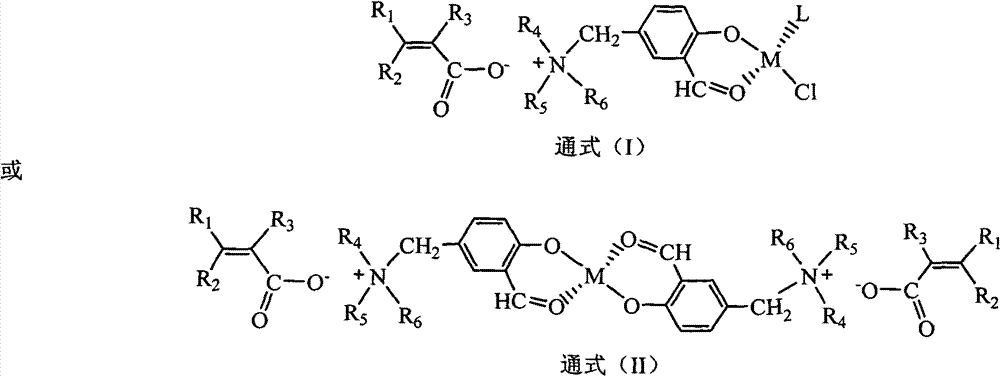

Polymerizable salicylic aldehyde complex containing quaternary ammonium salt and preparation method thereof

A technology of quaternary ammonium salt and salicylaldehyde, applied in the preparation of organic compounds, carboxylate salts, copper organic compounds, etc., can solve the problem of low biocidal activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

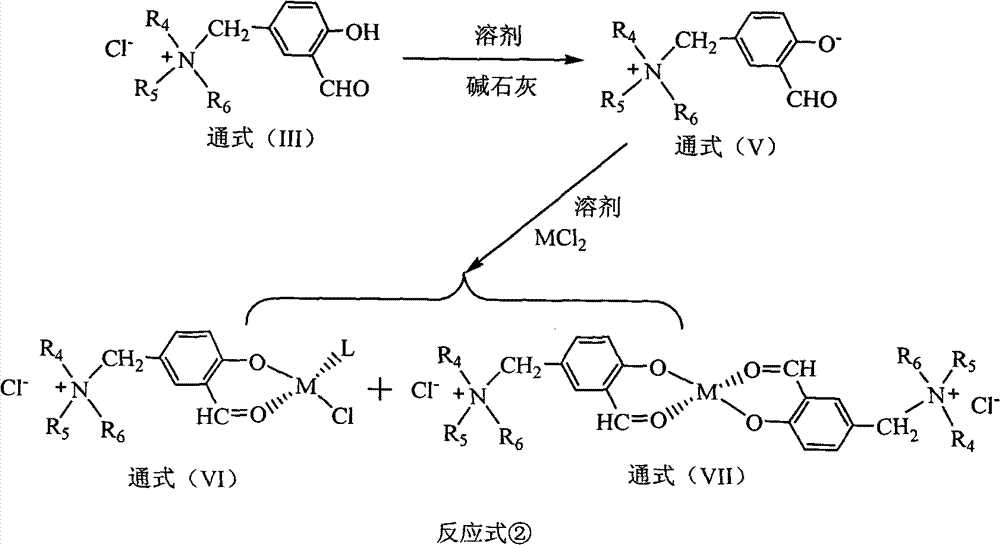

[0038] Example 1 Preparation of polymerizable salicylaldehyde / copper complex PQSC-1 containing quaternary ammonium salt

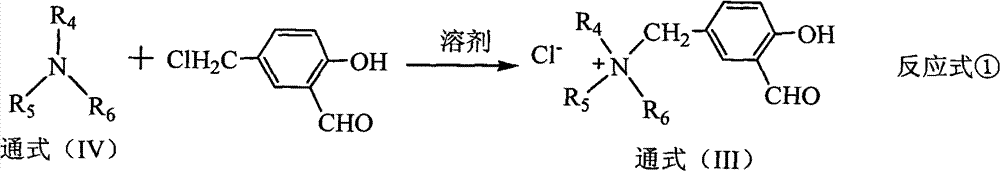

[0039] Step 1, the preparation of QS-1 quaternary ammonium salt replacing salicylaldehyde

[0040]

[0041] Weigh 70 grams of N,N-dimethylbenzylamine and 80 grams of 5-chloromethyl salicylaldehyde and dissolve them in 100 grams of ethyl acetate respectively to obtain the acetic acid of N,N-dimethylbenzylamine Ethyl ester solution and ethyl acetate solution of 5-chloromethyl salicylaldehyde, at room temperature, add the ethyl acetate solution of 5-chloromethyl salicylaldehyde to N,N-dimethylbenzylamine ethyl acetate solution After stirring and reacting for 4 hours, the temperature was raised to 60-65° C. and continued to stir and react for 6 hours. The reaction system was allowed to stand and naturally cooled to room temperature, filtered to obtain a white crystalline substance, recrystallized, and dried to obtain 132 grams of QS-1 type quaternary ammoni...

Embodiment 2

[0048] Example 2 Preparation of polymerizable salicylaldehyde / copper complex PQSC-2 containing quaternary ammonium salt

[0049]

[0050] According to the method and operation steps of Example 1, the N,N-dimethylbenzylamine in Example 1 was replaced with tributylamine to prepare the polymerizable salicylaldehyde / copper complex PQSC-2 containing quaternary ammonium salt.

Embodiment 3

[0051] Example 3 Preparation of polymerizable salicylaldehyde / copper complex PQSC-3 containing quaternary ammonium salt

[0052]

[0053] According to the method and operation steps of Example 1, the N,N-dimethylbenzylamine in Example 1 is replaced by N,N-dimethyldodecylamine, and the polymerizable salicylic acid containing quaternary ammonium salt is obtained Aldehyde / copper complex PQSC-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com