Biological medical controllable all-degradable material and preparation method thereof

A biomedical, fully degradable technology, applied in the direction of anodic oxidation, coating, etc., can solve the problems of limiting modification effect and application scope, accelerating the degradation of magnesium alloy matrix, and inducing Alzheimer's disease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

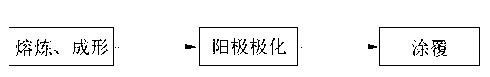

Method used

Image

Examples

Embodiment 1

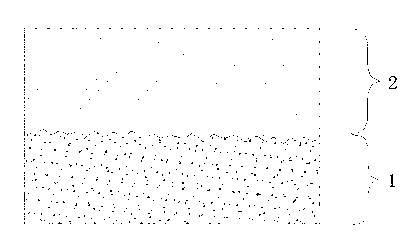

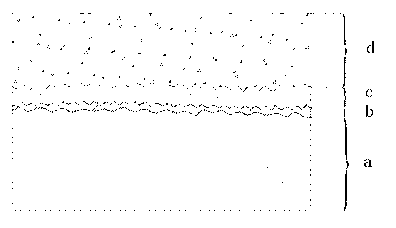

[0054] The sample of high-purity magnesium as cast metal was taken as the research object. Using distilled water as solvent, prepare 20.0g / L sodium chloride solution as anodic polarization electrolyte. Connect the equal-area samples of the same material to the wires, then connect them to the two output ports of the sinusoidal AC power supply, and immerse them in the above-mentioned electrolyte with a temperature control of 25°C, keep the distance between the samples at 3cm, and use a constant current of 1.0mA / cm at 50Hz 2 Treat for 30min. After washing and drying, it was found that the surface of the sample was uniformly distributed with finely divided pits of the same size and depth visible to the naked eye. Using dichloromethane as solvent, prepare 40.0g / LPLLA solution, marked as S 01 ; Use n-butanol as dispersant (liquid), add 10.0g / L magnesium oxide (solid dispersed phase), stir evenly to obtain a suspension, marked as S 02 ; With the homogeneous mixture of epichlorohyd...

Embodiment 2

[0057] The sample of AZ31 magnesium alloy in mold casting state was taken as the research object. Except that the electrolyte was changed to 20.0 mg / L sodium chloride solution prepared with deionized water, other conditions of anodic polarization were controlled the same as in Example 1. It was found that the treatment effect was the same as that of the implementation except that the density and depth of pits were reduced. example 1. In addition to changing the solvent into chloroform and the solute PLLA into PLGA, solution S 01 Other conditions of preparation are controlled with embodiment 1. In addition to changing magnesium oxide to magnesium hydroxide and pure magnesium powder (spherical, median particle size d 50 =47μm), β-TCP or CPP, solution S 02 Other conditions of preparation are controlled with embodiment 1, and corresponding solutions are respectively marked as S 02 -1, S 02 -2, S 02 -3 and S 02 -4. Dip-coat the washed and dried anodized sample according to ...

Embodiment 3

[0059] The sample of AZ91 magnesium alloy in mold casting state was taken as the research object. Except that the electrolyte was changed to 100.0g / L sodium chloride solution prepared with distilled water, the other conditions of anodic polarization were controlled the same as in Example 1. It was found that, except for the increase in the area of a single pit, the density of pits and the uniformity of their distribution Except reducing, other is with embodiment 1. Carry out solution S with embodiment 1 03 The preparation of -1. Use this solution to brush, spin and spray the washed and dried anodized samples respectively to obtain an areal density of 1.75 mg / cm 2 Uniform MgO / PLLA composite coating (functional film). The in vitro biodegradability test of the material was carried out the same as in Example 1, and the results showed that: the substrate of the sample began to have visible corrosion marks after about 42 days, indicating that the functional film had good biodeg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com