Method for preparing praseodymium-doped ion exchange aluminate and germanate glass waveguide

A technology of aluminum germanate and doping ions, which is applied in the field of rare earth doped optical device preparation, can solve the problems of high use cost of photodynamic therapy equipment, damage to human body's healthy tissue, limited life, etc., to ensure uniformity and transparency, Good chemical stability, the effect of improving moldability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

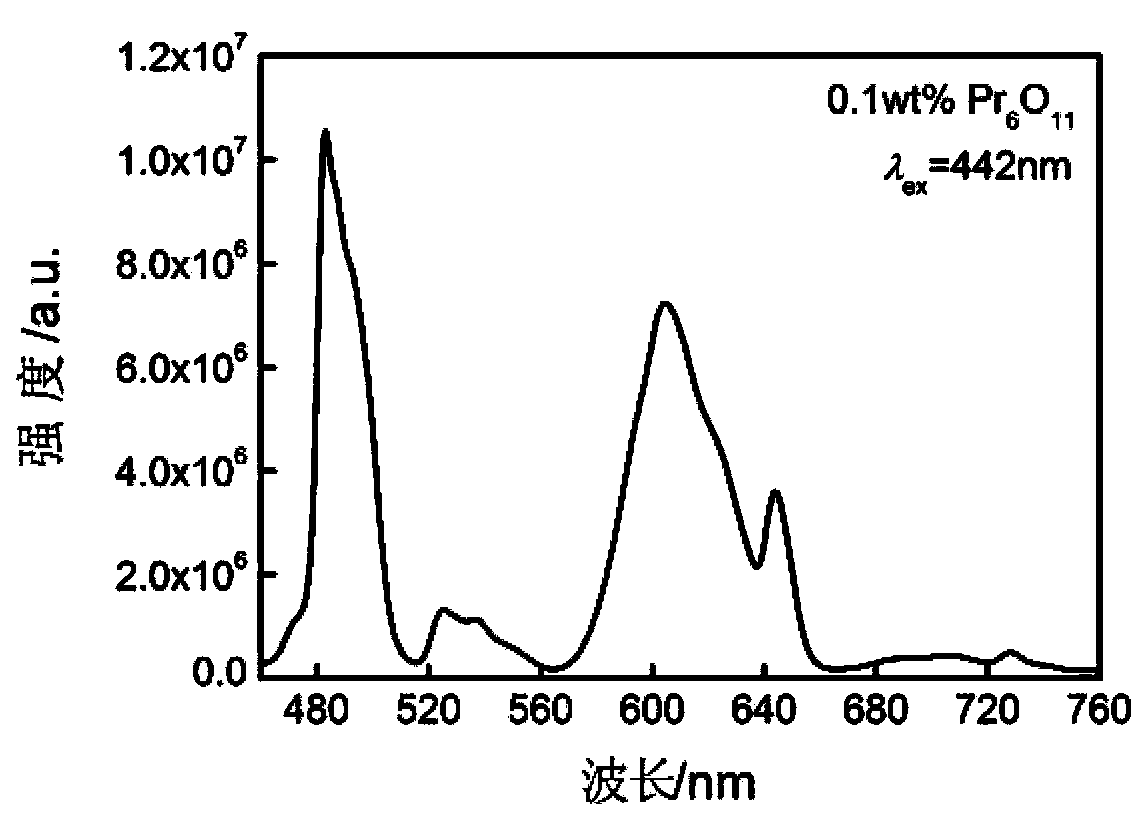

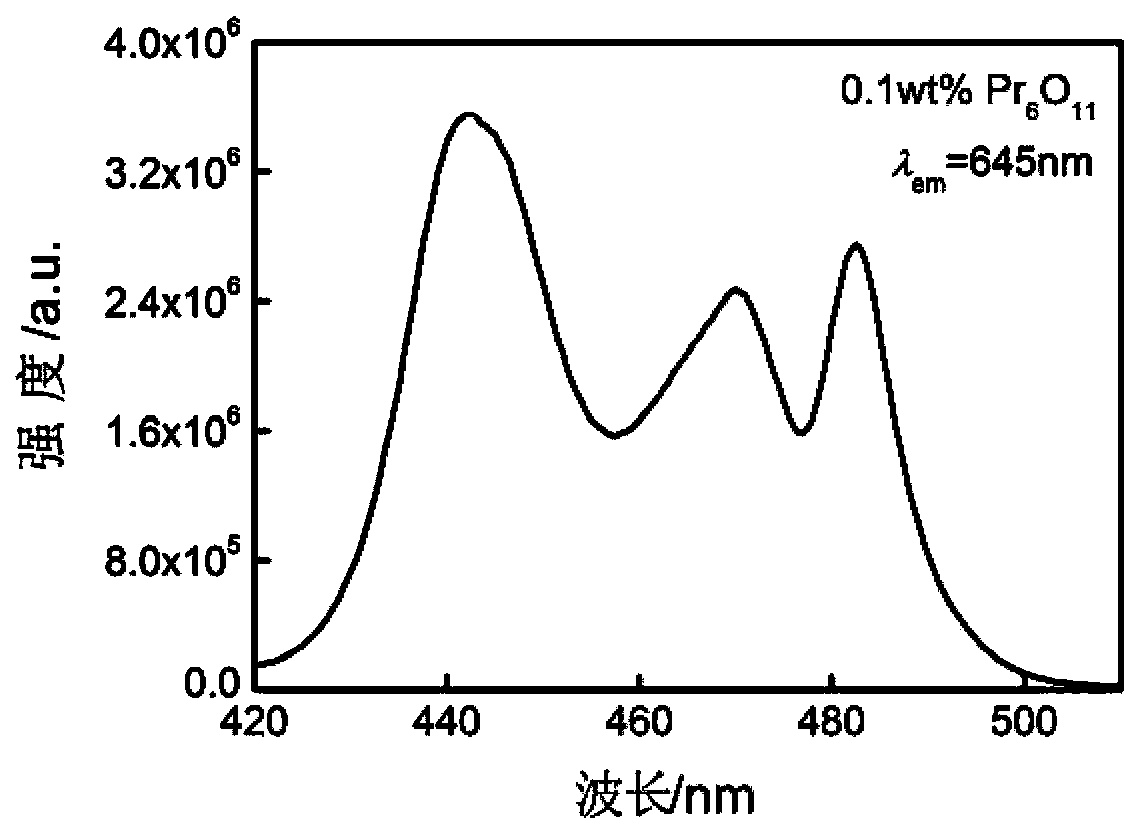

Embodiment 1

[0041] (1) Adopt the following molar ratio: sodium carbonate (Na 2 CO 3 ): Magnesium Oxide (MgO): Aluminum Oxide (Al 2 o 3 ): germanium oxide (GeO 2 )=25:2:20:53, weigh the above matrix raw materials, and weigh 0.1% of the total mass of matrix raw materials for praseodymium oxide (Pr 6 o 11 ) as a dopant, the purity of all raw materials is 99.99%, and the specific ingredients are shown in Table 1.

[0042] Table I

[0043] raw material

Na 2 CO 3

MgO

al 2 o 3

GeO 2

PR 6 o 11

mass (g)

8.744

0.266

6.729

18.301

0.034

[0044] (2) Put the raw materials weighed according to the method described in step (1) into an agate mortar and mix them thoroughly. After they are evenly mixed, pour them into a pure alumina crucible and place them in a box-type resistance furnace. Min heating rate, the temperature was raised to 500°C, and then the temperature was continued to rise at a rate of 5°C / min. T...

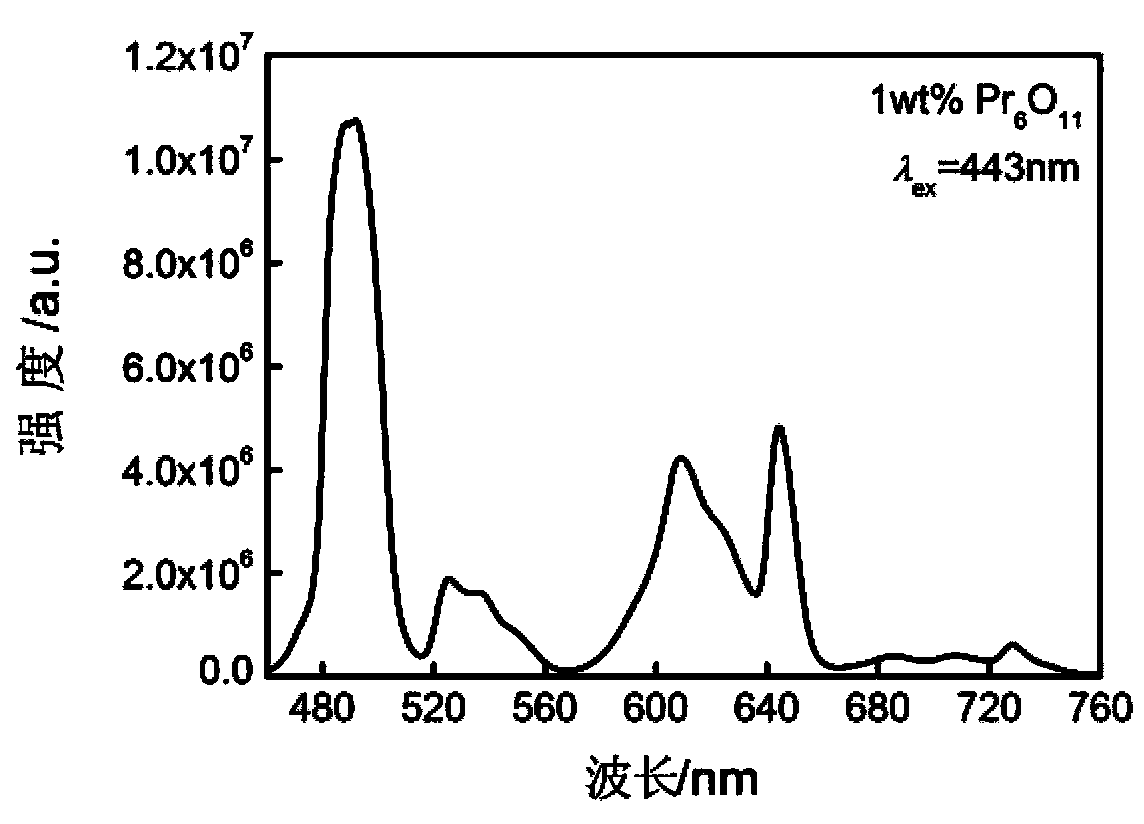

Embodiment 2

[0050] (1) Adopt the following molar ratio: sodium carbonate (Na 2 CO 3 ): Magnesium Oxide (MgO): Aluminum Oxide (Al 2 o 3 ): germanium oxide (GeO 2 )=22:2:24:50, weigh the above matrix raw materials, and weigh praseodymium oxide (Pr 6 o 11 ) as a dopant, the purity of all raw materials is 99.99%, and the specific ingredients are shown in Table 2.

[0051] Table II

[0052] raw material

Na 2 CO 3

MgO

al 2 o 3

GeO 2

PR 6 o 11

mass (g)

7.695

0.532

8.075

17.265

0.336

[0053] (2) Put the raw materials weighed according to the method described in step (1) into an agate mortar and mix them thoroughly. After they are evenly mixed, pour them into a pure alumina crucible and place them in a box-type resistance furnace. Min heating rate, the temperature was raised to 500°C, and then the temperature was continued to rise at a rate of 5°C / min. The furnace was cooled to room temperature (approxi...

Embodiment 3

[0059] (1) Select the glass sample prepared in Example 2, process it into a glass substrate with a size of 3cm×1.5cm×0.1cm and smooth surfaces on both sides, and first place the glass substrate in a trichloroethane solution for Ultrasonic cleaning for ten minutes to clean the surface oil; then immerse the substrate in acetone solution for five minutes to remove trichloroethane; then immerse the substrate in isopropanol for five minutes to remove residual acetone; finally rinse off the isopropyl with deionized water To remove residual stains from alcohol, dry the surface of the substrate with nitrogen.

[0060] (2) Potassium nitrate (KNO 3 ) The quartz crucible of molten salt is placed in an ion exchange furnace. After the temperature rises to 380°C and stabilizes, the glass substrate treated in step (1) is immersed in molten salt for ion exchange to prepare a planar optical waveguide. The ion exchange time for 2-6 hours. After the ion exchange process, the glass substrate is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com