Aramid fiber-reinforced rein-based composite material and preparation method thereof

A technology for reinforcing resin-based and aramid fibers, which is applied in fiber types, fiber treatment, textiles and papermaking, etc. It can solve the problems of low grafting on the surface of Kevlar fibers, low ratio of biological enzymes to hydrogen peroxide, long-term polyacrylamide Poor stability and other issues, to achieve good swelling effect, not easy to chemical reaction or degradation, good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1. Preparation of aramid fiber coated with acrylate derivative polymer

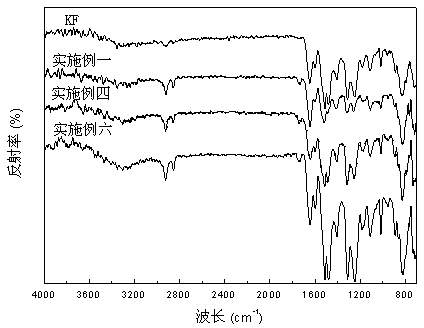

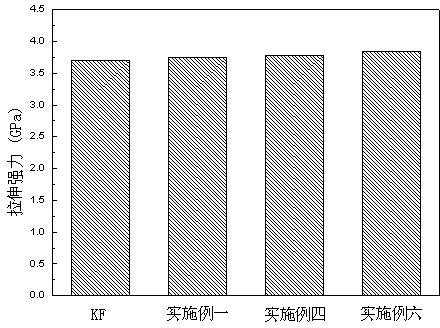

[0040] 1) Put the aramid fiber in acetone that can remove the surface attachment, let it stand for 6 hours to remove the dirt on the fiber surface, then wash it with water for 3 hours, dry it in vacuum and set it aside, it is unmodified aramid fiber Fiber, denoted as KF. Its surface morphology SEM photos, infrared spectrograms, tensile properties, contact angles, ultraviolet light and 20wt% phosphoric acid before and after immersion in 24 hours of tensile properties of KF fibers are shown in figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and shown in Table 1.

[0041] 2) Take a total of 0.68g of potassium dihydrogen phosphate and sodium chloride, 20.5ml of 0.1mol / L sodium hydroxide, dilute with water to 100ml, and prepare a PBS buffer solution with a pH value of 6.8.

[0042] 3) Under the protection of nitrogen, put 1g of KF aramid fiber into a three-necked flask, add 20ml of PBS bu...

Embodiment 2

[0051] 1. Preparation of aramid fiber coated with acrylate derivative polymer

[0052] 1) Take 1.20g of sodium dihydrogen phosphate and sodium chloride in total, 13.2ml of 0.1mol / L potassium hydroxide, dilute to 100ml with water, prepare a buffer solution with a pH value of 6.5, and set aside.

[0053] 2) Under nitrogen protection, place 1g of KF aramid fiber in a three-necked flask, add 13.5ml of PBS buffer solution, add 50ml of N,N-dimethylformamide and water mixed solvent (N,N- The volume ratio of dimethylformamide to water is 2.6:1, and the solubility parameter of this mixed solvent is 15.3 cal 1 / 2 cm -3 / 2 ), 10mg of horseradish peroxidase, 85ml of glycidyl methacrylate, 40ml of hydrogen peroxide with a mass fraction of 0.1% was added dropwise, reacted at 45°C for 7 hours, and the aramid fiber was taken out.

[0054] 3) The aramid fibers obtained in step 2) were extracted with a mixed solution of water and acetone for 12 hours, and then vacuum-dried for 14 hours to obtai...

Embodiment 3

[0061] 1. Preparation of aramid fiber coated with acrylate derivative polymer

[0062] 1) Take 1.36g of potassium dihydrogen phosphate and 79ml of 0.1mol / L sodium hydroxide, dilute with water to 200ml, prepare a buffer solution with a pH value of 7.4, and set aside.

[0063] 2) Under nitrogen protection, place 1g of KF aramid fibers in a three-necked flask, add 100ml of PBS buffer solution, add 45ml of toluene, a mixed solvent of cyclohexanone and water (the volume of toluene, cyclohexanone and water The ratio is 1:2:2, and the solubility parameter of the mixed solvent is 15.0 cal 1 / 2 cm -3 / 2 ), 20mg of horseradish peroxidase, 65ml of hydroxypropyl methacrylate, 1ml of hydrogen peroxide with a mass fraction of 6% was added dropwise, reacted at 35°C for 30 hours, and the aramid fiber was taken out.

[0064] 3) The aramid fibers obtained in step 2) were extracted with a mixed solution of water and acetone for 5 hours, and then vacuum-dried for 17 hours to obtain polyhydroxypro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solubility parameter | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com