Lipase and engineering strain of recombinant expression thereof

A technology of lipase and engineering bacteria, applied in the field of microbial engineering, can solve the problems of hidden safety hazards and low expression level of Pichia pastoris, and achieve the effect of strong tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1 Construction of Aspergillus niger lipase gene expression vector

[0021] 1.1 Extraction of total genomic DNA from Aspergillus niger

[0022] Aspergillus niger (Aspergillus niger) was inoculated with shake flask medium for overnight culture, and an appropriate amount of bacteria was placed in a centrifuge tube, centrifuged at 13,000 rpm for 5 min, and the supernatant was discarded; 400 μl of extraction buffer (100 mM TrisHCl, 100 mM EDTA, 250 mM NaCl, 1% SDS); then add 100 mg of quartz sand or glass beads, shake vigorously in a bead beater for about 2 min; add 200 μl 10M NH4AC in a water bath for 20 min at 65°C and ice bath for 10 min; centrifuge at 13000 rpm for 10 min to take Add 2 times the volume of absolute ethanol to the supernatant and place at -20°C for 30 min; centrifuge at 13,000 rpm for 10 min to discard the supernatant, wash twice with 70% ethanol; air dry, add appropriate amount of water to dissolve and store at -20°C.

...

Embodiment 2

[0029] Example 2 Transformation and screening

[0030] 1.1 Protoplast preparation

[0031] Inoculate Trichoderma reesei mycelia and grow on PDA plates for 4 days; cut colonies with a diameter of about 3 cm and place them in liquid medium of about 60 ml YEG (0.5% yeast powder, 1% glucose) at 30°C, Shake culture at 200 rpm overnight; collect the mycelium by filtering with multi-layer gauze; place the mycelia in a 10-20 ml lysing enzyme solution (Sigma L1412) for 2-3 hours; take out the enzymatic solution, add 0.7 M NaCl solution, Shake lightly, pour on three layers of sterilized lens tissue and filter, collect the filtrate, centrifuge at 3000 rpm for 10 min; discard the supernatant, add 10-20 ml STC solution (20% sucrose, 50mM Tris-Cl, 50mM CaCl 2 ) suspension, 3000 rpm, centrifuged for 10 min; add an appropriate amount of STC suspension (150 μl / tube, 10 8 pieces / ml).

[0032] 1.2 Transformation and verification

[0033] Take 2 μg pKDN-ANL DNA and add it to 150 μl protoplast...

Embodiment 3

[0035] Example 3 Fermentation Verification and Enzymatic Properties Determination

[0036] The positive transformant Trichoderma reesei ZQ-1 and the starting strain (negative control) were inoculated in MM fermentation medium (1.5% glucose, 1.7% lactose, 2.5% corn steep liquor, 0.44% (NH 4 ) 2 SO 4 , 0.09%MgSO 4 , 2%KH 2 PO 4 , 0.04%CaCl 2 , 0.018% Tween-80, 0.018% trace elements, 0.018% polypropylene glycol-2000) culture, culture at 28°C for 48 hours, then culture at 25°C for 48 hours, take the supernatant for SDS-PAGE electrophoresis detection, the results are as follows figure 1 As shown, wherein the place indicated by the arrow is the recombinantly expressed lipase, indicating that the Trichoderma reesei engineered bacterium constructed in the present invention can recombinantly express the lipase of Aspergillus niger.

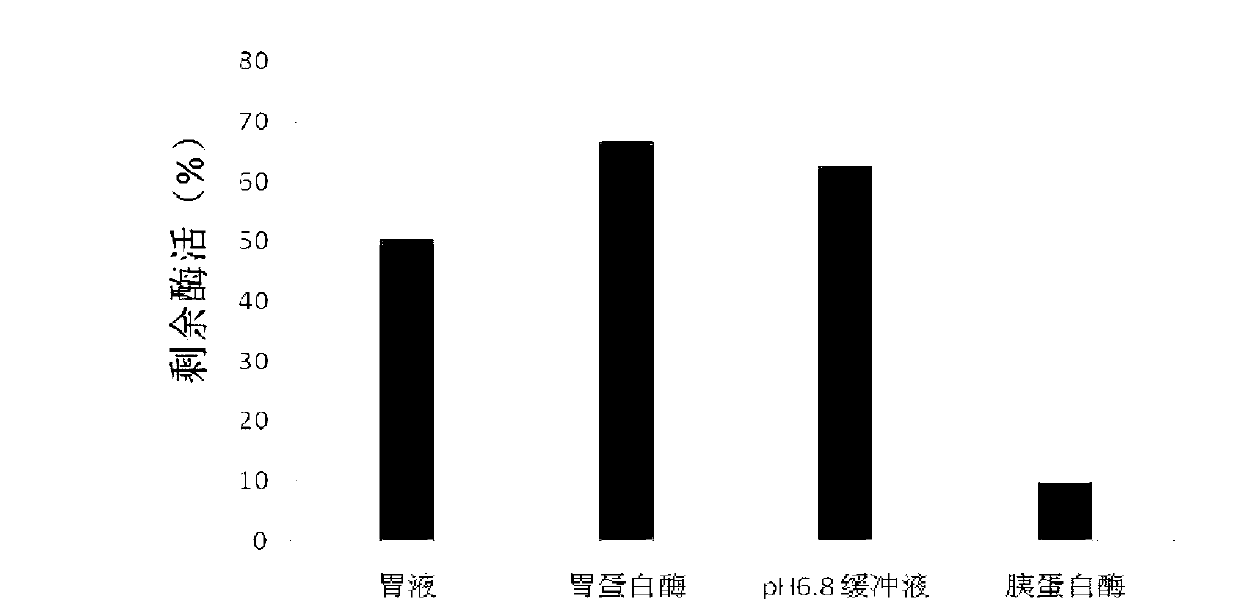

[0037] Optimum action pH analysis: the results of dilution test with buffers with pH values of 3.0, 4.0, 5.0, 6.0, 7.0, and 8.0 showed that the op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com