A kind of manufacturing method of the photovoltaic cell of high open circuit voltage

A manufacturing method and open-circuit voltage technology, applied in photovoltaic power generation, final product manufacturing, sustainable manufacturing/processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

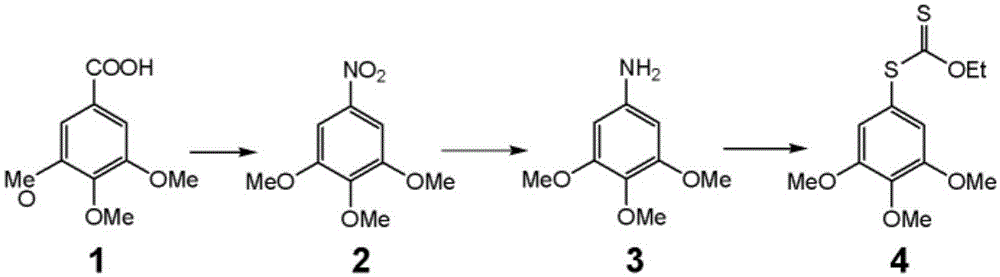

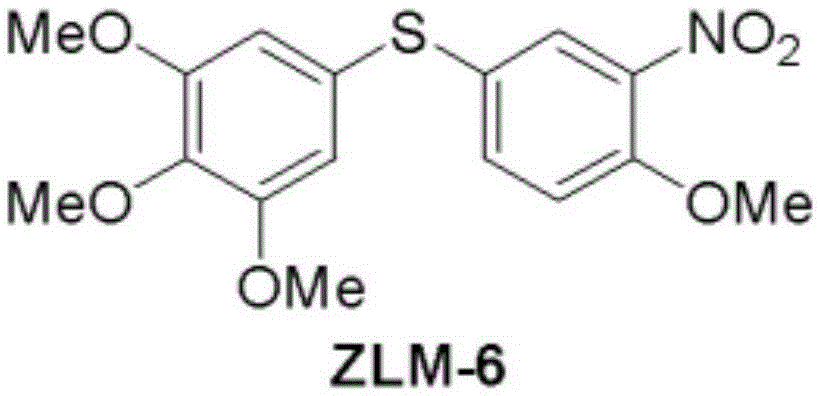

[0073] Preparation of 3,4,5-trimethoxy-1-[(3-nitro-4-methoxyphenyl)thio]benzene (ZLM-6)

[0074]

[0075] O-ethyl-S-(3,4,5-trimethoxyphenyl)dithiocarbonate ZLM-1 (2.42 g) was dissolved in THF (32 mL), and LiAlH was slowly added in portions 4 (1.3g), refluxed for 1 h, cooled to room temperature, adjusted to pH=5 with 10% HCl, extracted with EA for 20 mL×4, combined with the organic phases, dried over anhydrous sodium sulfate for 1 h, and filtered with suction to obtain the filtrate, spin The solvent was removed to obtain a yellow oil. Under nitrogen protection, potassium carbonate (1.16g, 8.40mmol, 2.0eq), CuI (400mg, 2.10mmol, 0.5eq) and ethylene glycol (0.49mL, 8.40mmol, 2.0eq) were first added to a 25mL two-neck flask , and then the yellow oil obtained in the previous step was dissolved in isopropanol (4.0 mL), then added to the reaction flask, refluxed at 80 ° C for 20 h, cooled to room temperature, suction filtered, and the filter residue was washed several times with ...

Embodiment 2

[0077] Preparation of 3,4,5-trimethoxy-1-[(3-amino-4-methoxyphenyl)thio]benzene (ZLM-7)

[0078]

[0079] According to Example 1, use 3,4,5-trimethoxy-1-[(3-nitro-4-methoxyphenyl)thio]benzene ZLM-6 (300 mg) instead of 1-(3'- Nitro-4'-methoxyphenyl)-2-methyl-5-(3',4',5'-trimethoxyphenyl)pyrrole ZLM-12 to give 181 mg of white solid, 66% yield , mp168.1-170.2℃. 1 HNMR (400MHz, CDCl 3 ): δ3.77(s, 6H), 3.81(s, 3H), 3.86(s, 3H), 6.50(s, 2H), 6.75(d, J=8.4Hz, 1H), 6.78(d, J= 2.4Hz, 1H), 6.83 (dd, J=6.4, 2.0Hz, 1H). 13 CNMR (400MHz, CDCl3): δ55.5, 56.0, 60.9, 106.4, 110.7, 118.6, 122.9, 125.3, 132.6, 136.4, 136.8, 147.2, 153.3. MS (EI) m / z: 321 (M + ).

Embodiment 3

[0081] Preparation of 3,4,5-trimethoxy-1-[(4-nitrophenyl)thio]benzene (ZLM-8)

[0082]

[0083] According to Example 1, use p-nitroiodobenzene (200mg) instead of 3-nitro-4-methoxyiodobenzene to obtain 194mg of pale yellow solid, yield 76%, mp 168.1-170.2 ℃. 1 HNMR (400MHz, CDCl 3 ): δ3.85(s, 6H), 3.91(s, 3H), 6.79(s, 2H), 7.17(d, J=8.8Hz, 2H), 8.09(d, J=8.8Hz, 2H). 13CNMR (400MHz, CDCl3): δ56.3, 61.0, 112.0, 124.1, 124.2, 125.9, 138.4, 145.1, 149.1, 154.1. MS (EI) m / z: 321 (M + ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com