Preparation method of nickel foam base integral denitration catalyst with three-dimensional hierarchical structure

A technology of denitrification catalyst and hierarchical structure, which is applied in the field of preparation of nickel foam-based monolithic catalyst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Cut a 1×5 cm nickel foam into a roll, wash with ethanol and 1 mmol / L dilute hydrochloric acid for 15 min, and then rinse with deionized water. o After drying at C for 3 h, set aside;

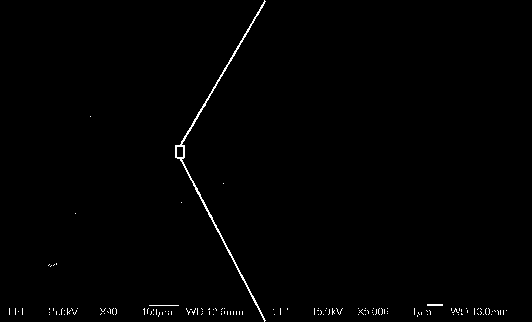

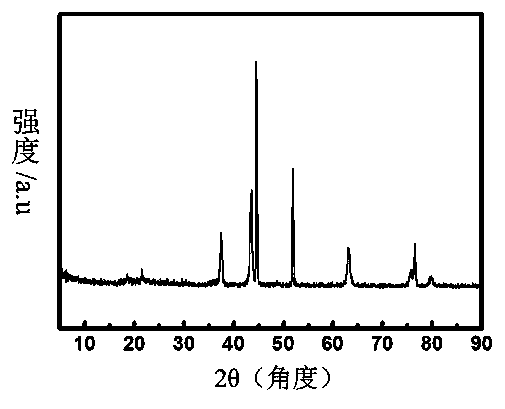

[0027] Put the treated nickel foam into the mixed solution of 0.05 mol / L manganese nitrate, 0.25 mol / L ammonium chloride and deionized water and fully immerse it for 1 h, then transfer it to the autoclave with a filling rate of 60% by volume , under the protection of stainless steel case, at 120 o C under the condition of reaction for 6 h, after natural cooling, the product was washed with deionized water, 60 o After drying at C for 3 h, in a tube furnace with 2 o C / min rate of heating up to 400 o C, heat preservation for 3 hours, and after cooling with the furnace, the monolithic denitration catalyst with a three-dimensional hierarchical structure can be obtained. The shape of the catalyst is as figure 1 As shown, the main component of catalyst surface active components is Ni-Mn so...

Embodiment 2

[0030] Cut a 1×5 cm nickel foam into a roll, wash with ethanol and 1 mmol / L dilute hydrochloric acid for 15 min, and then rinse with deionized water. o After drying at C for 3 h, set aside;

[0031] Put the treated nickel foam into the mixture of 0.10 mol / L manganese sulfate, 0.30 mol / L ammonium chloride and deionized water and fully immerse it for 1 h, then transfer it to the autoclave with a filling rate of 65% by volume , under the protection of stainless steel case, at 150 o C under the condition of reaction for 9 h, the product was washed with deionized water after natural cooling, 60 o After drying at C for 3 h, in a tube furnace with 2 o C / min rate of heating up to 500 oC, heat preservation for 4 hours, and after cooling with the furnace, the monolithic denitration catalyst with a three-dimensional hierarchical structure can be obtained.

[0032] Test the catalytic activity of the above catalyst: put the prepared catalyst into a fixed-bed quartz tube reactor for act...

Embodiment 3

[0034] Cut a 1×5 cm nickel foam into a roll, wash with ethanol and 1 mmol / L dilute hydrochloric acid for 15 min, and then rinse with deionized water. o After drying at C for 3 h, set aside;

[0035] Put the treated nickel foam into a mixture of 0.10 mol / L manganese chloride, 0.40 mol / L ammonium chloride and deionized water and fully immerse it for 1 h, then transfer it to a 100 ml high-pressure tank with a filling rate of 70% by volume. In the reaction kettle, under the protection of the stainless steel shell, at 170 o C under the condition of reaction for 12 h, after natural cooling, the product was washed with deionized water, 60 o After drying at C for 3 h, in a tube furnace with 2 o C / min rate heating up to 550 o C, heat preservation for 5 hours, and after cooling with the furnace, the monolithic denitration catalyst with a three-dimensional hierarchical structure can be obtained.

[0036] Test the catalytic activity of the above catalyst: put the prepared catalyst int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com