Quaternary ammonium salt grafted guanidine salt bactericide and preparation method thereof

A technology of quaternary ammonium salts and fungicides, which is applied in the field of fungicides grafted with quaternary ammonium salts and its preparation, can solve the problems of easy loss of fungicides, inability to sterilize for a long time, and inability to maximize the synergistic effect of fungicides, etc. Achieve the effect of good long-lasting killing performance, avoiding drug resistance and increasing surface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

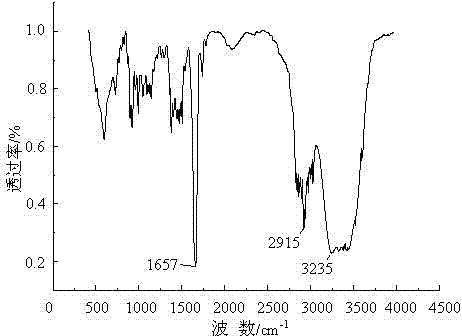

Embodiment 1

[0062] (1) Synthesis of PGA:

[0063] Add 14.8 grams (0.2mol) of propylenediamine, 103 grams (1mol) of diethylenetriamine, and 114.6 grams (1.2mol) of powdered guanidine hydrochloride into a 500ml three-necked flask and stir, and blow in nitrogen to continuously discharge ammonia , raise the reaction temperature to 80°C, after 2 hours of reaction, the viscosity of the material increases, and continue to react for 8 hours after rising to 180°C, the viscosity of the material increases rapidly, speed up the stirring speed to 250rpm, extract the by-product ammonia, and vacuumize to 1000pa to promote the reaction Carry out, keep 1h after vacuuming, then rapidly cool the reaction material to 90 ° C, take out the product, cool to room temperature and weigh, obtain 190 grams of polyguanidine salt, after drying, measure its intrinsic viscosity to be 0.11dl / g, to The minimum inhibitory concentration (MIC) of Escherichia coli is 75ppm;

[0064] (2) Synthesis of CHA:

[0065] Add 107 gr...

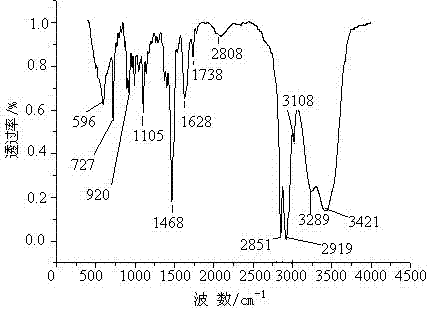

Embodiment 2

[0074] (1) Synthesis of PGA: Weigh 30.0 g (0.2 mol) of ethylenediamine, 103 g (1 mol) of triethylenetetramine, and 159 g (1.3 mol) of powdered guanidine nitrate, add them to a 500ml three-neck flask and stir , feed nitrogen, raise the reaction temperature to 90°C, continuously discharge ammonia gas, after 2 hours of reaction, the viscosity of the material increases, rise to 160°C and continue the reaction for 10 hours, the viscosity of the material increases rapidly, speed up the stirring speed to 250rpm, and vacuumize to 800pa , quickly pump out the by-product ammonia to promote the reaction, keep it for 3 hours after vacuuming, and then quickly cool the reaction material to 90°C to obtain 240 grams of polyguanidine salt. After drying, the intrinsic viscosity is 0.09dl / g , the minimum inhibitory concentration of polyguanidine salt to Escherichia coli is 86ppm;

[0075] (2) Synthesis of CHA: Add 121 grams (0.5 mol) of tetradecyl tertiary amine into a 500 ml three-necked flask,...

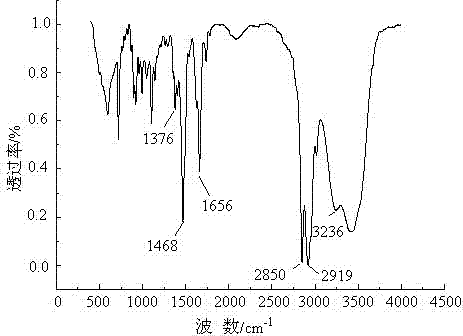

Embodiment 3

[0078](1) Synthesis of PGA: Weigh 123 grams (1.2mol) of diethylenetriamine and 118 grams (1.44mol) of powdered guanidine hydrochloride, add them into a 500ml three-neck flask and stir, and then blow in nitrogen, and raise the reaction temperature to When the temperature reaches 100°C, the ammonia gas is discharged continuously. After reacting for 2 hours, the viscosity of the material increases slowly, and continues to rise to 170°C. After continuing to react for 10 hours, the viscosity of the material increases rapidly. Speed up the stirring speed, and evacuate to 700pa to quickly remove the side effects. The product ammonia gas promotes the equilibrium reaction to the right. After vacuuming, it is kept for 2 hours, and then the reaction material is rapidly cooled to 90°C to obtain 190 grams of polyguanidine salt. After drying, the intrinsic viscosity is 0.12dl / g. The minimum inhibitory concentration (MIC) of guanidine salt to Escherichia coli is 90ppm;

[0079] (2) Synthes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com