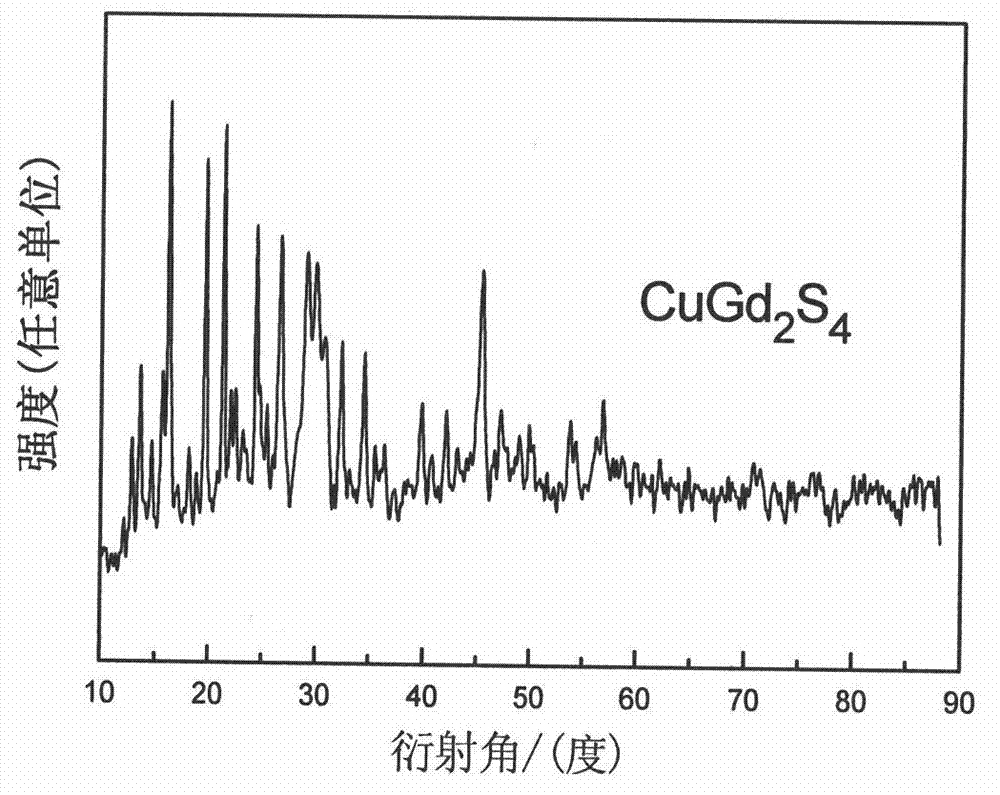

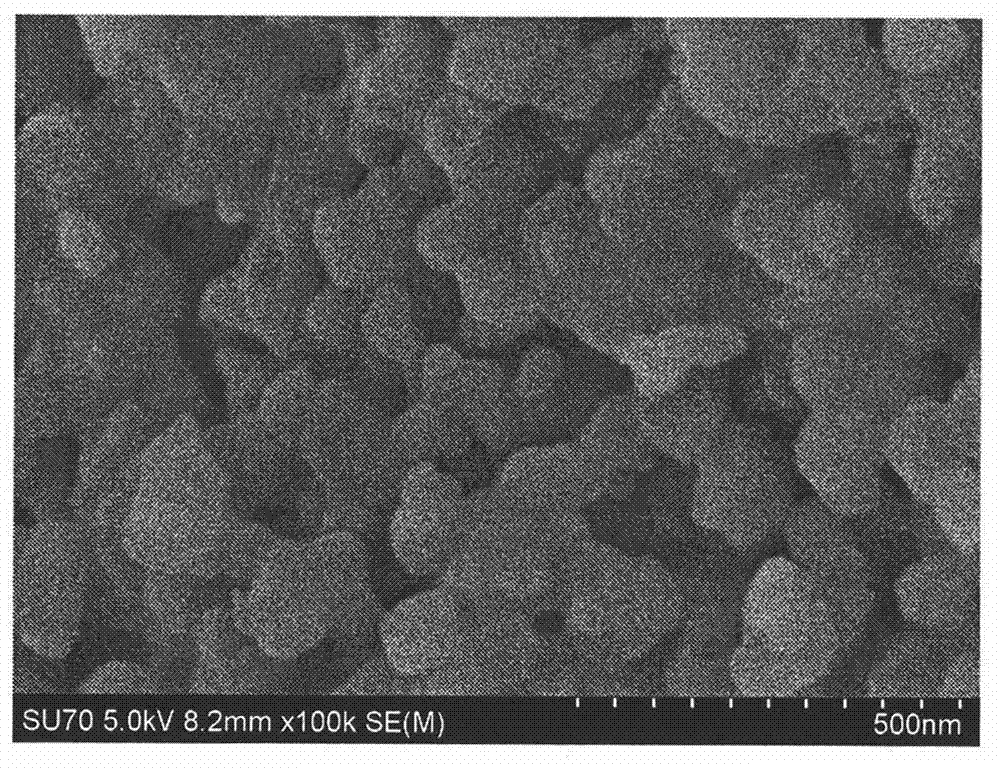

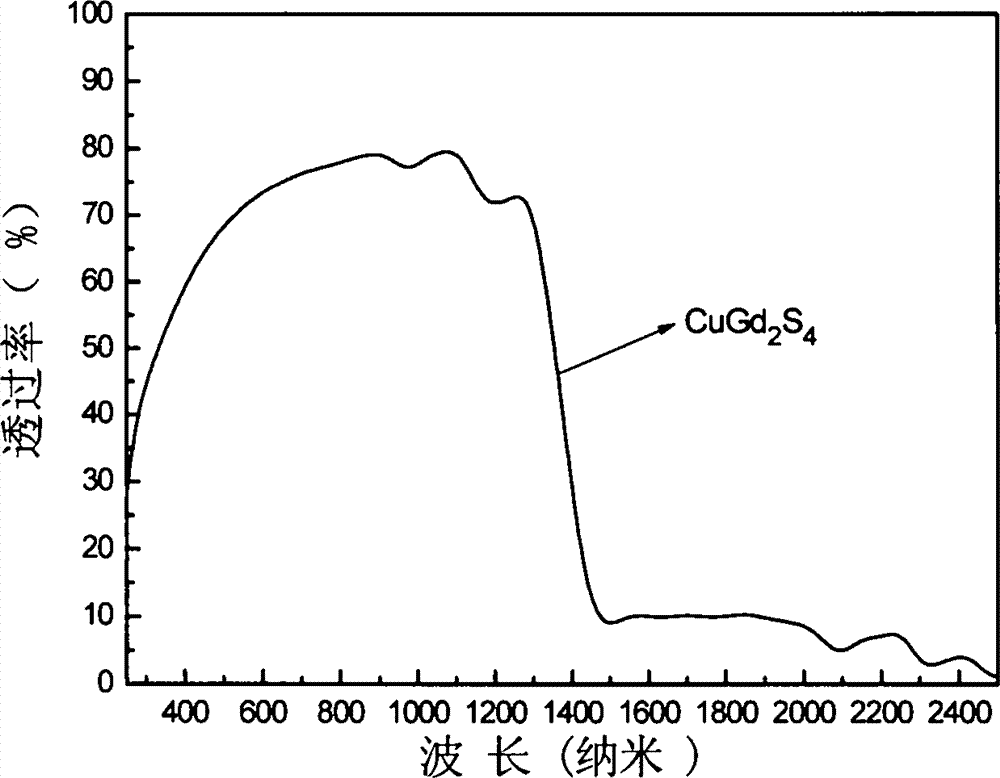

Preparation method of nanometer copper gadolinium sulfide powder and film containing nanometer copper gadolinium sulfide

A technology of nanometer copper gadolinium sulfide and nanometer powder is applied in the field of solar thermal insulation materials and achieves the effects of high yield, simple preparation equipment and high synthesis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Dissolve copper nitrate in deionized water to form a concentration (0.05-0.30) of 0.10 mol / L copper nitrate solution, similarly prepare gadolinium nitrate to form a concentration of 0.10 mol / L gadolinium nitrate solution, and sodium sulfide to form a concentration of 0.10 mol / L sodium sulfide solution, use dilute hydrochloric acid or ammonia water to adjust the pH value of copper nitrate solution, gadolinium nitrate solution and sodium sulfide solution to 6-8 for use; put 2 liters of copper nitrate solution and 2 liters of gadolinium nitrate solution into the spray of ultrasonic atomization device Obtain copper nitrate / gadolinium nitrate mixed solution in the container, 4 liters of sodium sulfide solutions are packed in the reaction barrel of ultrasonic atomization device, the surface area of sodium sulfide solution in the reaction barrel is 30 square centimeters (can be 18 square centimeters, 50 square centimeters etc.), at an ultrasonic power of 20W, a frequency of 5...

Embodiment 2

[0024]It is basically the same as Example 1, except that the concentrations of copper nitrate solution, gadolinium nitrate solution and sodium sulfide solution are all 0.05 mol / liter, gadolinium nitrate solution is 4 liters, sodium sulfide solution is 6 liters, and the liquid flow rate in the ultrasonic spray head 300 ml / hour, the stirring speed is 90 rev / min, let it stand and age for 24 hours, put the cleaned solid material into an oven, and dry it for 3 hours at a drying temperature of 200°C, and add 5 milliliters of Water alcohol, wet grinding with ceramic balls for 1h, drying at 80°C for 8 hours, dry grinding with Φ25mm zirconia balls for 0.5h, the mass ratio of nano-copper gadolinium sulfide powder to hexadecylmethyl ammonium bromide is 1 : The ratio of 1.5, the ratio of the mass ratio of nano-copper gadolinium sulfide powder to polyvinyl alcohol is 1:8.

Embodiment 3

[0026] It is basically the same as Example 1, except that the concentration of copper nitrate solution, gadolinium nitrate solution and sodium sulfide solution is 0.3 mol / liter, gadolinium nitrate solution is 3 liters, sodium sulfide solution is 5 liters, and the liquid flow rate in the ultrasonic spray head 50 ml / hour, the stirring rate is 30 rev / min, standing and aging for 5 hours, the cleaned solid material is put into an oven, and dried at a drying temperature of 60°C for 6 hours, and 40 ml of no Water alcohol, wet grinding with ceramic balls for 4 hours, drying at 200°C for 4 hours, dry grinding with Φ25mm zirconia balls for 6 hours, the mass ratio of nano-copper gadolinium sulfide powder to hexadecylmethylammonium bromide is 1: The ratio of 3, the mass ratio of nano-copper gadolinium sulfide powder to polyvinyl alcohol is 1:15; under the dipping method with a pulling speed of 1-5 mm / s, the nano-copper gadolinium sulfide viscous liquid is evenly coated On the glass, the n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com