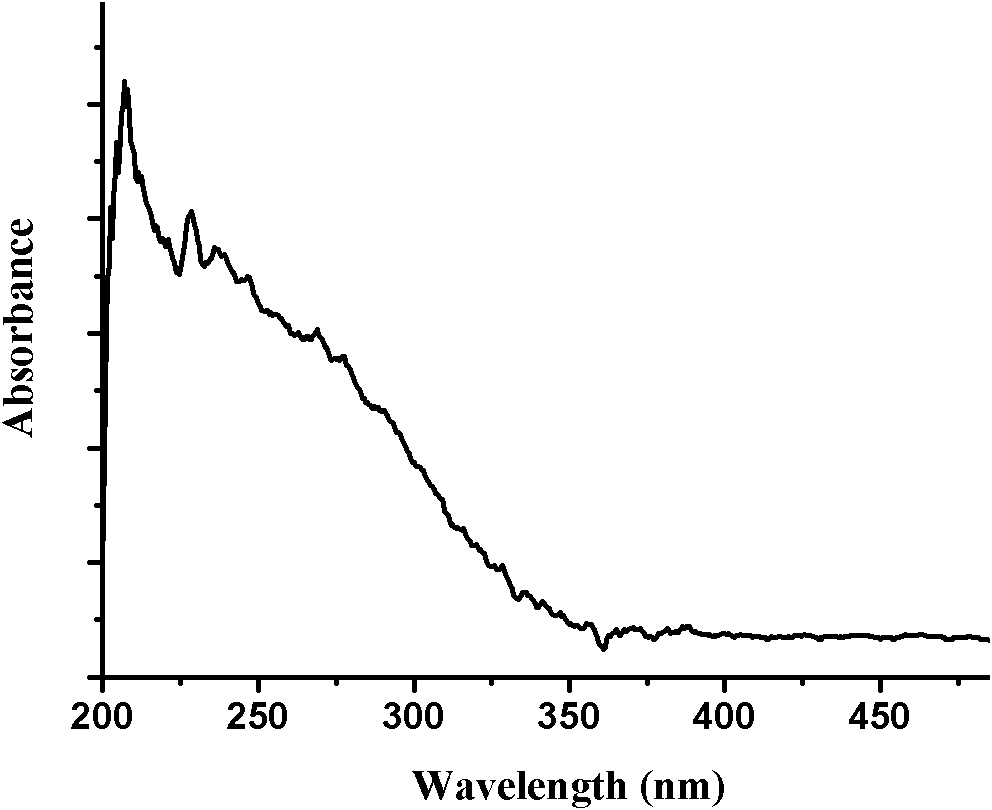

[0043] Embodiment 1: One of preparation scheme of catalyst of the present invention

[0044] The molar ratio of crystallization raw material is SiO 2 : 0.02Al 2 o 3 : 0.14NaOH: 0.20TPAOH: 0.01ZnO: 30H 2 o

[0045] (1) Preparation of silica-alumina gel

[0046] Weigh 2.8g of sodium hydroxide and dissolve it in 40ml of water, slowly add the prepared sodium hydroxide aqueous solution dropwise to 100g of silica sol with a mass fraction of 30%, stir at room temperature for 10min; then slowly add dropwise 0.33mol / L of partial aluminum 60ml sodium nitrate solution, stirred at room temperature for 20min; then slowly added 81.2g aqueous solution of tetrapropylammonium hydroxide with a mass fraction of 20%, stirred at room temperature for 30min to obtain silica-alumina gel.

[0047] (2) Preparation of zinc ammonia solution

[0048] Weigh 1.48g of zinc nitrate hexahydrate and dissolve it in 20ml of water, and coordinate the prepared zinc salt solution with 1.40g of ammonia water wi...

Embodiment 2

[0053] Embodiment 2: The preparation scheme two of catalyst of the present invention

[0054] The molar ratio of crystallization raw material is SiO 2 : 0.005Al 2 o 3 :0.08NaOH:0.05TPAOH:0.04ZnO:40H 2 o

[0055] (1) Preparation of silica-alumina gel

[0056] Weigh 1.6g of sodium hydroxide and dissolve it in 40ml of water, slowly add the prepared aqueous sodium hydroxide solution dropwise to 274g of water glass with a mass fraction of 25%, stir at room temperature for 10min; then slowly add dropwise 0.04mol / L of aluminum sulfate 60 ml of the solution was stirred at room temperature for 20 min; then 20.3 g of tetrapropylammonium hydroxide with a mass fraction of 20% was slowly added, and stirred at room temperature for 30 min to obtain silica-alumina gel.

[0057] (2) Preparation of zinc amine solution

[0058] Weigh 5.74g of zinc sulfate heptahydrate and dissolve it in 20ml of water, coordinate the prepared zinc salt solution with 6.20g of 40% methylamine aqueous solution...

Embodiment 3

[0060] Embodiment 3: the third preparation scheme of the catalyst of the present invention

[0061] The molar ratio of crystallization raw material is SiO 2 : 0.025Al 2 o 3 :0.3KOH:0.5TPABr:0.005ZnO:60H 2 o

[0062] (1) Preparation of silica-alumina gel

[0063] Weigh 8.4g of potassium hydroxide and dissolve it in 120ml of water, slowly add the prepared aqueous potassium hydroxide solution dropwise into 104g of tetraethyl orthosilicate, stir at room temperature for 10min; then slowly add dropwise 180ml of 0.14mol / L aluminum nitrate solution, Stir at room temperature for 20 min; then slowly add 200 ml of tetrapropylammonium bromide solution with a concentration of 1.25 mol / L, and stir at room temperature for 30 min to obtain silica-alumina gel.

[0064] (2) Preparation of zinc amine solution

[0065] 0.34g of anhydrous zinc chloride was weighed and dissolved in 20ml of water, and the prepared zinc salt solution was coordinated with 0.45g of ethylamine to obtain a zinc amine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com