Process for treating chemical nickel-plating discarded liquid

A technology of electroless nickel plating and treatment process, applied in the direction of oxidized water/sewage treatment, improvement of process efficiency, chemical instruments and methods, etc., can solve the problems of high treatment cost, small saturated adsorption capacity, complicated process operation, etc., and achieve reduction The effect of nickel content, reduction of phosphorus discharge, and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

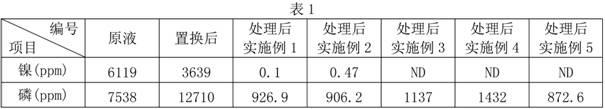

Embodiment 1

[0042] A preferred solution of the electroless nickel plating waste liquid treatment process of the present invention comprises the following steps:

[0043] 1) Collect the waste solution of electroless nickel plating to the PP tank, and put it into the iron plate to replace and recover nickel;

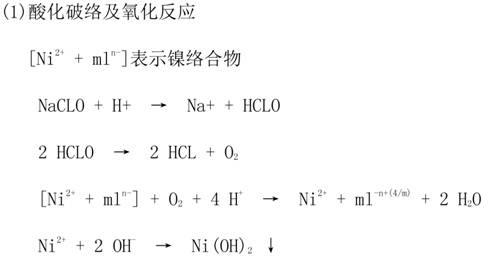

[0044] 2) Import the waste liquid obtained in the previous step into the acidification tank for acidification, and add sulfuric acid to adjust the pH to 1.5 to 2.0;

[0045] 3) Add 10% sodium hypochlorite solution to the pool, the volume ratio of sodium hypochlorite solution to waste liquid is 5:1;

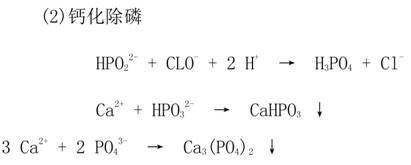

[0046] 4) Import the waste liquid obtained in the previous step into the calcification tank, add milk of lime, and adjust to pH=7;

[0047] 5) Pump the waste liquid and sediment obtained in the previous step to the filter press for filtration;

[0048] 6) Discharge the filter press effluent obtained in the previous step to the comprehensive pool of the wastewater station for subsequent ...

Embodiment 2

[0050] A preferred solution of the electroless nickel plating waste liquid treatment process of the present invention comprises the following steps:

[0051] 1) Collect the waste solution of electroless nickel plating to the PP tank, and put it into the iron plate to replace and recover nickel;

[0052] 2) Import the waste liquid obtained in the previous step into the acidification tank for acidification, and add hydrochloric acid to adjust the pH to 1.5 to 2.0;

[0053] 3) Add 37% hydrogen peroxide solution into the pool, the volume ratio of hydrogen peroxide solution to waste liquid is 1.5:1;

[0054] 4) Import the waste liquid obtained in the previous step into the calcification tank, add milk of lime, and adjust to pH=7;

[0055] 5) Pump the waste liquid and sediment obtained in the previous step to the filter press for filtration;

[0056] 6) Discharge the filter press effluent obtained in the previous step to the comprehensive pool of the wastewater station for subsequ...

Embodiment 3

[0058] A preferred solution of the electroless nickel plating waste liquid treatment process of the present invention comprises the following steps:

[0059]1) Collect the waste solution of electroless nickel plating to the PP tank, and put it into the iron plate to replace and recover nickel;

[0060] 2) import the waste liquid obtained in the previous step into the acidification tank for acidification, and add hydrochloric acid to adjust the pH to be 3;

[0061] 3) Add 10% sodium hypochlorite solution to the pool, the volume ratio of sodium hypochlorite solution to waste liquid is 8:1;

[0062] 4) Import the waste liquid obtained in the previous step into the calcification tank, add milk of lime, and adjust to pH=7;

[0063] 5) Pump the waste liquid and sediment obtained in the previous step to the filter press for filtration;

[0064] 6) Discharge the filter press effluent obtained in the previous step to the comprehensive pool of the wastewater station for subsequent coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com