Preparation method of nano patterned sapphire substrate

A patterned sapphire and sapphire substrate technology, which is applied in chemical instruments and methods, nanotechnology, semiconductor/solid-state device manufacturing, etc., can solve the problems of expensive equipment, complicated process technology, high cost, etc., and achieve simple and repeatable preparation process Good, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

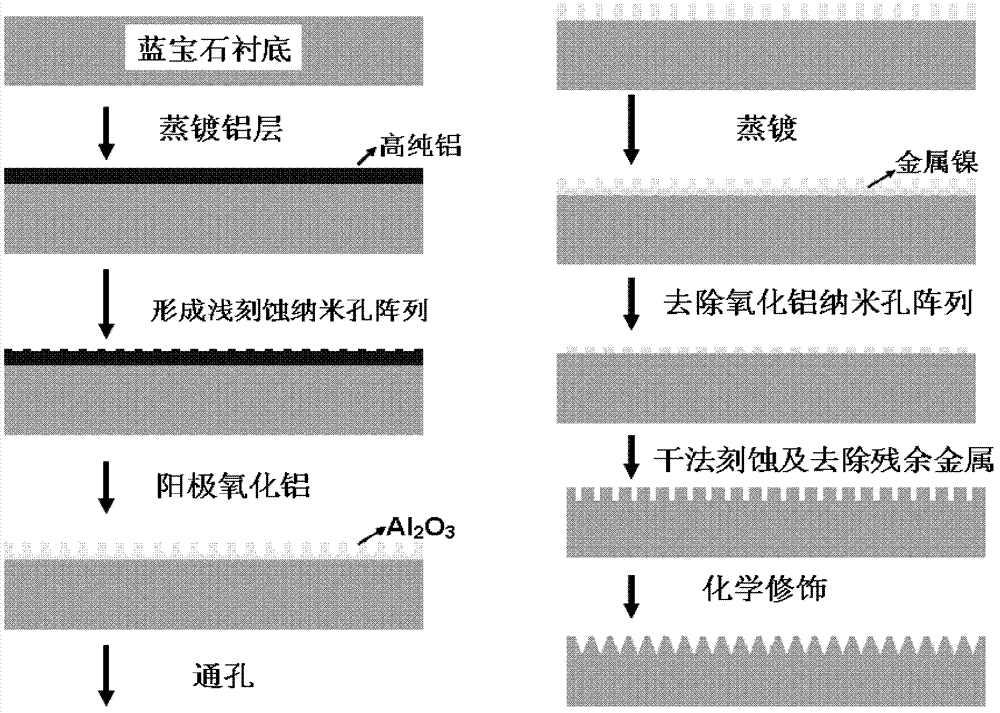

[0018] Referring to the accompanying drawings, a nanopillar patterned sapphire substrate is prepared according to the following process flow.

[0019] 1. Ultrasonic cleaning of sapphire with acetone, ethanol, and deionized water in sequence;

[0020] 2. Coating a high-purity aluminum layer on the surface of sapphire, wherein the metal aluminum layer can be prepared by electron beam evaporation, magnetron sputtering and electroplating, with a thickness of 300-2000 nanometers;

[0021] 3. Prepare a template with a nanostructure, specifically: prepare a 2-inch aluminum oxide nanostructure array template with a pore period of 460 nanometers by using the method of anodizing aluminum, and the conditions for anodic oxidation are: the oxidation voltage is 190V, and the electrolyte is The 0.1mol / L phosphoric acid solution and the reaction temperature a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com